Method for repairing top cover of large-diameter water taking head

A repair method and large-diameter technology, applied in water conservancy projects, artificial waterways, water supply devices, etc., can solve the problems of fatigue failure of the connection joint between the top cover and the side wall, the limited strength of the connection joint, and the deterioration of water quality, so as to reduce repairs. Cost and construction difficulty, good water flow, effect of resisting water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

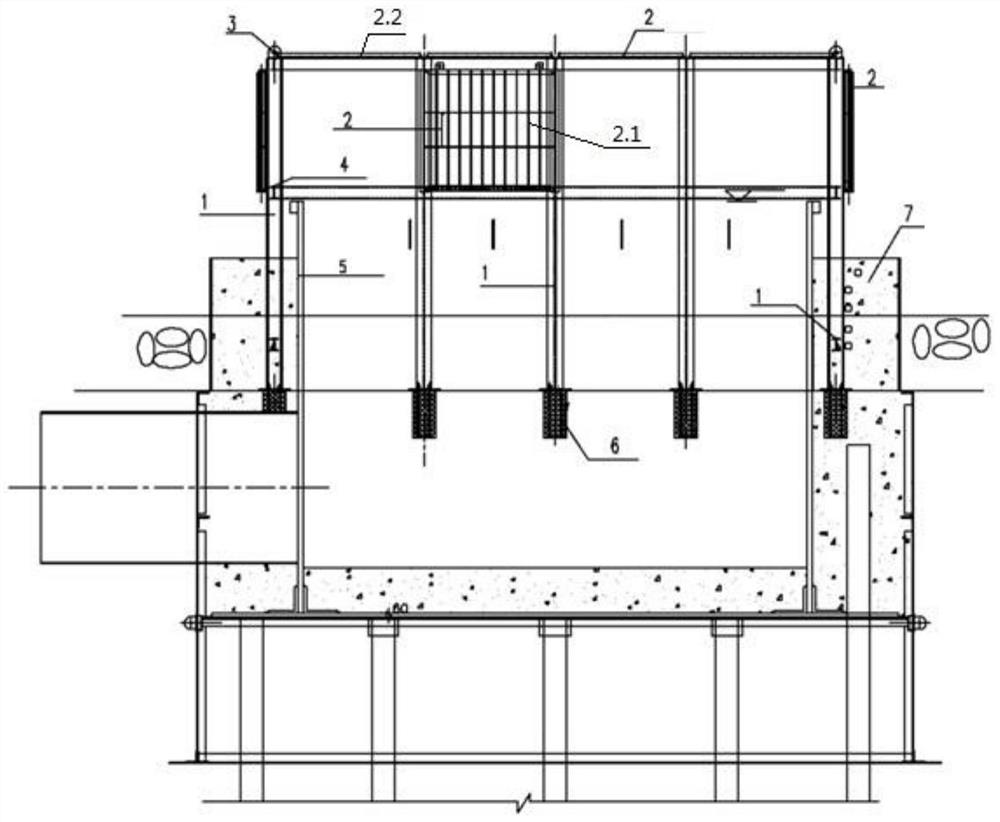

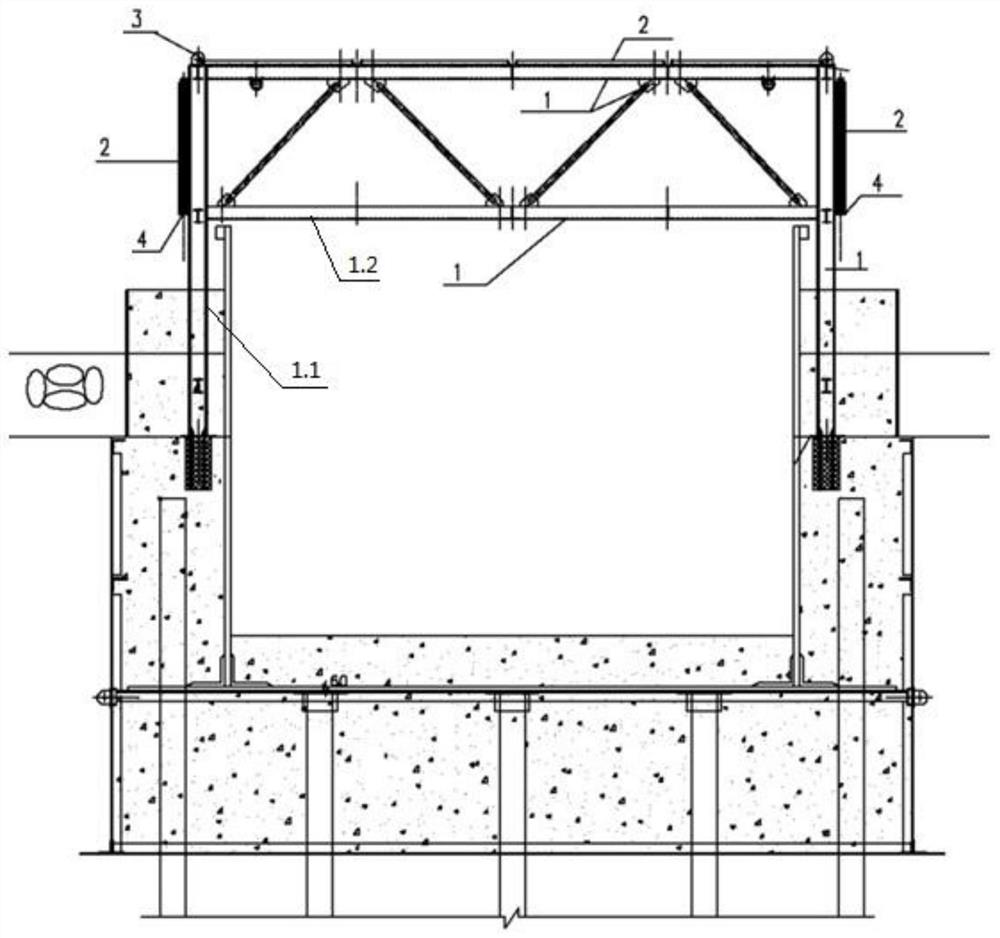

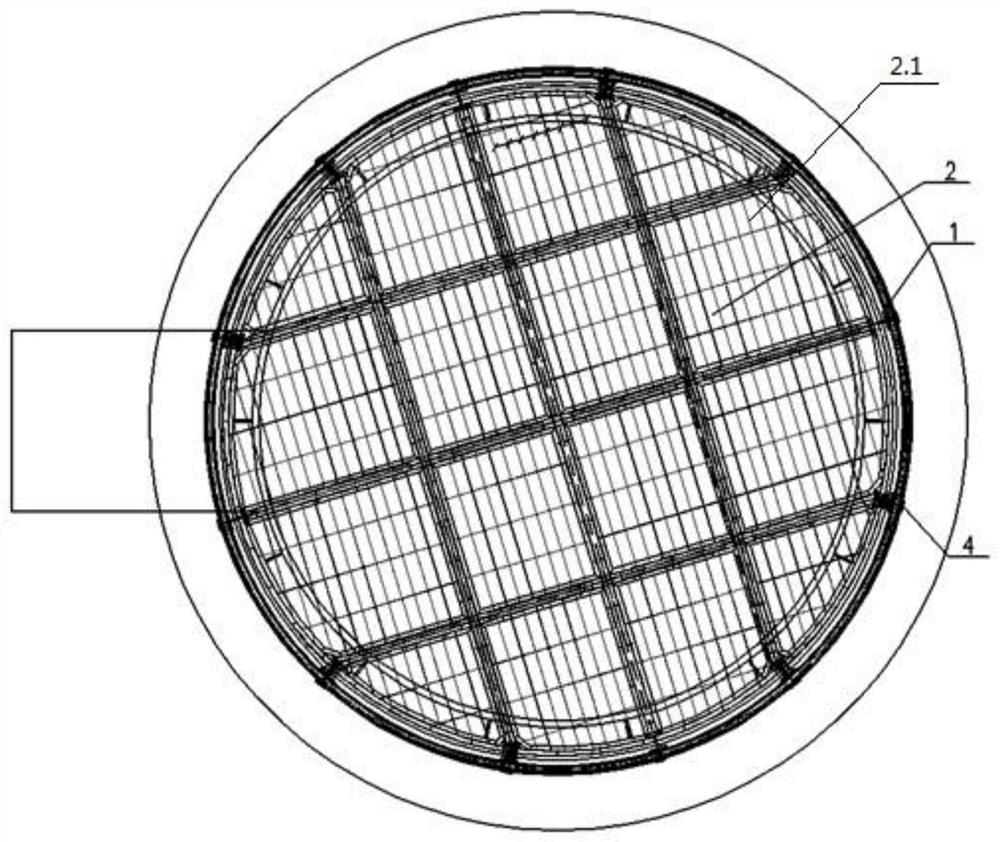

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

[0028] The invention provides a method for repairing the top cover of a large-diameter water intake head, which includes the following steps:

[0029] 1), prefabricated outsourcing steel frame 1 and water-intake steel grid 2;

[0030] 2) Concrete is poured at the original foundation position of the underwater water intake head to form the lower foundation 7 of the new roof, and the connecting bolts 6 are pre-embedded in the lower foundation 7;

[0031] 3), transport th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com