An anti-seepage and anti-liquefaction floating sluice foundation and its construction method

A construction method and anti-liquefaction technology, applied in the direction of infrastructure engineering, construction, etc., to achieve the effect of increasing stability, strong operability, and low construction accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

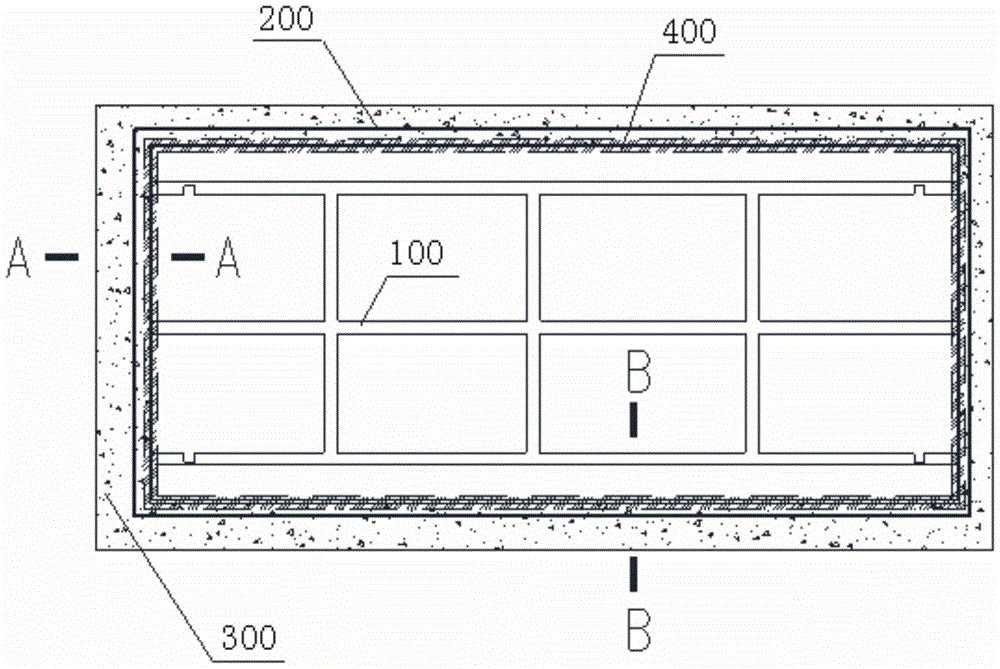

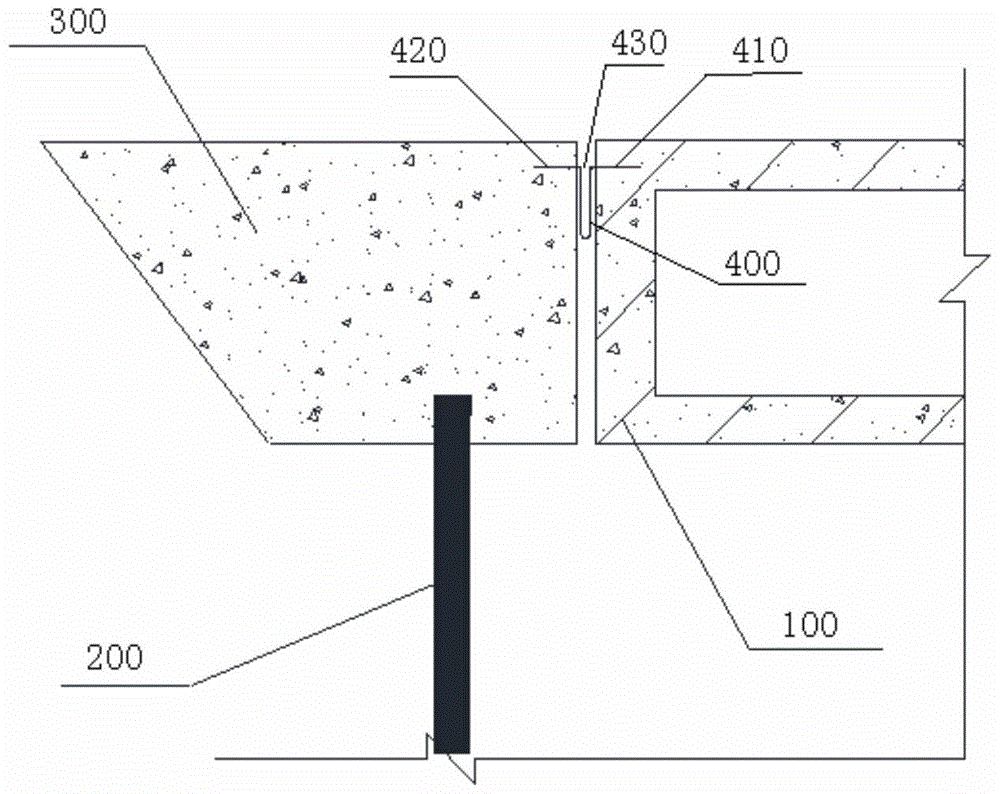

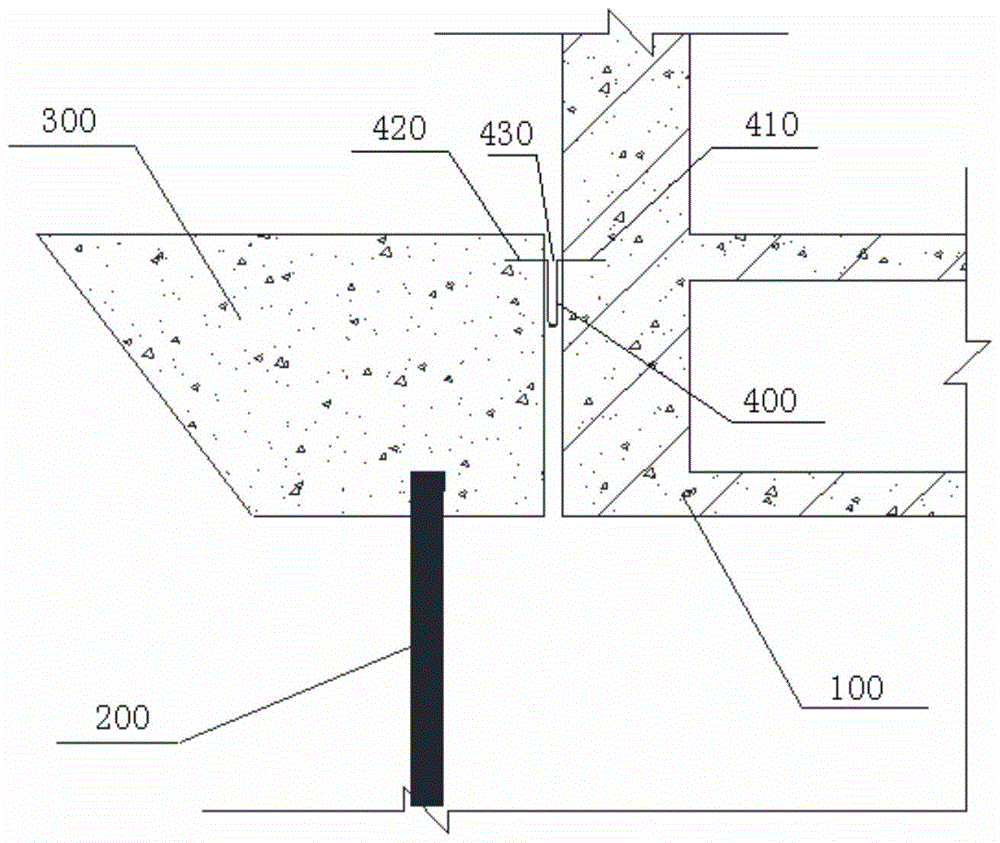

[0032] Referring to the accompanying drawings, a seepage-proof and liquefaction-resistant floating sluice foundation is shown in the figure, including an empty tank gate bottom plate 100, a continuous closed sheet pile 200, a concrete bottom plate 300 and a flexible sealing structure.

[0033] The bottom plate 100 of the empty box gate is placed on the foundation, and it is made of a reinforced concrete structure or a prestressed reinforced concrete structure.

[0034] The continuous closed sheet pile 200 is arranged around the bottom plate of the empty box gate 100 and sunk into the foundation, and it is formed by a sheet pile capable of forming a seal, such as a prefabricated reinforced concrete sheet pile, a steel sheet pile, and the like.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com