Ash smearing device and construction method in large-area ground flatness control of ash smearing device

A technology of ground and ash cake, applied in the direction of construction and building structure, can solve the problems such as the inability to meet the flatness requirements of large-area ground, and achieve the effect of excellent apparent quality, speeding up construction, and meeting the requirements of specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

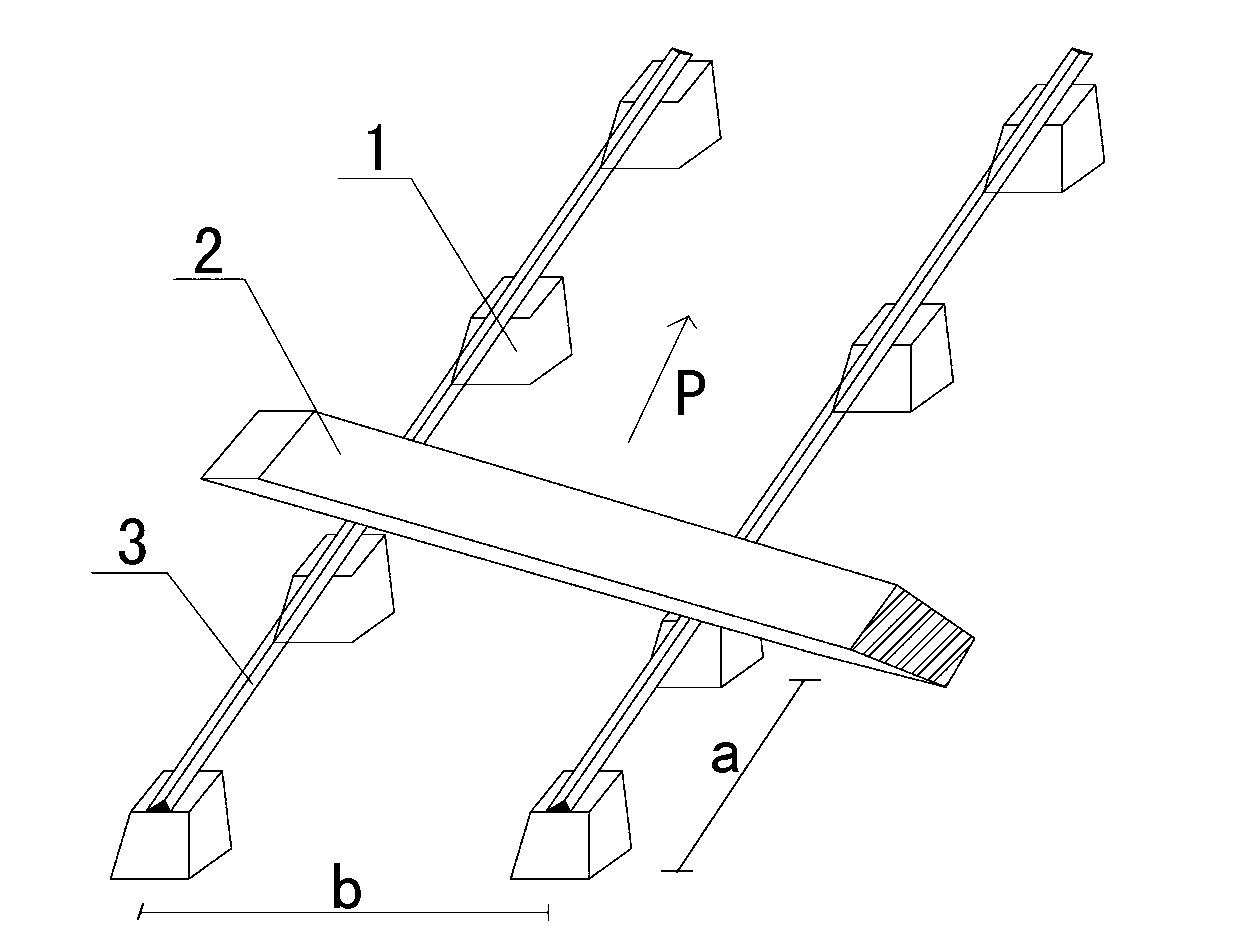

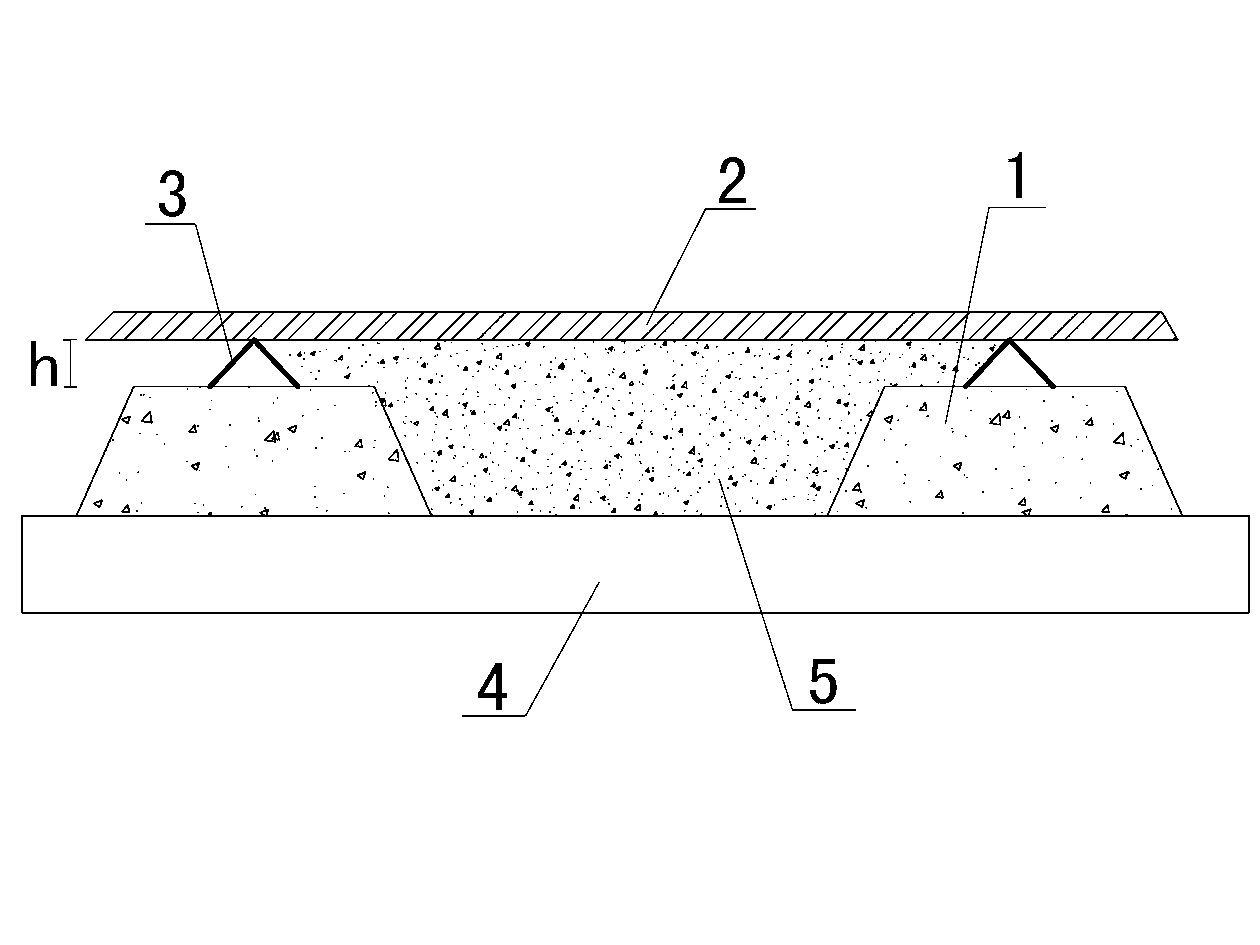

[0028] Examples see Figure 1-2 As shown, a plastering device includes an ash cake 1 and a scraper bar 2, the ash cake 1 is symmetrically arranged on the ground base 4 on the left and right sides of the ground to be poured 5, and the ash cake on the left and right sides of the ground to be poured 5 A plurality of them are provided at intervals along the concrete pouring direction P, and the ash cake on the left side of the ground 5 to be poured and the ash cake on the right side of the ground 5 to be poured are respectively buckled and placed (that is, the angle steel is placed on the ash cake through the tips of the two limbs). There is an angle steel guide rail 3 on the cake (the back of the limb of the angle steel faces upwards), and the scraper bar 2 is slidably placed between the two angle steel guide rails 3 .

[0029] The distance a between the ash cakes on the left and right sides of the ground to be poured is not greater than 1500mm along the direction of concrete pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com