Foam interlayer structure compound material and preparation method thereof

A composite material and sandwich structure technology, applied in the field of foam composite materials, can solve problems such as insufficient strength, high resin content on the surface of laminates, damage, etc., and achieve the effect of improving shear stiffness, excellent mechanical strength, and broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

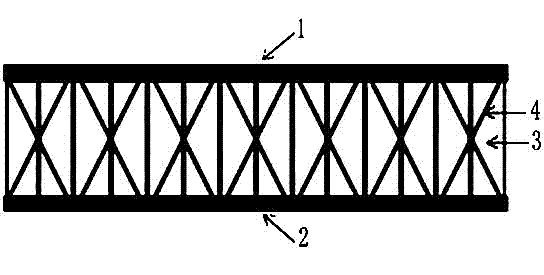

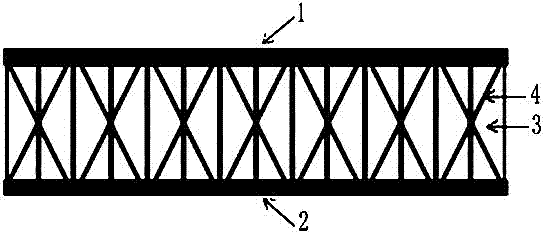

[0021] A foam sandwich structure composite material, see figure 1 , the composite material comprises an upper skin 1, a lower skin 2, a foam core 3 and a pultrusion rod 4, the foam core 3 is arranged between the upper skin 1 and the lower skin 2; One end of a set of pultrusion rods 4 is connected to the upper skin 1, and the other end is connected to the lower skin 2 to form a rice-shaped structure, and there is a connecting upper skin 1 and lower skin between two adjacent rice-shaped structures. 2 of the pultruded rod 4 .

[0022] A kind of its preparation method of foam sandwich structure composite material, comprises following operation:

[0023] The core material selection density is 50kg / m 3 The polymethacrylimide foam, on the special tooling, implants the pin into the foam core in a mixed manner perpendicular to the foam surface and at a certain angle to form a rice-shaped structure, and the implantation density of the pin perpendicular to the foam surface is 5mm× 5mm...

Embodiment 2

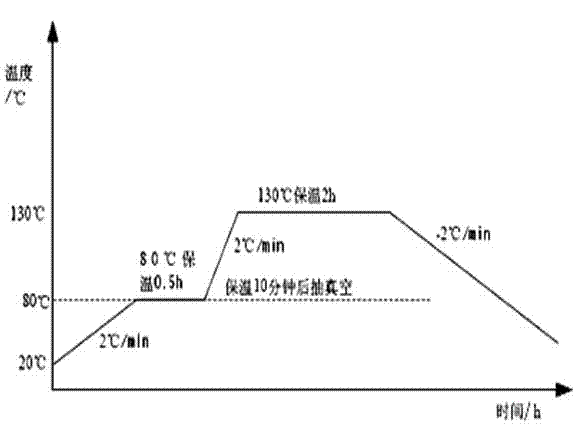

[0027] The core material selection density is 50kg / m 3 The polymethacrylimide foam, on the special tooling, the pin and the foam surface are at 45°, and the implantation density is 10mm×10mm. The upper and lower skins are made of glass fiber epoxy fabric prepreg with a single layer thickness of 0.15 mm, and a 3-layer layup is used. It is required that the pin should be embedded in the first layer of layup to ensure a good combination of pin and layup. The vacuum curing process is adopted, and the curing process curve is as follows: figure 2 . After curing and cooling down, the rice-shaped foam sandwich structure composite material is obtained. According to the principle of pin centering and symmetry, the sample size is selected as follows: flat compression sample is 60mm×65mm; shear sample is 60mm×285mm; bending sample It is 60mm×285mm.

[0028] After testing, the compressive modulus is 65.6MPa; the shear strength is 6.87MPa; the bending strength is 255Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com