Partially prefabricated ground connection wall guide wall under underground facilities and construction method

A technology for underground facilities and ground-to-ground walls, which is applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems that reinforced concrete guide walls cannot be constructed, and the construction of ground-to-ground walls is difficult, and achieves simple construction and fast connection speed. , the effect of large node stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

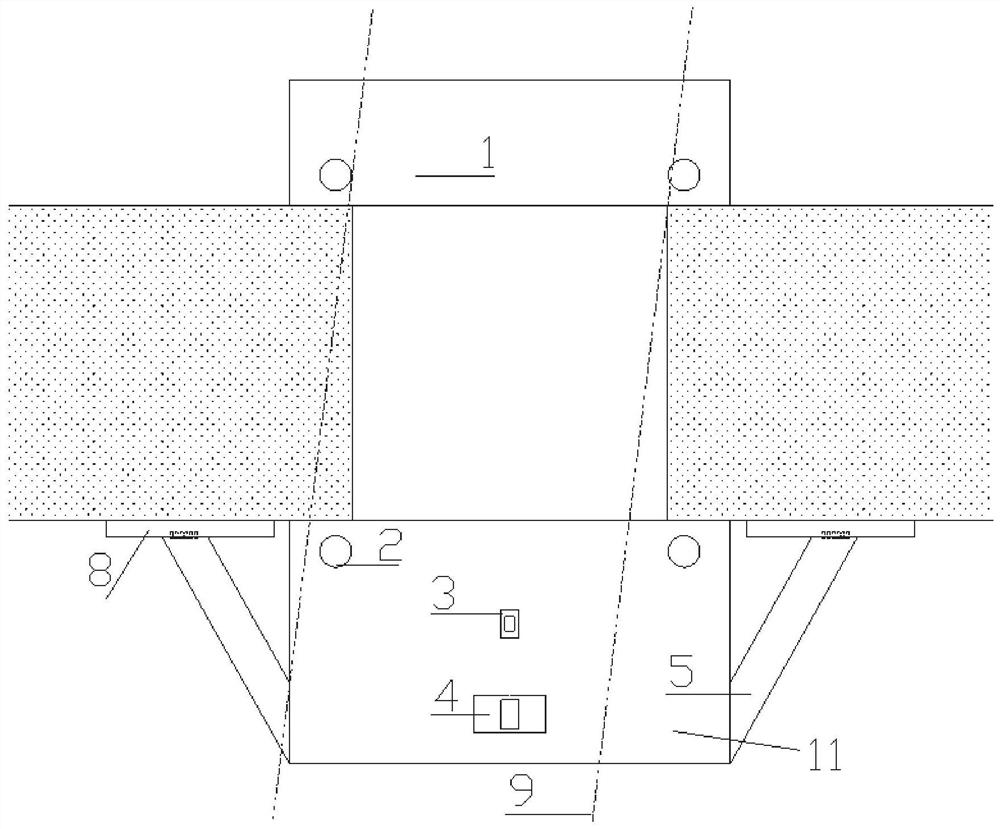

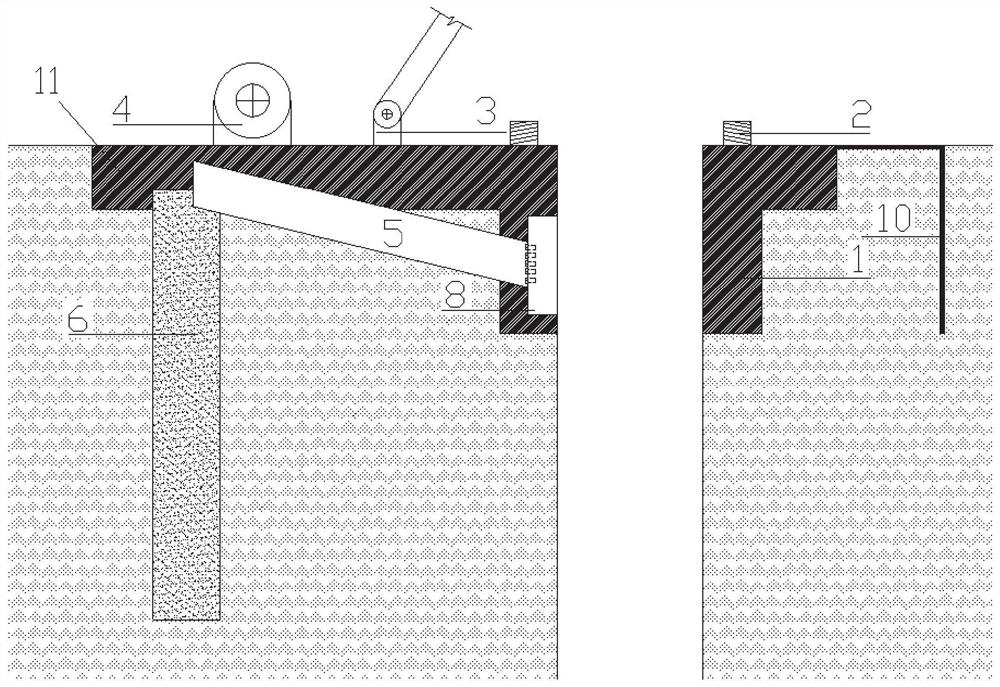

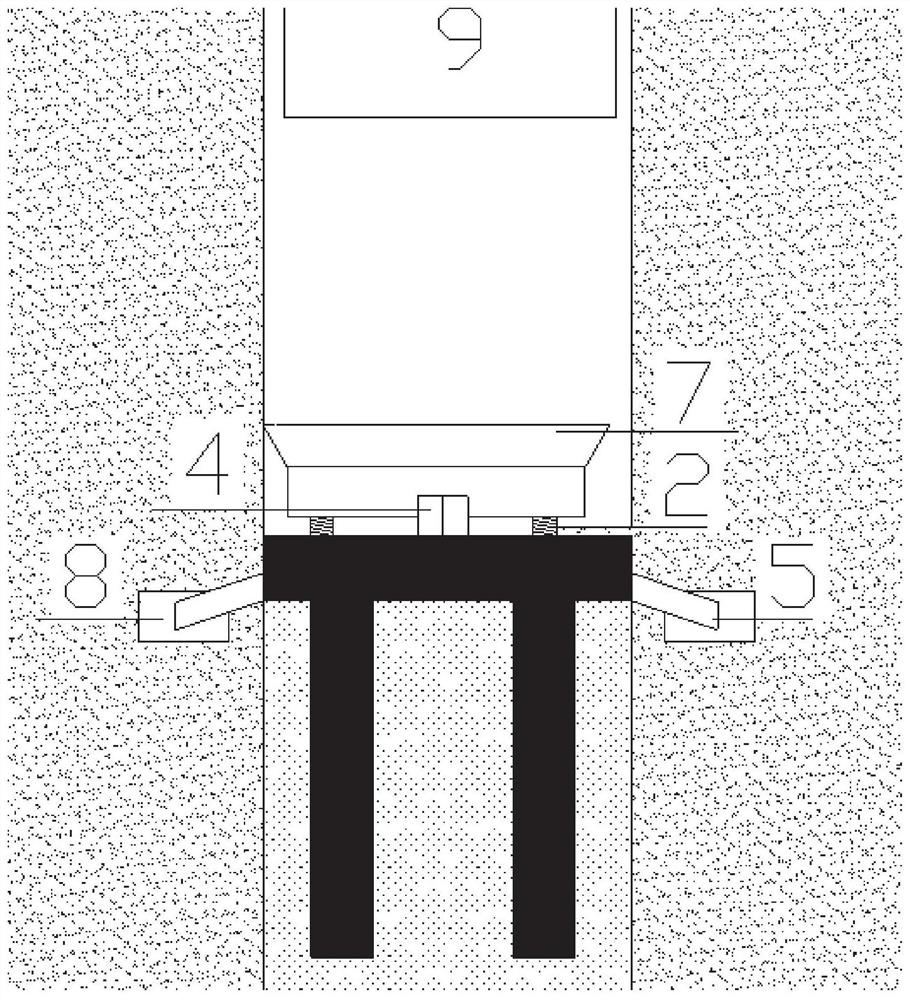

[0034] This embodiment provides a partially prefabricated ground connecting wall guide wall under the underground facility, which is arranged below the cable trench 9, and the trench is constructed below the cable trench 9. The cable trench 9 is used as an obstacle and needs to be dragged by underpinning. Such as figure 1 with figure 2 As shown, it includes a first guide wall 1 and a second guide wall 11 that are oppositely arranged, and the first guide wall 1 and the second guide wall 11 are respectively arranged on both sides of the trench.

[0035] One end of the second guide wall 11 is connected to the surrounding purlin 8, and the other end is connected to a plurality of uplift piles 6, and the uplift piles 6 are arranged vertically along the interior of the soil. Further, the uplift pile 6 is a reinforced concrete uplift pile. The pullout pile 6 is connected to the purlin 8 through the pullout pipe 5, and the pullout pipe 5 is steel.

[0036] Such as figure 2 with ...

Embodiment 2

[0045] This embodiment provides a construction method for partially prefabricated ground connecting walls and guide walls under underground facilities, which is constructed below the cable trench 9, including:

[0046] Step 1: Preparatory work before installing the guide wall:

[0047] (1) Pre-buried the fence 8 during the construction of the ground connection wall, or installed the fence 8 on the existing ground connection wall 9 . The side of the purlin 8 is left with a connection node for connecting the pullout pipe 5, and this connection node provides a large pulling force for the second guide wall 11 and subsequent operations to ensure the safety of the second guide wall 11.

[0048] (2) The uplift pile 6 is constructed in the auxiliary foundation pit, and the main reinforcement is reserved on the ground surface to prepare for the connection of the second guide wall 11 in the later stage. Since the 6 pile tops of the uplift piles are located underground, and the constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com