Pouring mold and pouring method for gypsum shield segment model

A technology for shielding segments and pouring molds, which is applied to molds, reinforcement molding, ceramic molding cores, etc., can solve the problems of large deviation of simulated structure, obtained structural mechanical behavior results, rough gypsum model, etc., and achieves feasible operation and test results. Authentic, well-structured results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

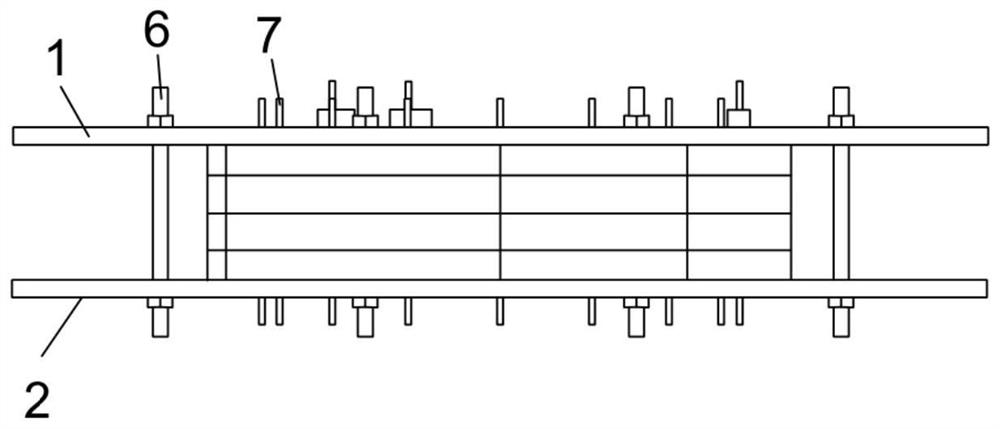

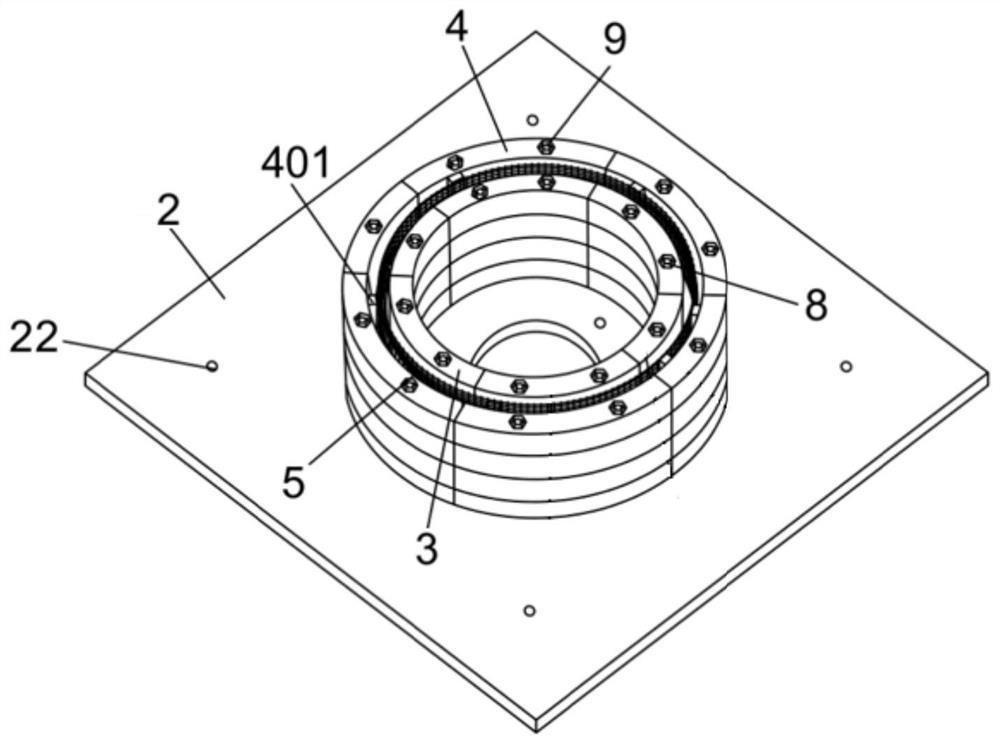

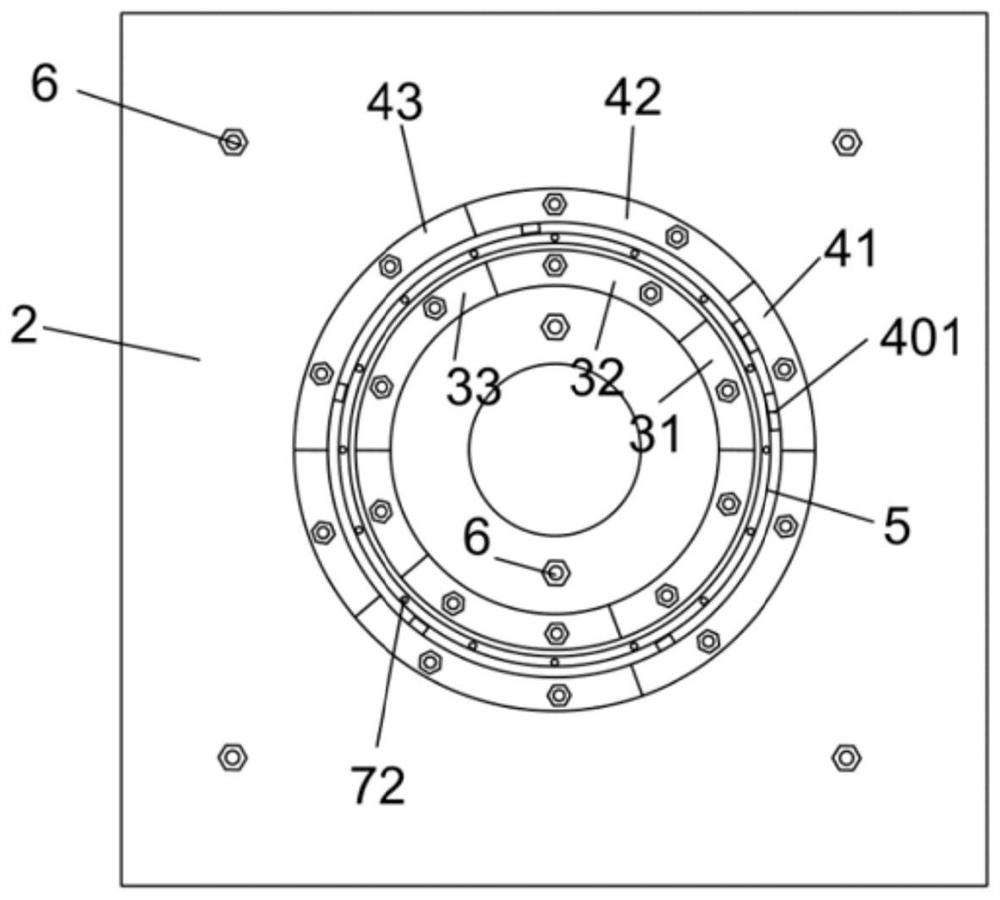

[0065] as attached Figure 1-12 As shown, the present embodiment provides a casting mold for a gypsum shield segment model, including an upper cover plate 1, a lower cover plate 2, an inner mold 3, an outer mold 4, annular reinforcement 5, cover plate fixing bolts 6 and several Positioning rod 7; the upper cover 1 and the lower cover 2 are arranged parallel up and down, the inner mold 3 and the outer mold 4 are vertically fixed between the upper cover 1 and the lower cover 2, and the outer mold 4 is set in the inner mold 3 The outer side of the inner mold 3 and the outer mold 4 are arranged at intervals; a gypsum pouring area is formed between the inner mold 3 and the outer mold 4.

[0066] The upper cover plate 1 is provided with a number of positioning rod upper fixing holes 11, upper cover plate fixing bolt holes 12, upper cover plate inner mold bayonet 13, upper cover plate outer mold bayonet 14, vent hole 15 and vent hole closure Body 16; the lower cover 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com