Method for operating a measuring device and measuring device

A technology for measuring devices and measuring directions, applied in measuring devices, measuring flow/mass flow, fluid velocity measurement, etc., can solve problems such as increasing measurement data evaluation computing power, and achieve the effect of fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

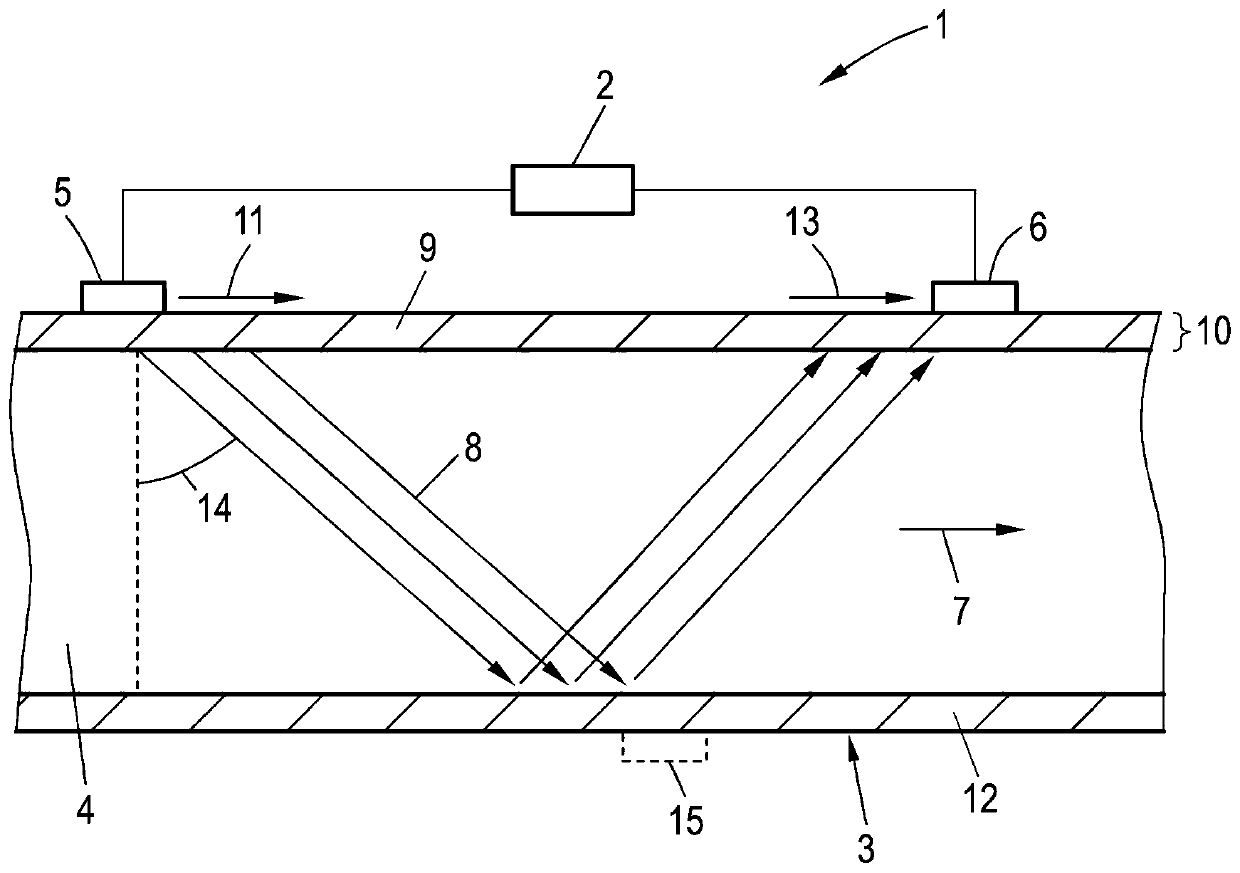

[0038] figure 1Shown is a measuring device 1 for determining a fluid quantity, in particular a flow rate, in relation to a fluid and / or a fluid flow. As will be explained in more detail below, the measuring device 1 is also adapted to determine resulting information about the fluid itself and / or the state of the measuring device 1 . The fluid is conveyed in the direction indicated by the arrow 7 through the interior 4 of the measuring tube 3 . In order to determine the fluid quantity, in particular the flow rate, the time-of-flight from the first oscillating transducer 5 to the second oscillating transducer 6 and from the second oscillating transducer 6 to the first oscillating transducer can be determined by the control device 2 The flight time difference between the flight times of 5. In this case, use is made of the fact that this time-of-flight depends on the velocity component of the fluid parallel to the direction of propagation of the ultrasound beam 8 through the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com