Connecting structure and construction method for assembly type bridge pier column and bearing platform

A construction method and technology for connecting structures, which are applied in basic structure engineering, bridges, bridge parts, etc., can solve the problem of not being able to take into account the reliability of connection and convenience of construction at the same time, so as to facilitate on-site assembly, improve reliability, and improve tight engagement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

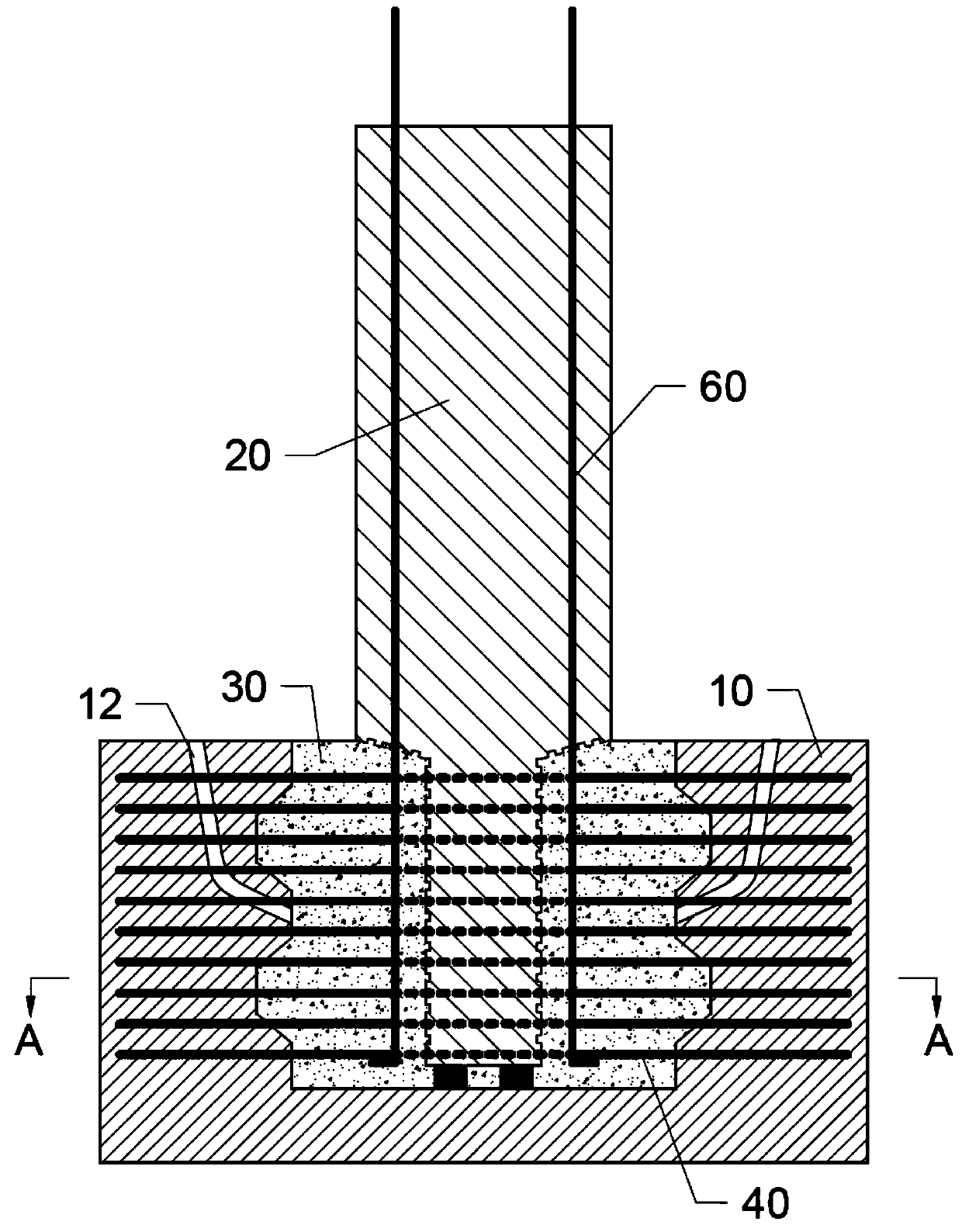

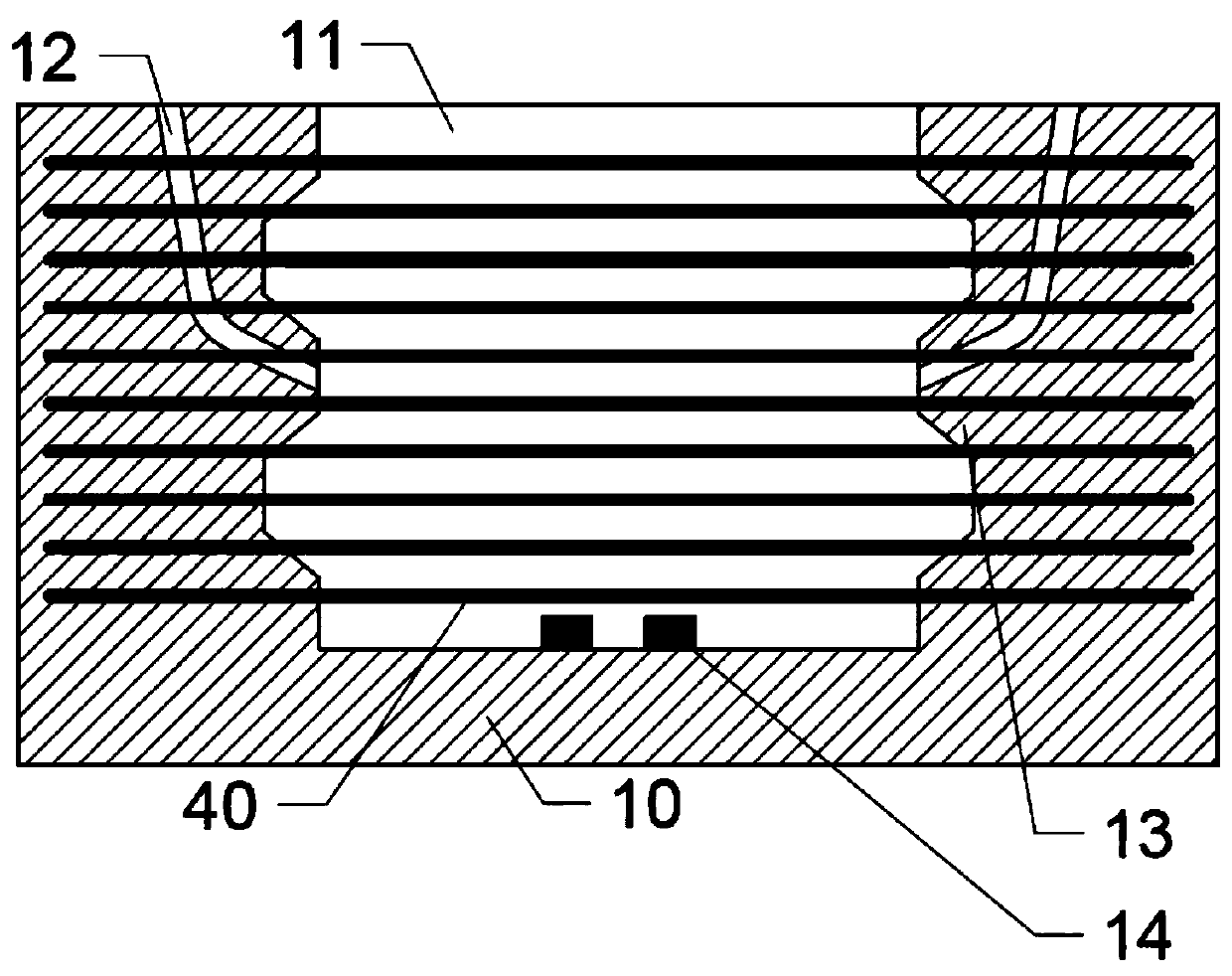

[0035] The present invention will be further described below in conjunction with the accompanying drawings and the following embodiments.

[0036] The first aspect of the embodiment of the present invention provides a construction method for a prefabricated bridge pier column and cap, including the following steps:

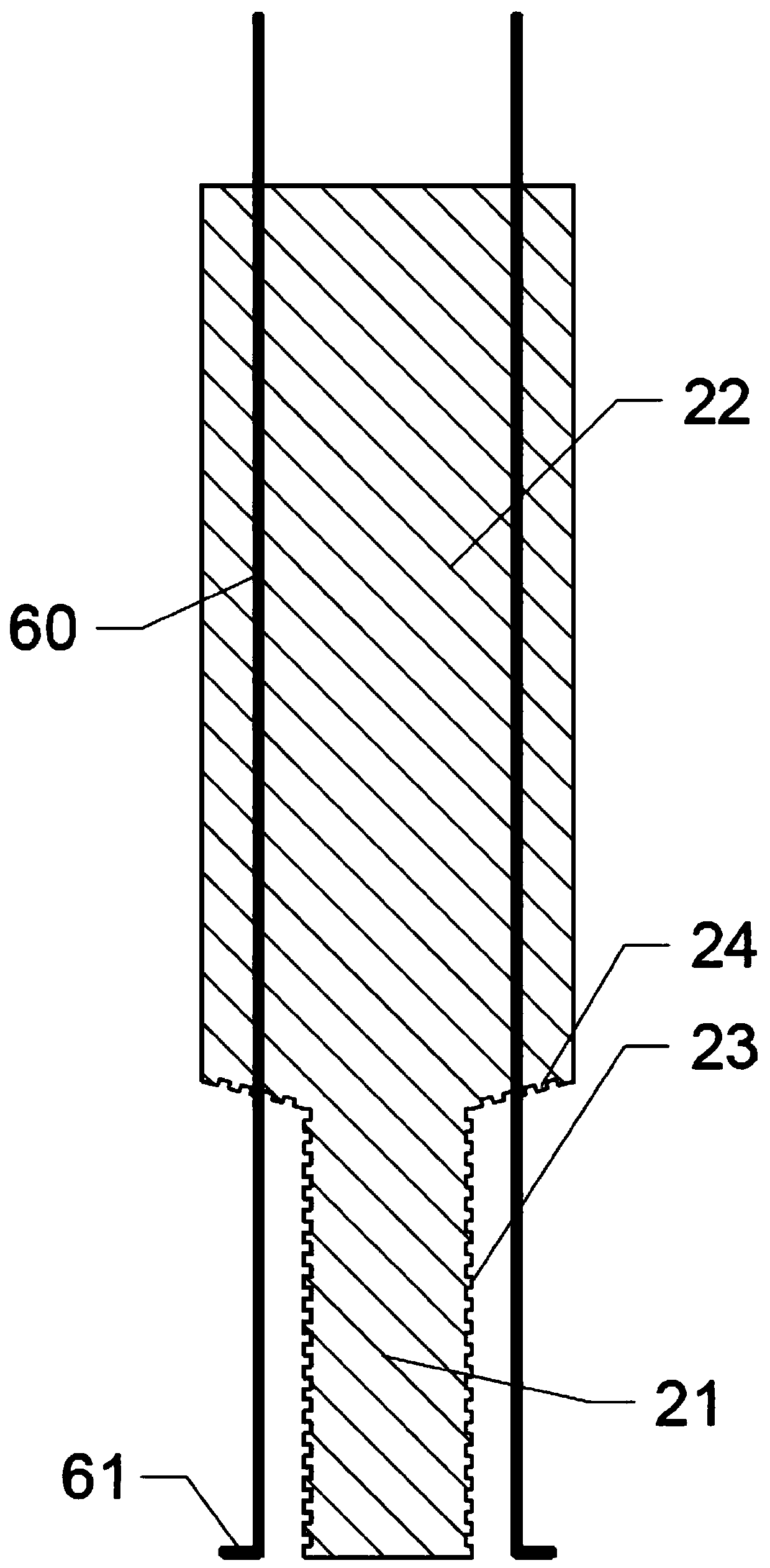

[0037] Step 1: Prefabricate the piers 20 .

[0038] Step 2: At the preset installation position of the pier column 20, fabricate the cap 10 with the cap reserved slot 11 on the upper end.

[0039] Step 3: Install the pier column 20 into the reserved platform slot 11 of the platform 10 .

[0040] Step 4: Press the grouting material 30 into the reserved slot 11 of the platform until the grouting material 30 is flush with the opening of the reserved slot 11 of the platform.

[0041] Wherein, step 1 includes: the first part 21 and the second part 22 of the prefabricated pier column 20, the outer diameter of the first part 21 is smaller than the second part 22, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com