Manufacturing method of plastic fuel tank

A manufacturing method and fuel tank technology are applied in the manufacturing field of plastic fuel tanks, which can solve the problems of low production efficiency of single-station blow molding machines, reduce investment in tooling equipment and production space, reduce energy consumption, and improve drying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

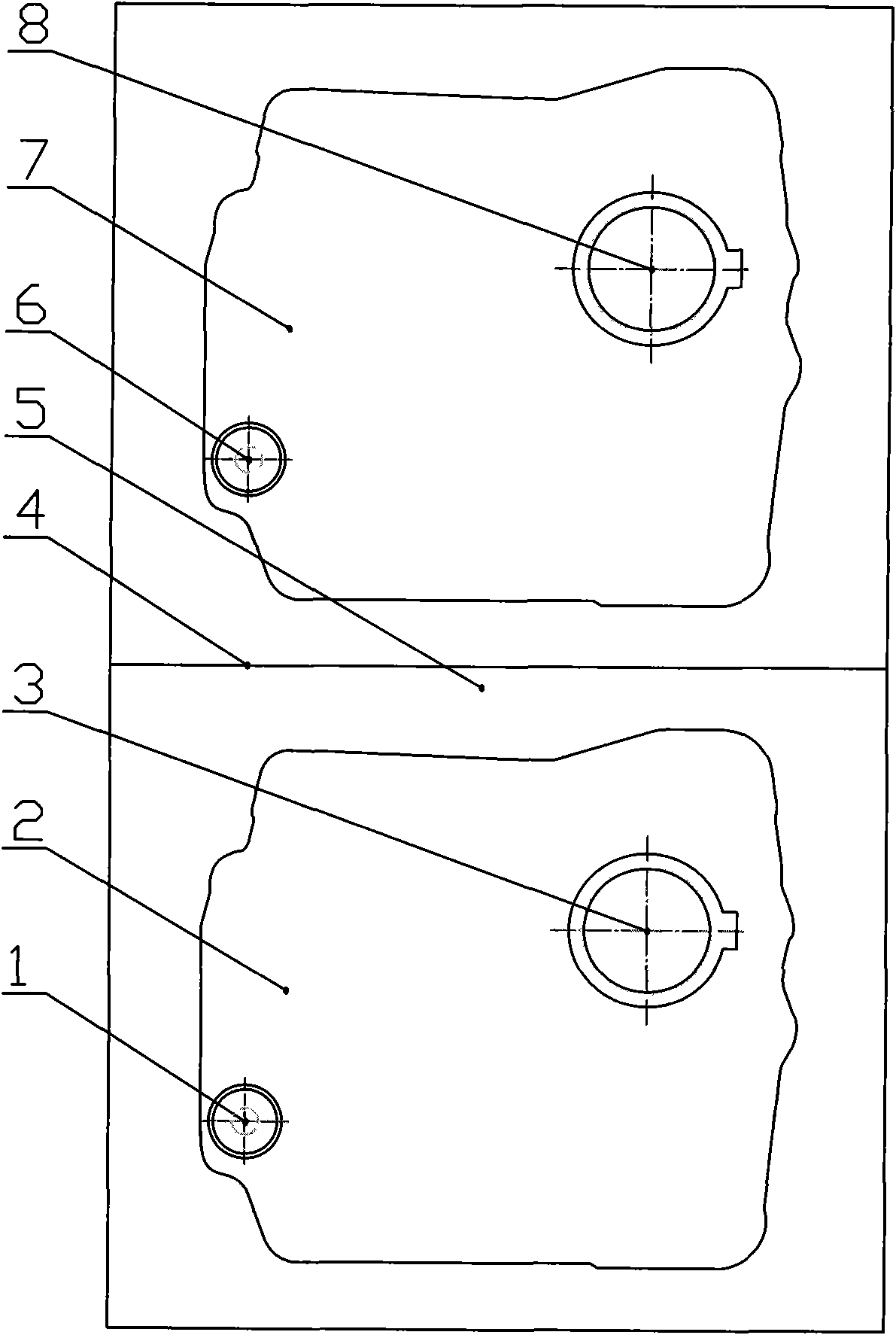

Image

Examples

Embodiment Construction

[0021] The manufacture method of plastic fuel tank of the present invention comprises the following steps:

[0022] (1) Inhale high-density polyethylene, adhesive material, barrier material, and flash material into the storage tanks with sufficient reserves through the vacuum feeding system;

[0023] (2) Dry the barrier material and flash material particles, and control the drying temperature at 90±5°C;

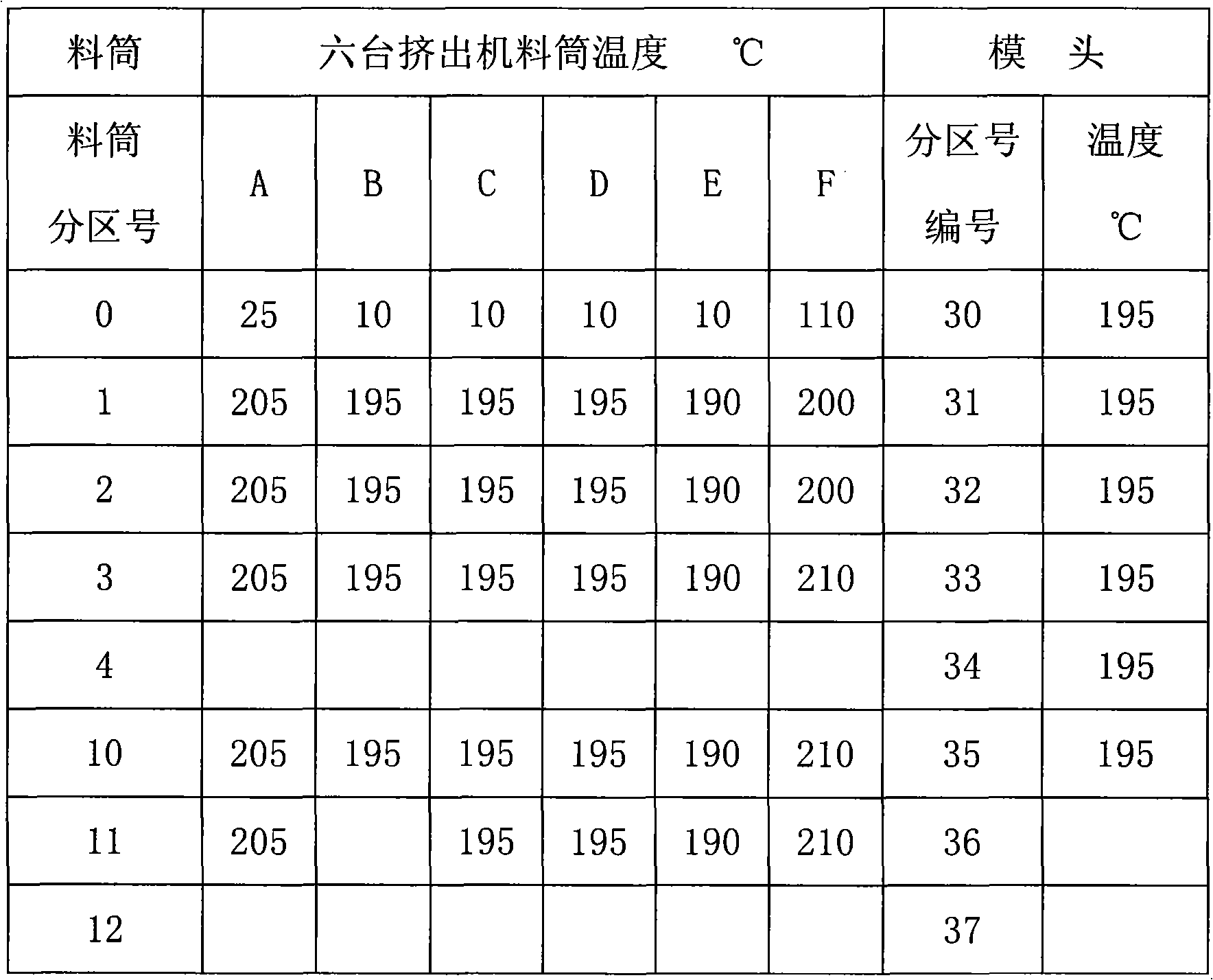

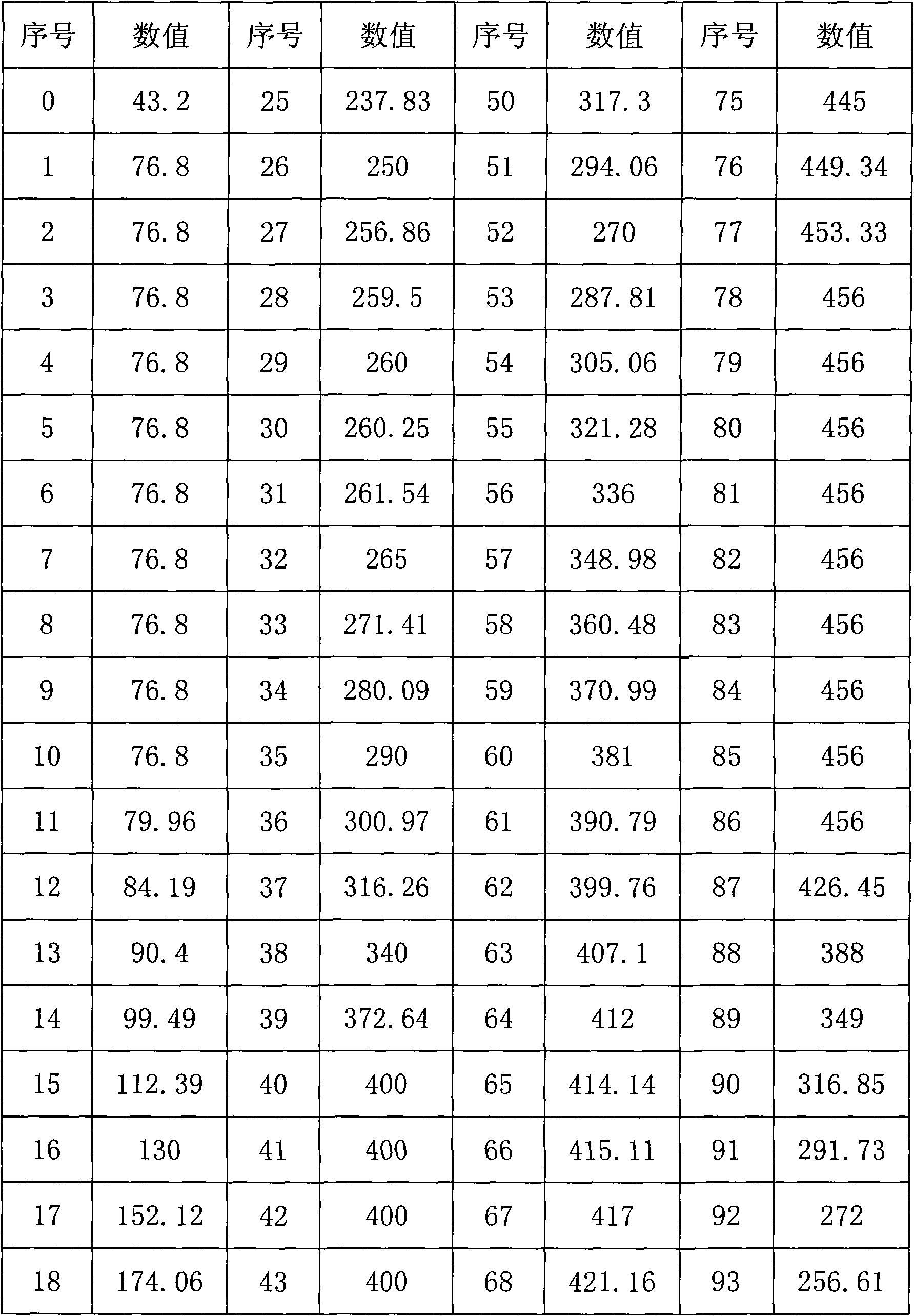

[0024] (3) Use six special extruders with automatic weighing control to pump out qualitative and quantitative melt materials, and continuously extrude a 6-layer parison downward through the co-extrusion die head, and the parison is a cylinder with an open lower end Shaped and vertically hung under the die head, the thickness ratio of each layer from the inside to the outside is: high-density polyethylene: adhesive material: barrier material: adhesive material: recycled material: high-density polyethylene = 37:1.5 : 2: 1.5: 46: 12; Add black color masterbatch to the outer lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com