Titanium and titanium alloy short-process preparation device and method

A preparation device and a technology for titanium alloys, which are applied in the field of titanium and titanium alloy short-flow preparation devices, can solve the problems of inability to eliminate high and low density inclusions, narrow smelting application range, complex processing technology, etc., so as to improve melting effect and preparation The effect of improving efficiency and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

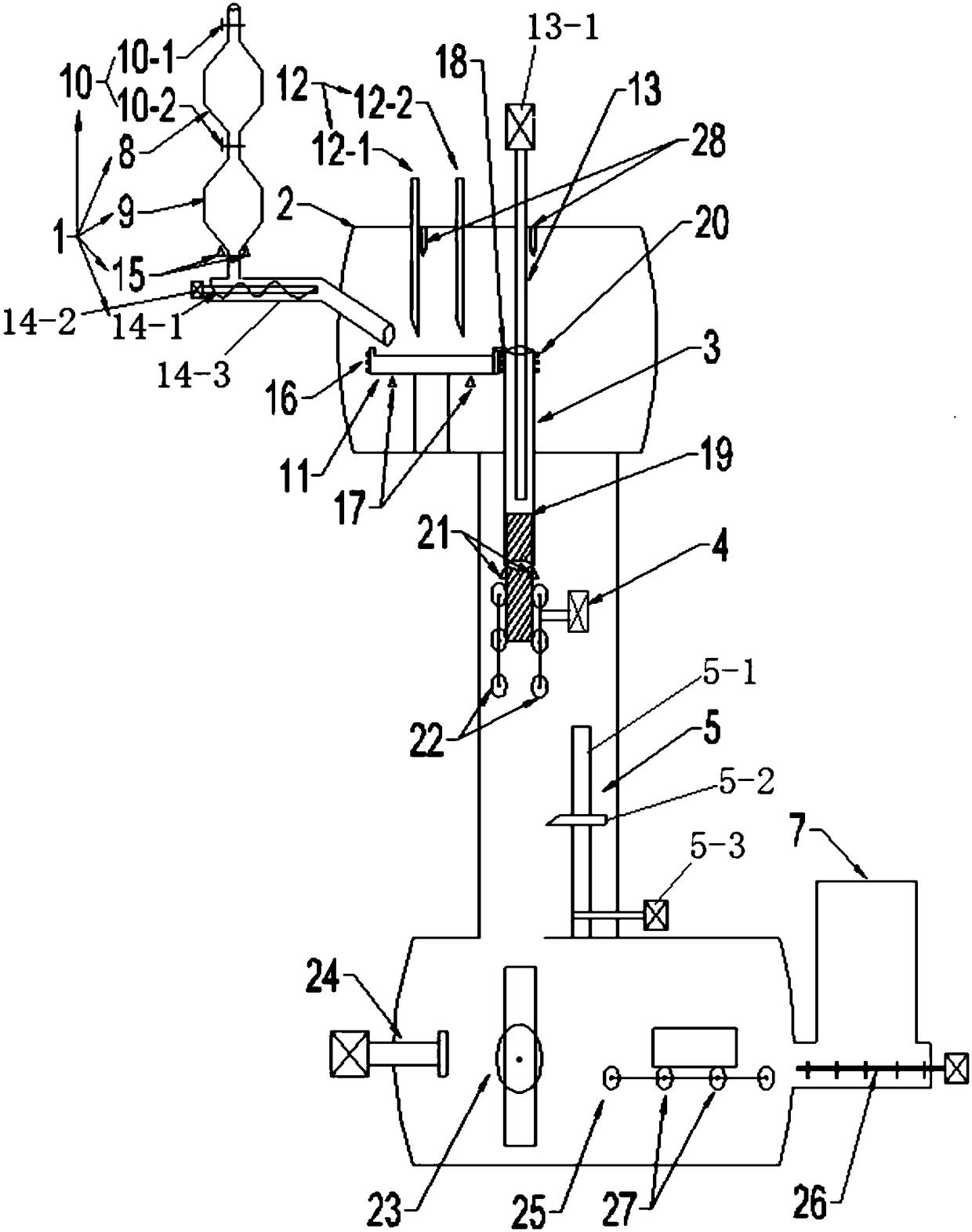

[0068] Based on the above figure 1 The short-process preparation method for preparing titanium and titanium alloys with advanced preparation equipment generally includes continuous feeding, alloy smelting, solidification and down-drawing, fixed-length cutting, finished product turning and conveying processes, and realizes the preparation process of one-time cooling bed smelting and forming.

[0069] combine figure 1 The preparation device shown, the process of the short-flow preparation method of titanium and titanium alloys will be described in more detail below.

[0070] Step 1. Continuous feeding: Add the raw material (sponge titanium or the mixture of sponge titanium and intermediate alloy) into the upper silo 8, close the first and second vacuum slide valves 10-1 and 10-2, and then pump the material through the vacuum pump. Vacuum, open the second vacuum slide valve 10-2 after the vacuum value reaches the set value, the vacuum value range is ≤5Pa, the raw material enters...

Embodiment 1

[0089] This embodiment provides a short-process preparation method for titanium and titanium alloys, including the following steps:

[0090] a. Continuous feeding: Put 120kg of titanium sponge into the feeding mechanism and then vacuumize to 3pa, then add the raw materials to the 1.1atm argon-filled protective atmosphere device, and then put 120kg of titanium sponge into the feeding mechanism to achieve continuous feeding; Transport the titanium sponge in the feeding mechanism to the water-cooled copper hearth in the raw material smelting chamber;

[0091] b. Alloy smelting: When the amount of sponge titanium in the water-cooled copper hearth reaches a certain level, the smelting plasma gun starts to generate plasma arc spots to melt the sponge titanium. When the pure titanium liquid flows under the refining plasma gun to form a condensed shell, the refining plasma gun starts Refining pure titanium liquid;

[0092] c. Solidification pull-down: When the liquid level of pure ti...

Embodiment 2

[0101] This embodiment provides a short-process preparation method for titanium and titanium alloys, including the following steps:

[0102] a. Continuous feeding: Put 120kg of titanium sponge into the feeding mechanism and vacuumize to 2pa, then add the raw materials into the 1.1atm argon-filled protective atmosphere device, and then put 120kg of premixed material into the feeding mechanism to achieve continuous feeding ;Transfer the titanium sponge in the feeding mechanism to the water-cooled copper hearth in the raw material smelting chamber;

[0103] b. Alloy smelting: When the amount of sponge titanium in the water-cooled copper hearth reaches a certain level, the smelting plasma gun is started to generate a plasma arc spot to melt the premixed material. When the pure titanium liquid flows under the refining plasma gun to form a condensed shell, the plasma gun is refined Start refining pure titanium liquid;

[0104] c. Solidification and pull-down: When the liquid level ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com