Manufacturing process of streetcar rail plate

A technology for trams and manufacturing processes, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of difficulty in ensuring the assembly accuracy of track plates, high requirements for the size of embedded track-bearing grooves, and difficulties in the production and manufacture of track plates. Assembly, easy demoulding, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

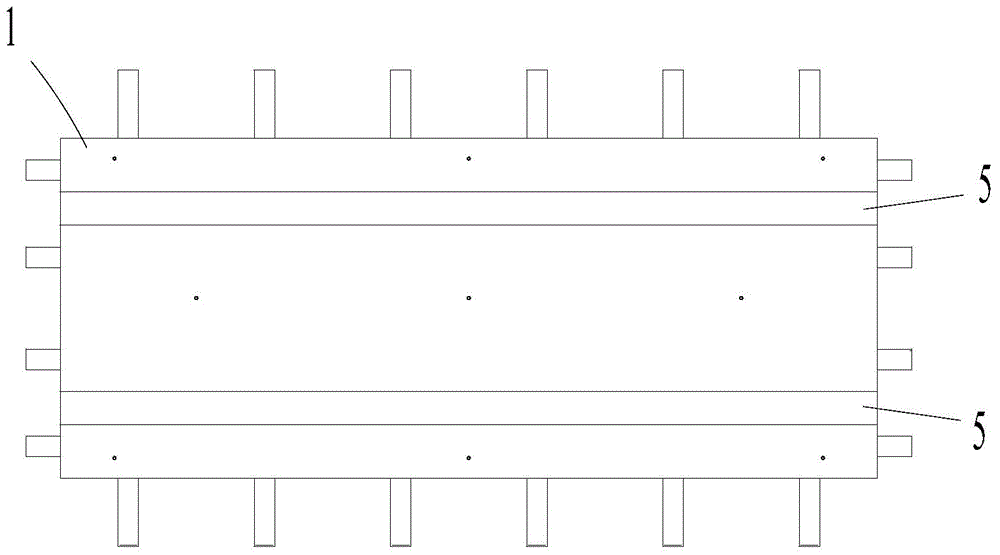

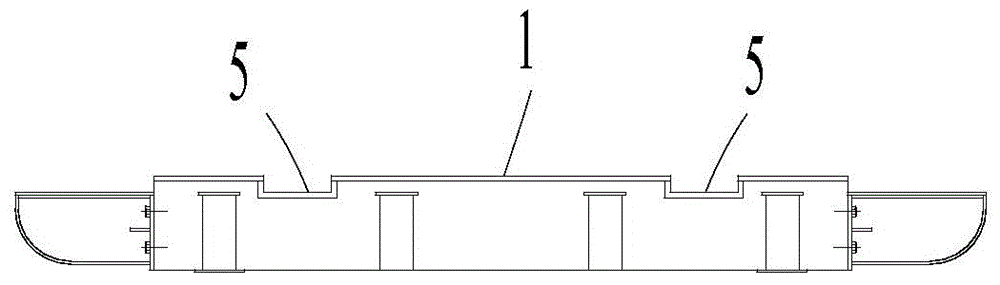

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

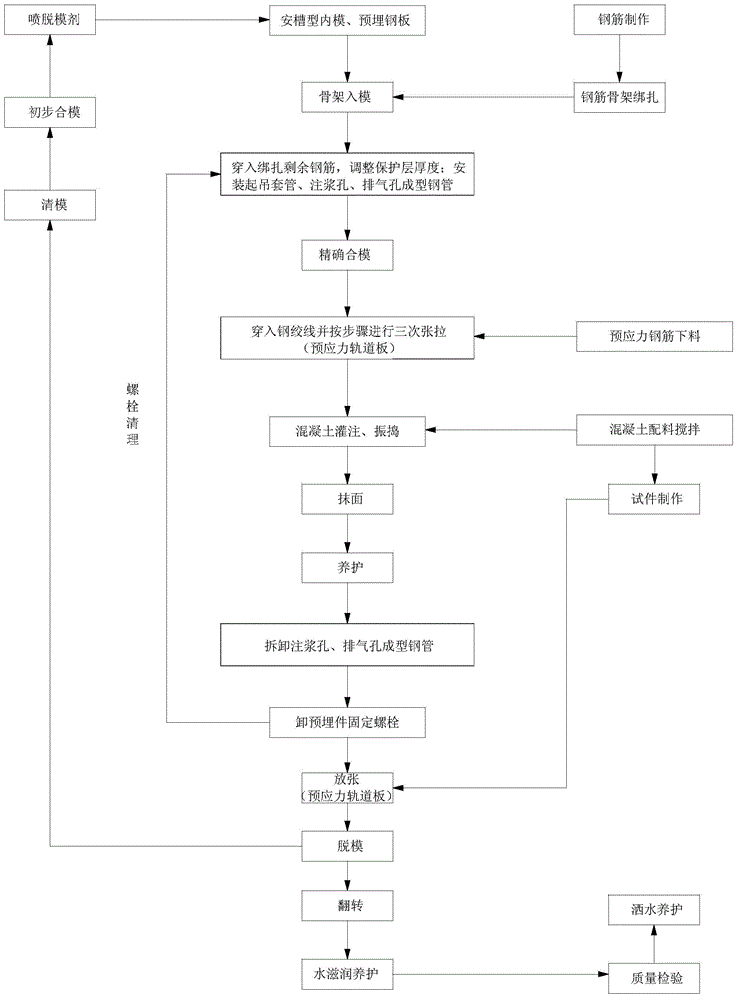

[0030] Tram track slab manufacturing process, such as figure 1 As shown, including the following process flow:

[0031] Mold cleaning→mold closing→spraying release agent→installing pre-embedded steel plate→reinforcement skeleton into the mold→adjusting the thickness of the protective layer→penetrating steel strands and stretching→concrete pouring, vibrating, plastering→maintenance→remove the grouting hole mold , Vent hole mold, pre-embedded fixing bolts → release → demoulding → quality inspection → water moisturizing maintenance, specifically include the following steps:

[0032] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com