Construction method of bonded prestressed structure for reinforcing hollow slab bridge

A bonded prestressed, hollow slab bridge technology, applied in the direction of bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of not being able to improve the rigidity of the hollow slab structure, increasing the weight and size of the original structure, and the structural force is not necessarily beneficial, etc. Achieve light weight, improve structural rigidity, and reduce self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

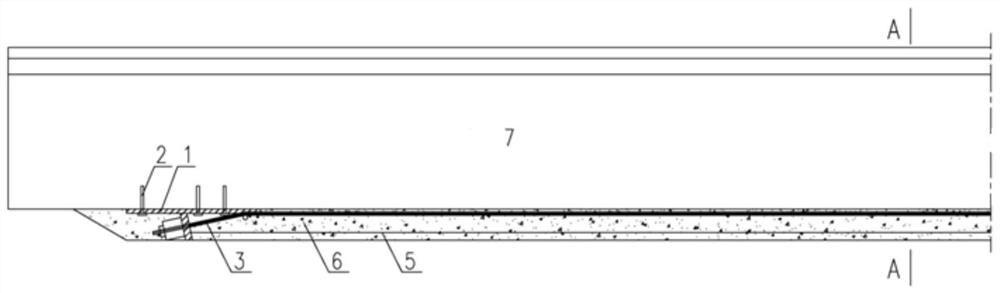

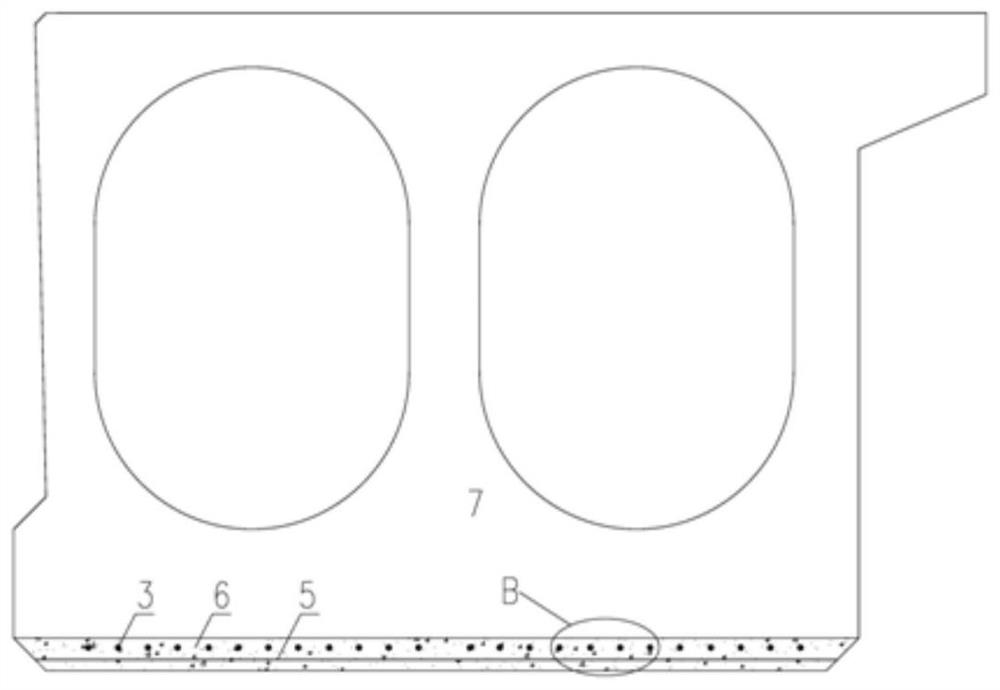

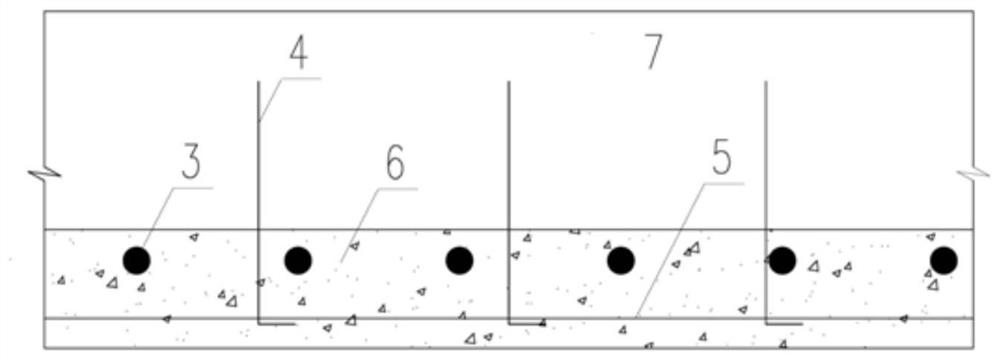

[0025] A construction method for a bonded prestressed structure used for hollow slab bridge reinforcement, comprising the following steps: first, make and install the anchor tooth plate according to the design drawings, and at the same time set the wire at the bottom of the beam to determine the position of the steel strand, and then cut For the construction of reinforcement reinforcement, the location of the reinforcement should avoid the steel strand; the second step, after the reinforcement is completed and the glue is solidified, the prestressed steel strand is threaded and initially fixed, and the steel strand is pre-tensioned to make it straight ; After the installation work is completed, stretch the prestressed steel strand; the third step is to spray high-strength tensile mortar in the range of the prestressed steel strand and the anchor tooth plate. Tensile mortar is injected in layers, and the thickness of each injection shall not be greater than 2cm; the fourth step,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com