A thin-layer culture polygeneration system

An aquaculture system and polyproduction technology, which is applied in the field of thin-layer aquaculture polyproduction system, can solve the problems of difficulty in realizing polyproduction, poor vertical mixing, and low space utilization rate, etc. Strength requirements, the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

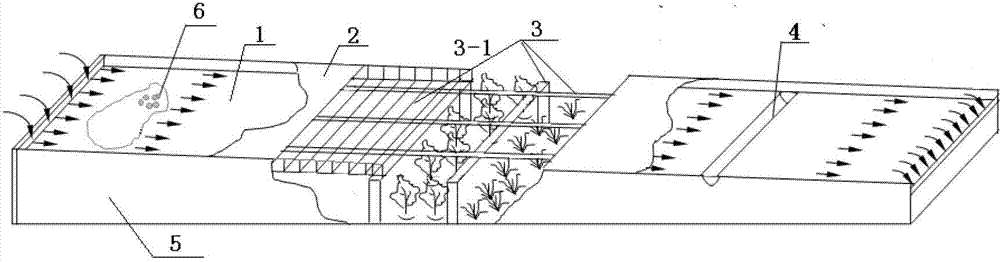

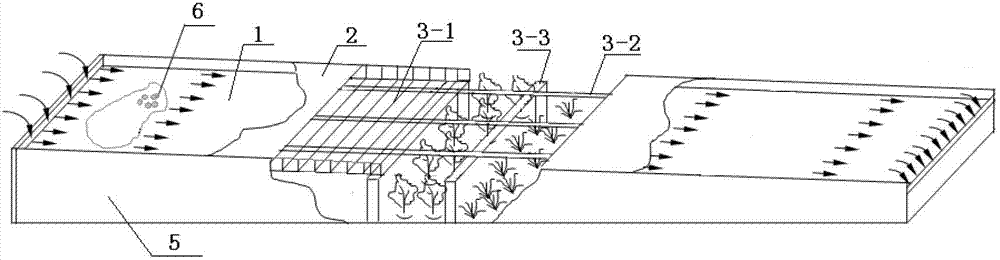

Embodiment 1

[0077] Such as image 3 As shown, in this embodiment, the bottom surface 1 is made of EVA shed film, which is attached to the first support beam 3-1 and tightened to form the cultivation device. The bottom surface 1 is rectangular, with a total length of 50 meters and a width of 10 meters. It is arranged obliquely along the supporting frame 3, and its high end is 3 meters away from the ground, and its low end is 2 meters away from the ground. The first support beam 3-1 is laid along the short side of the bottom surface 1 (that is, laid horizontally, perpendicular to the flow direction of the algae liquid), with a distance of 0.5 meters. The longitudinal load-bearing beam 3-2 is located under the first support beam 3-1 and along the bottom surface 1. Lay in the long side direction (that is, lay vertically, parallel to the flow direction of the algae liquid), with a spacing of 2.5 meters; set up 3-3 door-shaped supports at the bottom, with a spacing of 10 meters. The door supp...

Embodiment 2

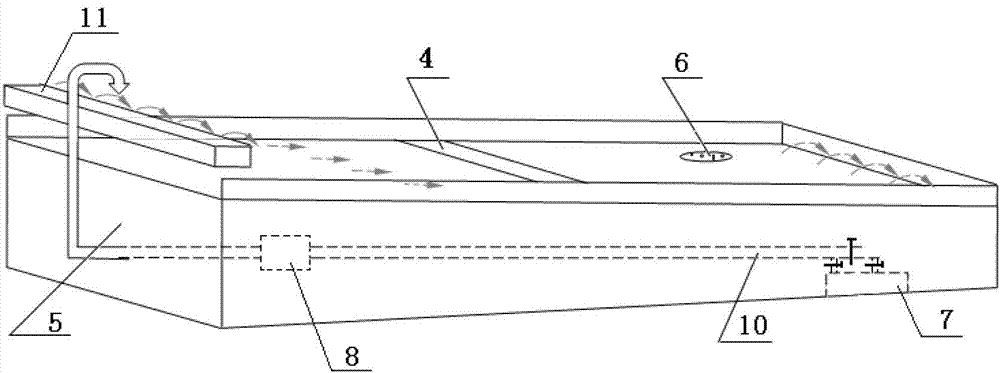

[0082] Such as Figure 4 As shown, in this embodiment, the bottom surface 1 is made of EVA shed film and is rectangular in shape with a total length of 100 meters and a width of 20 meters. In the middle of the bottom surface 1 (at 50 meters), there is an air replenishment tank 4 (10cm deep), and a microporous air replenishment pipe is set in the air replenishment tank 4, which is continuously fed with CO 2 For the gas of the component, the longitudinal load beam 3-2 at 4 places of the gas supply tank is disconnected. The high end of bottom surface 1 is 3.5 meters away from the ground, and the low end is 2 meters away from the ground. With the gas-liquid mixing pump as the power input device, the main valve is opened, the branch valve connected to the buffer tank 7 is closed, and the CO 2 Mixed gas with air (where CO 2 Concentration is 3%) fully contact with the algae liquid at the gas-liquid mixing pump to provide carbon source for the growth of microalgae. Cover film 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com