Glass pedal connecting device and its installation method

An installation method and pedal technology, applied in the direction of pedals, buildings, stairs, etc., can solve the problems of complex process and extremely high installation requirements, and achieve the effect of reducing construction accuracy requirements and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

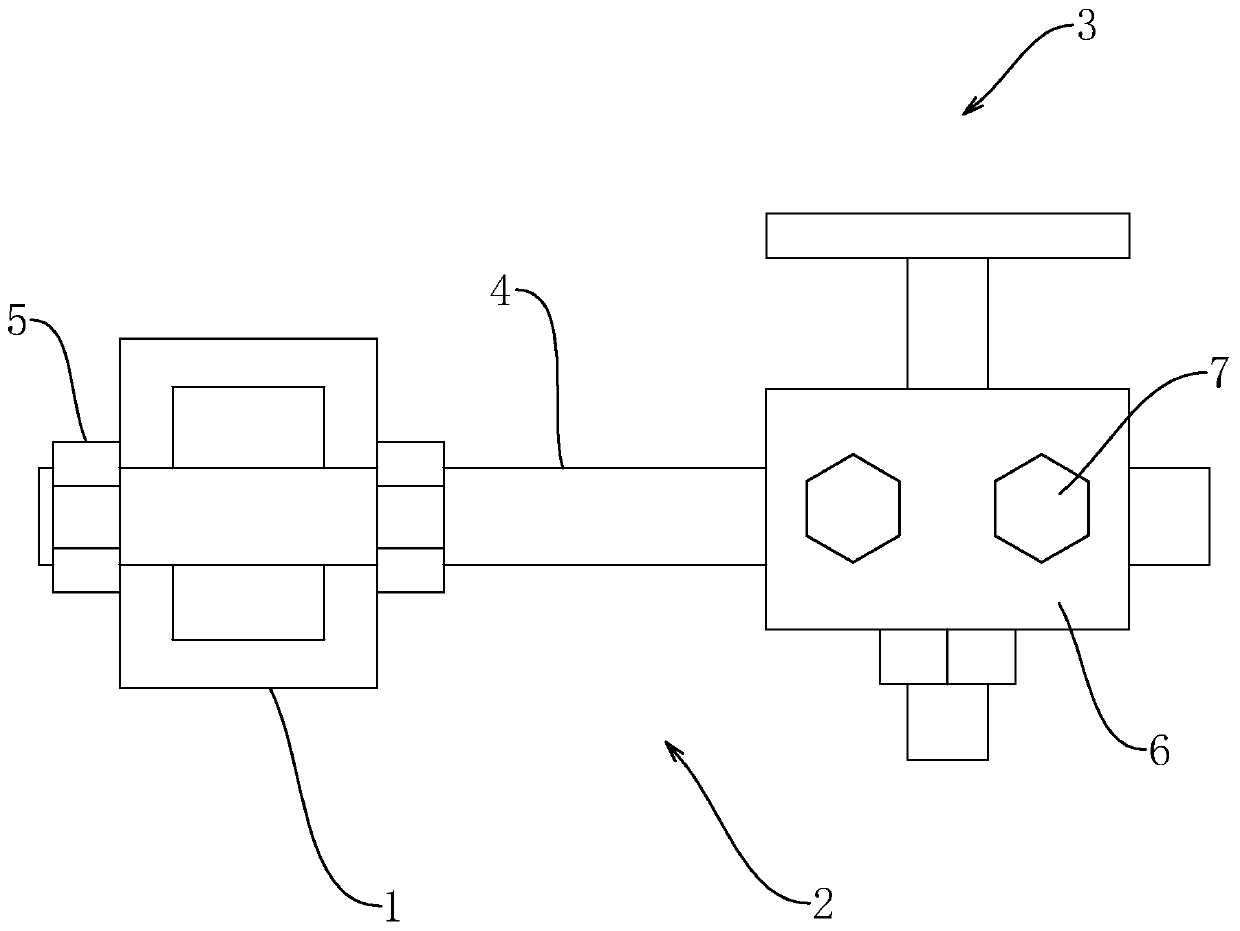

[0041] Such as figure 1 As shown, a glass pedal docking device includes a support frame 1, a movable frame 2 connected to the support frame 1, and a support member 3 connected to the upper end of the movable frame 2 and abutted against tempered glass.

[0042] Such as figure 1 As shown, the movable frame 2 includes two horizontal rods 4 parallel to and passing through the support frame 1, and the horizontal rods 4 are respectively threaded with first fixing nuts 5 at the two ends of the supporting frame 1, and are supported by the first fixing nuts 5. The two ends of frame 1 fix the position of horizontal bar 4. One end of the horizontal rod 4 away from the support frame 1 is slidably connected with a horizontal seat 6, and the side of the horizontal seat 6 is threadedly connected with a first adjusting bolt 7. The position is fixed.

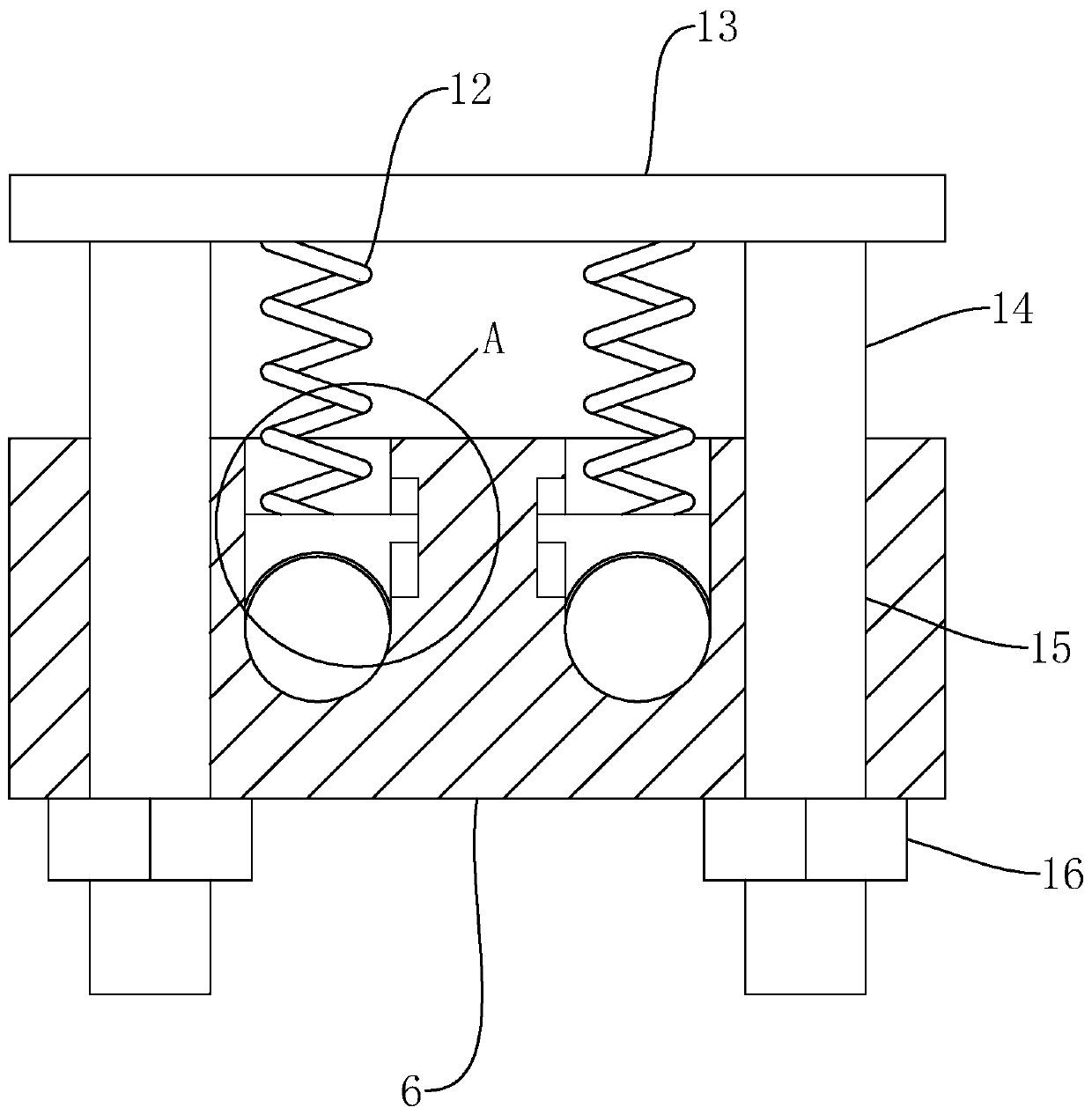

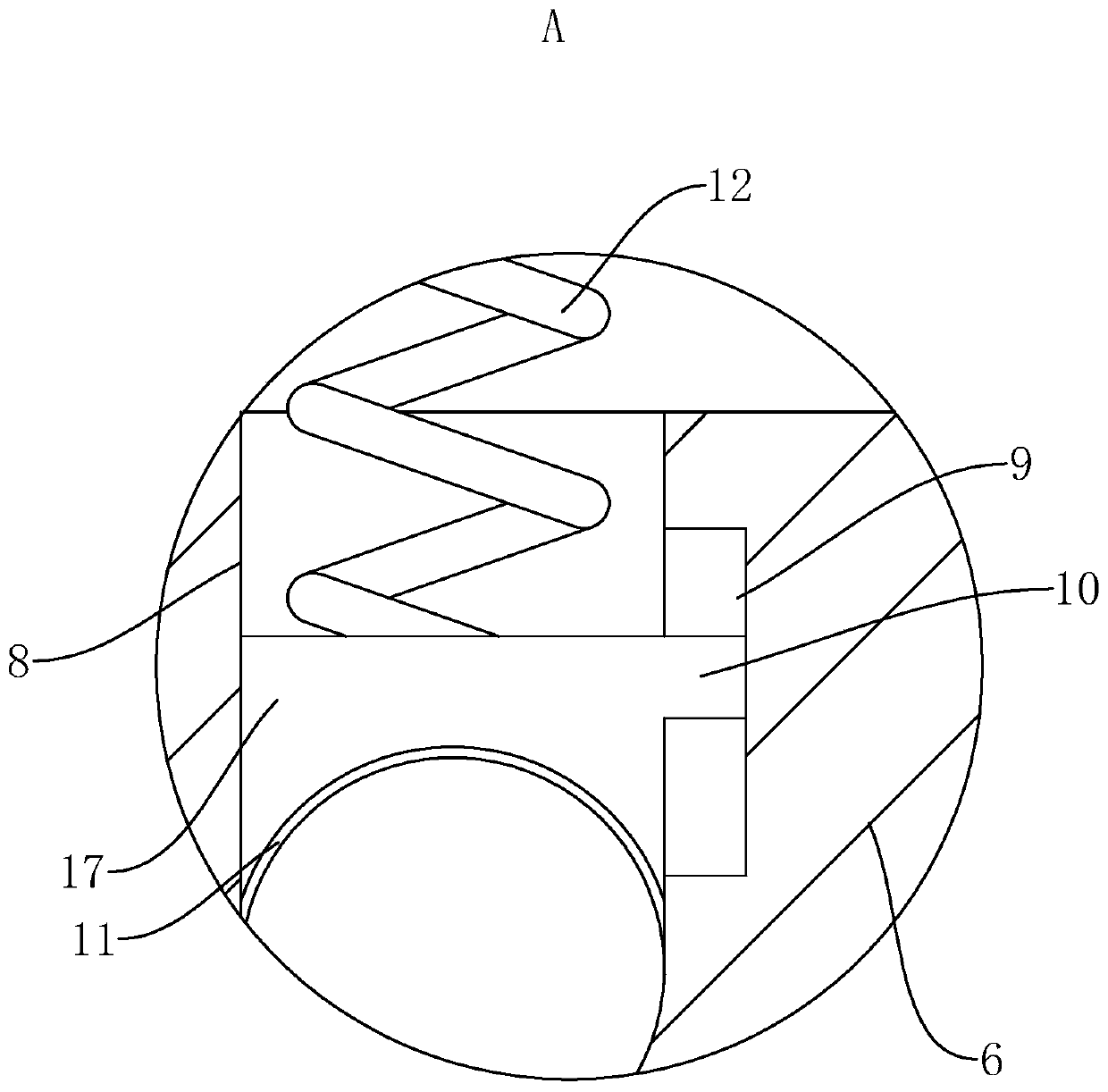

[0043] Such as figure 2 and image 3 As shown, the upper surface of the level seat 6 is respectively opened with a through hole 8 connect...

Embodiment 2

[0046] A method for installing a glass pedal, comprising:

[0047] Step 1, install the horizontal bar 4;

[0048] After screwing on a first fixing nut 5 on the horizontal bar 4, pass the threaded end of the horizontal bar 4 through the support frame 1 and then lock the horizontal bar 4 by the first fixing bolt, so that the horizontal bar 4 is fixed on the support frame 1 on.

[0049] Step 2, adjust the movable frame 2;

[0050] When adjusting the position of the level seat 6 to the set place, the position of the movable frame 2 is preliminarily fixed by tightening the first adjusting bolt 7 .

[0051] Step 3, initially extruding the stage clip 12;

[0052] Tighten the second adjusting nut 16 so that the compression spring 12 is squeezed and contracted. At this time, the compression amount of the compression spring 12 is less than the expected compression amount of the tempered glass installed. At this moment, under the pressure of the compression spring 12, the movable block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com