Connecting structure for prefabricated concrete wall and concrete edge columns and construction method

A prefabricated concrete and concrete wall technology, applied in the direction of columns, walls, pier columns, etc., can solve the problems of unreliable connection and low construction accuracy requirements, and achieve the effects of good integrity, reduced cast-in-place operations, and shortened time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

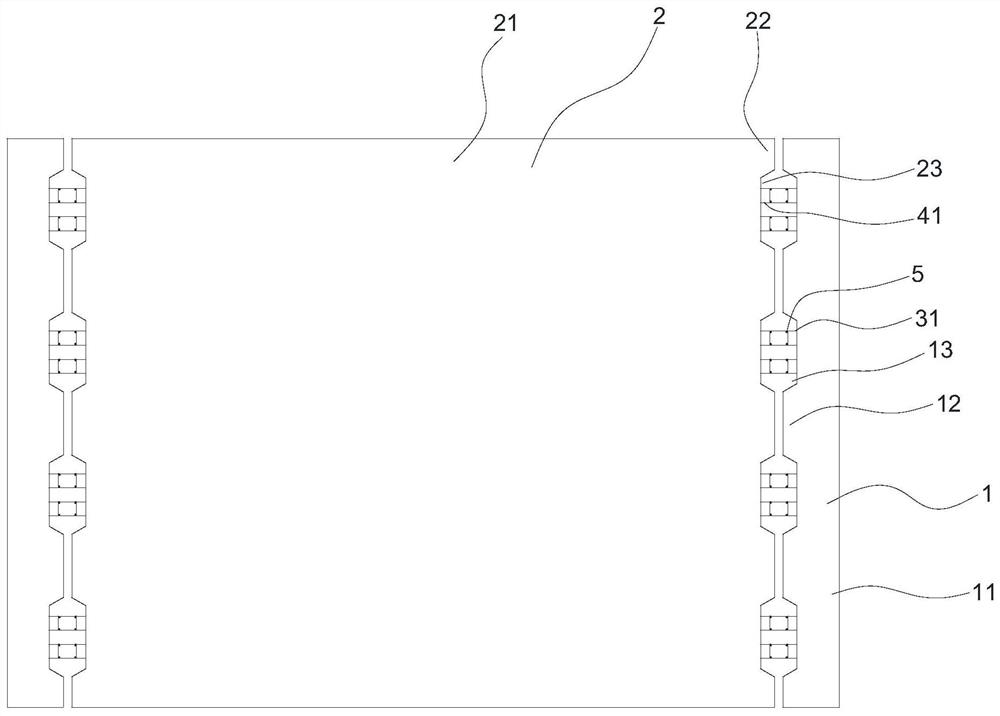

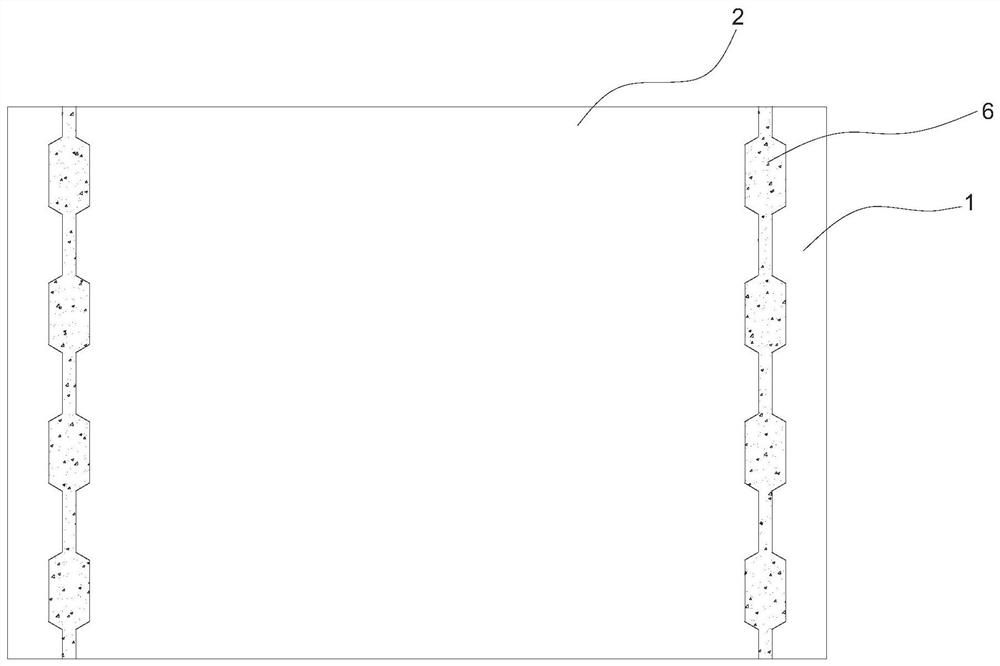

[0031] Such as figure 1 , figure 2 and image 3 As shown, this embodiment provides a connection structure between a prefabricated concrete wall and a concrete edge column, including a concrete edge column 1, a concrete wall 2, a first vertical stirrup 31, a second vertical stirrup 41 and a connecting stirrup 5.

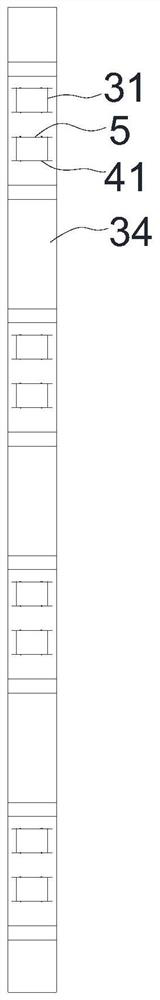

[0032] Such as figure 1 , Figure 4 and Figure 5 As shown, two concrete edge columns are located on both sides of the concrete wall. The concrete edge columns include a column body 11 and a first protrusion 12, and a plurality of first protrusions are arranged longitudinally at intervals on one side of the column body. There is a first groove 13 between the two first protrusions, and the first vertical stirrup is connected with the concrete edge column and is located in the first groove; the concrete edge column includes the edge column steel frame and is poured on the edge column steel frame concrete, the edge column reinforcement frame includes the first lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com