Three-dimensional packaging structure and method

A packaging structure, three-dimensional technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problem of inability to realize three-dimensional packaging, face-to-face sensing or detection of upper and lower chips, lack of internal cavity and three-dimensional Three-dimensional requirements and other issues to achieve the effect of preventing damage to the chip structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

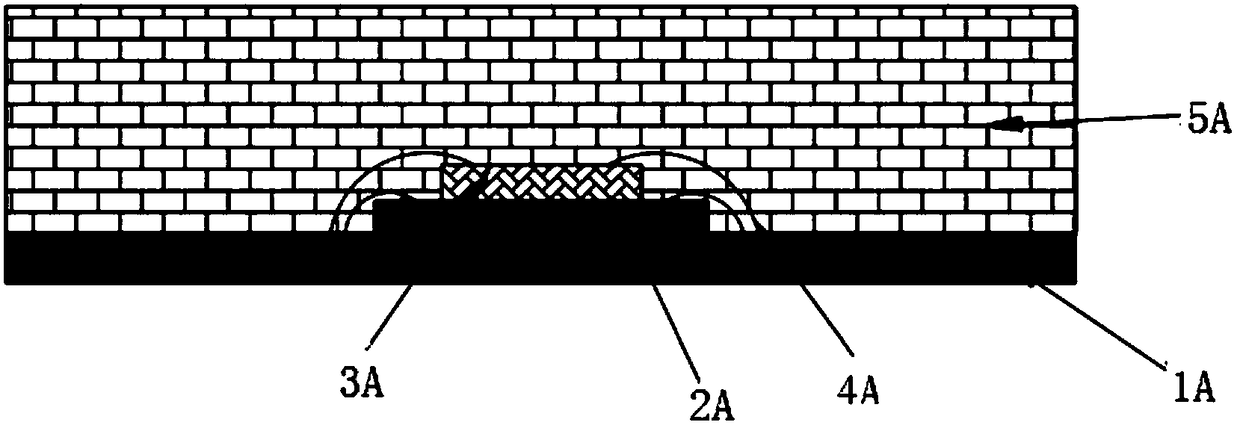

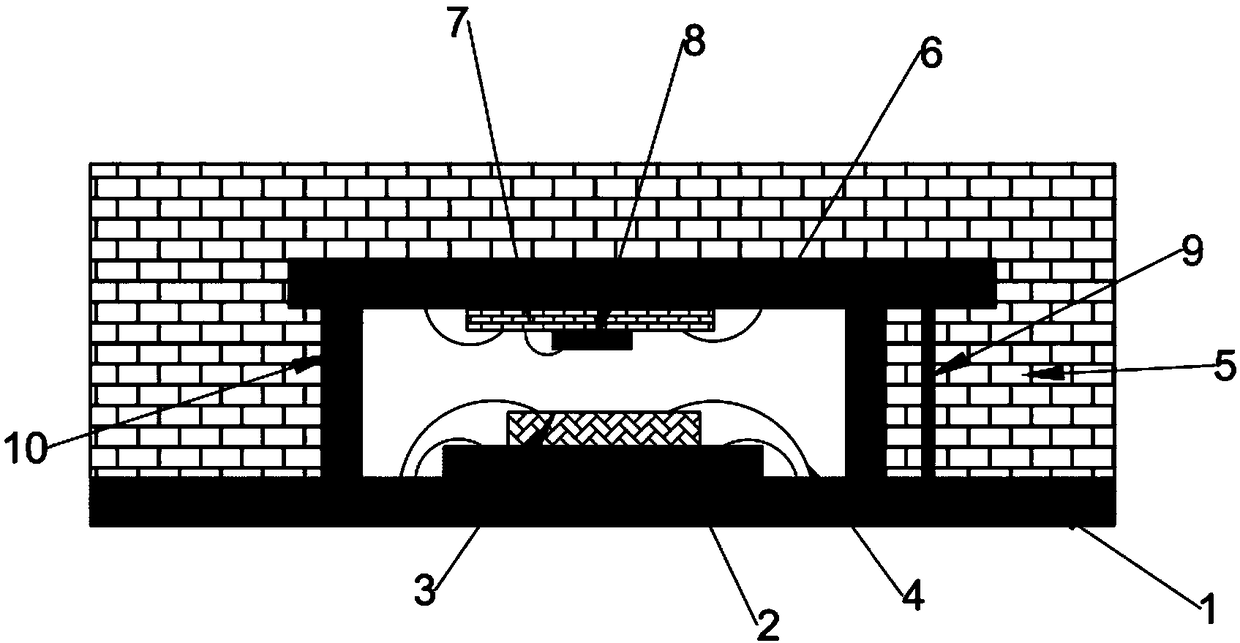

[0031] Example 1, such as figure 2 As shown, the present application provides a three-dimensional packaging structure, including an upper board 6 and a lower board 1, the upper board 6 and the lower board 1 are fixedly connected through a cavity support structure 10, and the cavity support structure 10 An installation space is formed between the upper board 6 and the lower board 1;

[0032] Specifically, the size and shape of the cavity support structure 10 can be designed and processed according to the actual product information, and can be regular shapes such as rectangles and circles, or irregular shapes, and the height is determined by the chip devices mounted inside and the distance between devices Decide. The cavity support structure 10 can be glued to the upper board 6 and the lower board 1 , or can be assembled by soldering. According to different types of chips integrated in the cavity, the cavity supporting structure 10 may be made of different materials such as m...

Embodiment 2

[0041] Example 2, such as figure 2 As shown, the present application provides a packaging method for a three-dimensional packaging structure, comprising the following steps:

[0042] Step 1, mount the first chip 2 on the upper surface of the download board 1, mount the second chip 3 (MEMS chip) in micro-assembly, and connect the first chip 2, the second chip 3 and the download board 1 by wire bonding Electrical interconnection to complete the module structure of the download board 1;

[0043] Step 2, mount the third chip 7 and the fourth chip 8 (optical detection sensor chip) on the lower surface of the upper board 6, and electrically interconnect the third chip 7, the fourth chip 8 and the upper board 6 by wire bonding. Connect, complete the module structure of the upload board 6;

[0044] Step 3, assembling and installing the cavity supporting structure 10 on the assembled loading board 1 by gluing or metal welding;

[0045] Step 4, aligning and mounting the upper board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com