H-shaped steel beam and H-shaped steel column strong-axis variable-beam height fabricated node and construction method thereof

An H-beam, prefabricated technology, applied in construction, building structure, building material processing, etc., can solve the problems of poor adaptability to changes, difficult construction, low joint stiffness, etc., to achieve fast connection speed and reduce construction costs. The effect of difficulty and joint stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Examples see Figure 1-7 As shown, this H-shaped steel beam and H-shaped steel column strong axis variable beam height assembled joint includes H-shaped steel column 1 and H-shaped steel beam 2, and the node also includes T-shaped connector 3 and L-shaped connector 4 and bolts;

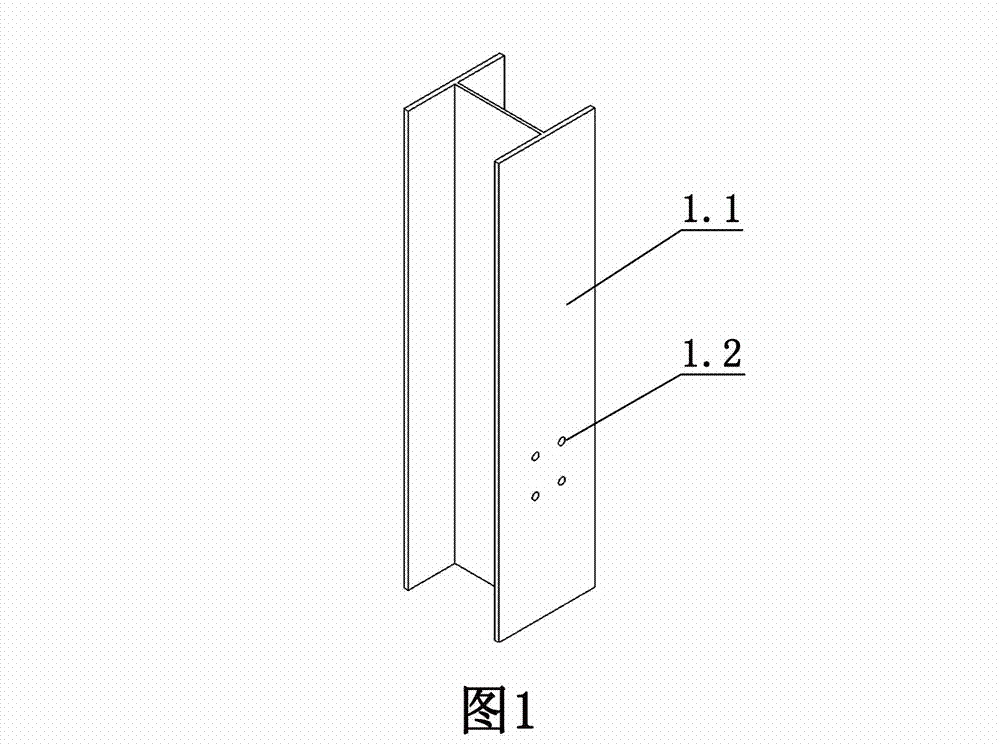

[0037] see figure 1 As shown, the column flange plate 1.1 of the H-shaped steel column 1 has reserved bolt holes 1.2 at the nodes. The number of reserved bolt holes 1.2 is four, distributed in a rectangular shape.

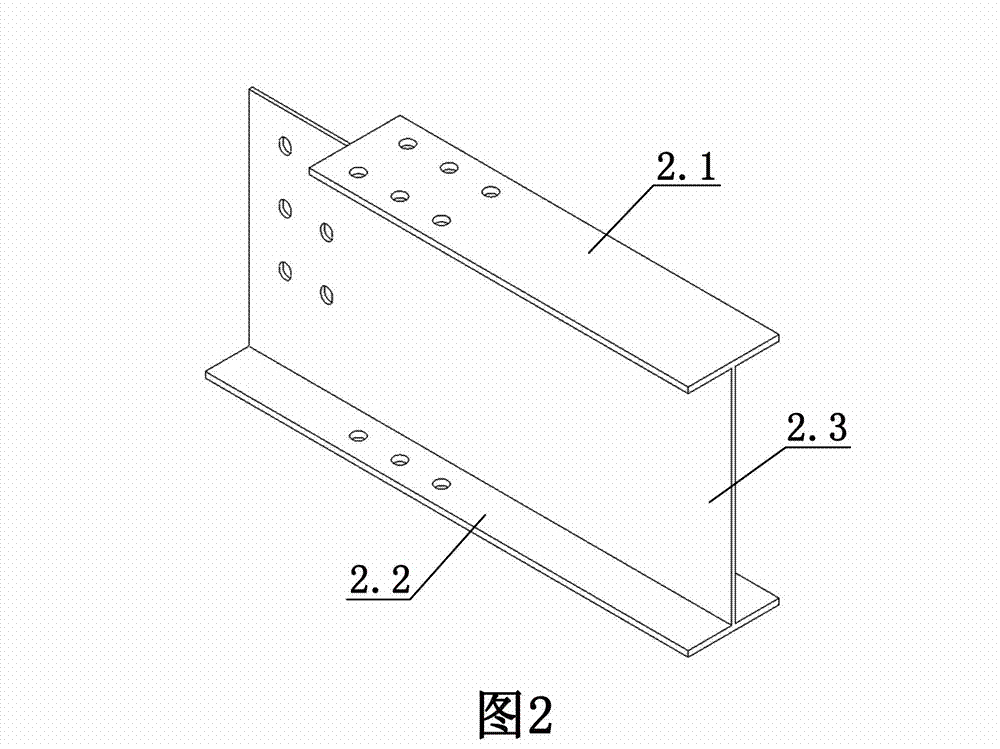

[0038] see figure 2 As shown, the upper flange plate 2.1, the lower flange plate 2.2 and the web plate 2.3 of the H-shaped steel beam 2 all have bolt holes at the nodes. The number of bolt holes is six. The upper flange plate 2.1 is partially cut off at the node, and the length of the cut section 2.4 is equal to the width of the web connection plate 3.2 of the T-shaped connector 3 .

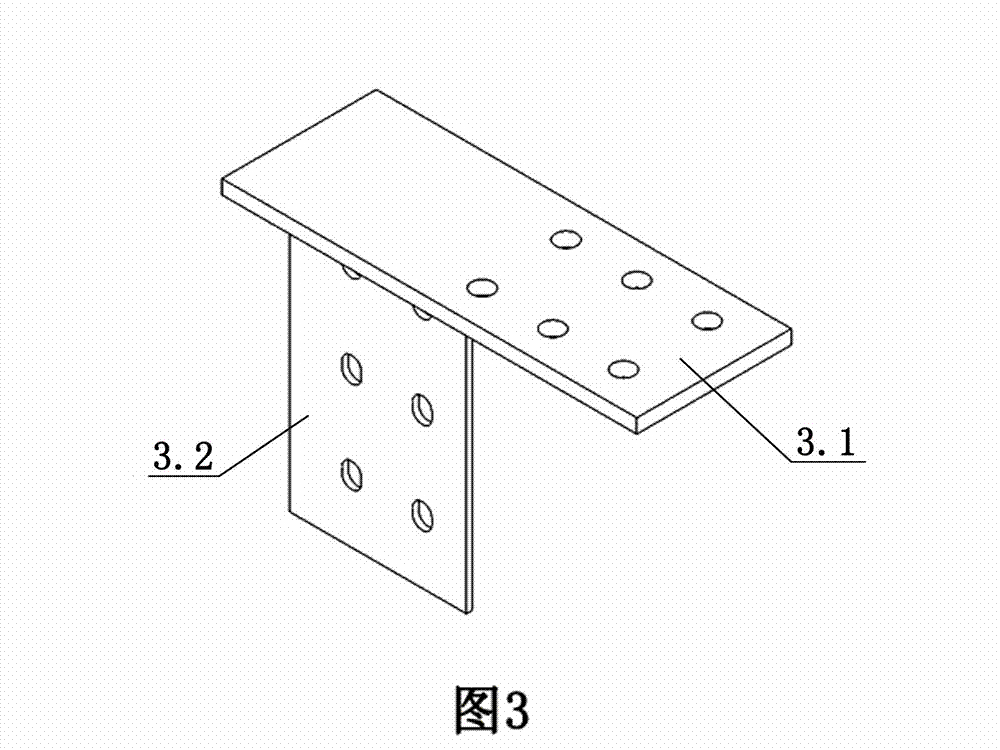

[0039] see image 3 , Figure 5 , Figure 6 As shown, the T-shaped connector 3 is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com