Process and device for producing horizontally tamped coal cakes

A coal cake, horizontal technology, applied in the petroleum industry, coke oven, etc., can solve the problems of danger, wall damage, etc., and achieve the effect of optimized molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

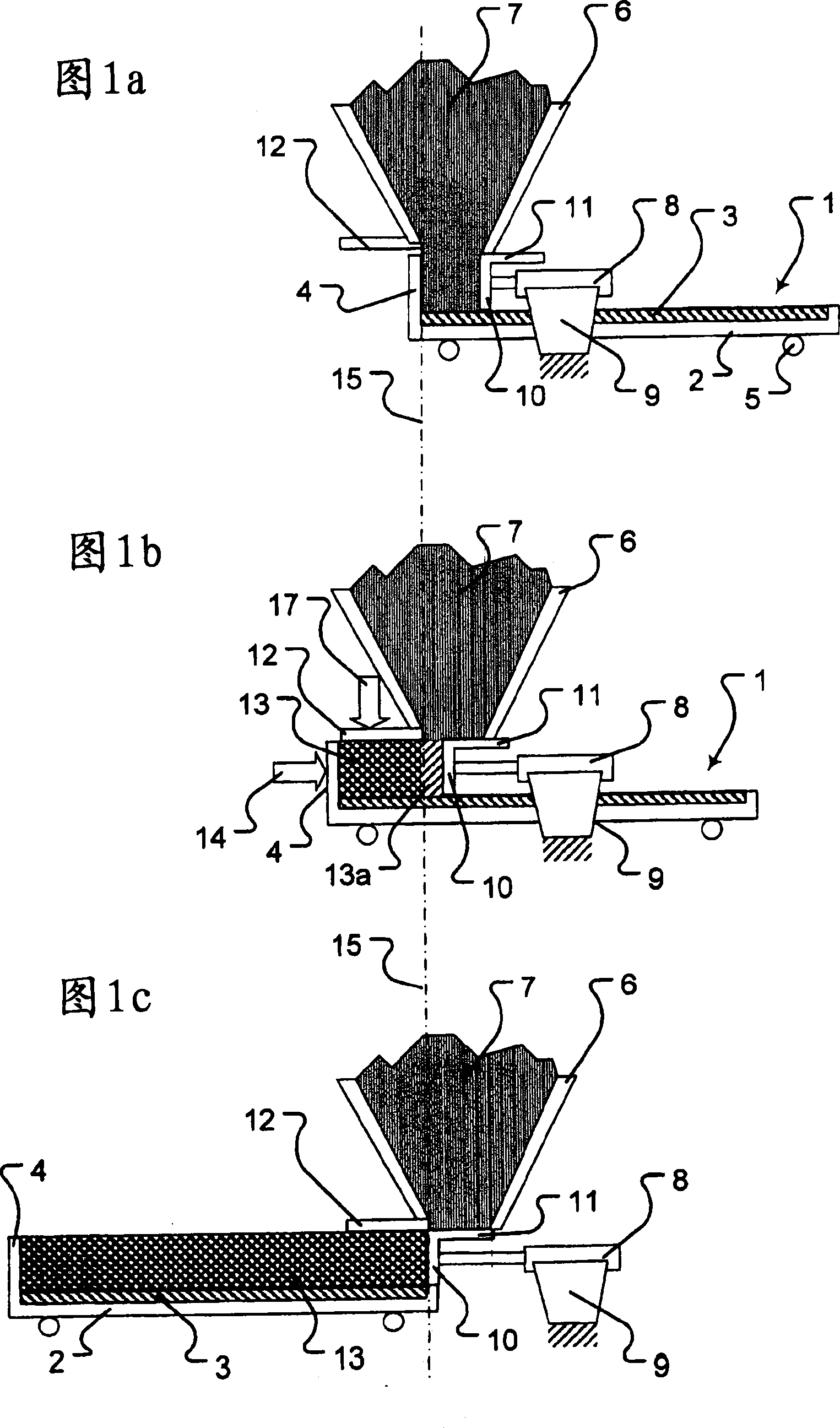

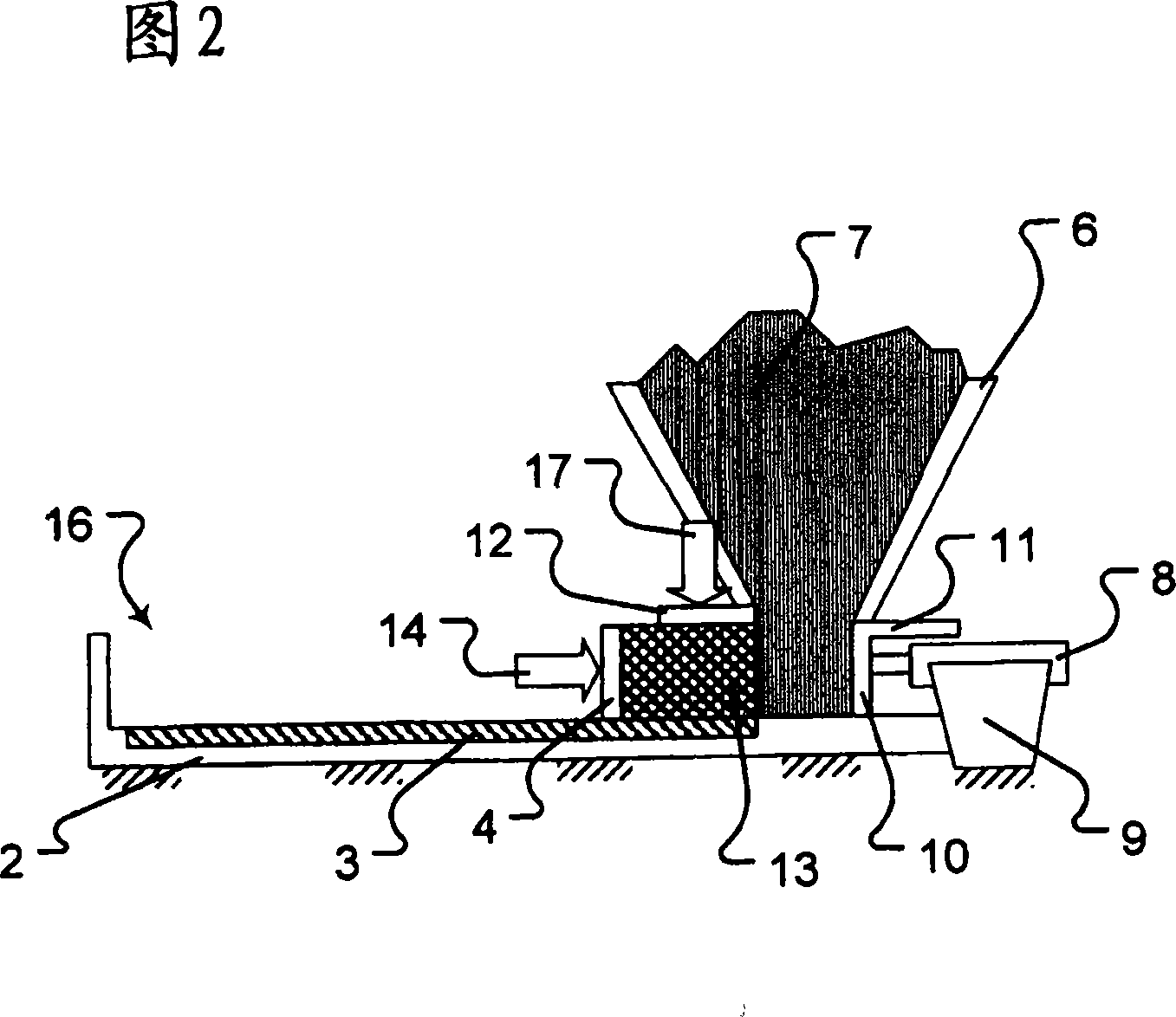

[0036] In FIG. 1 a ), the pressing form in the form of a vehicle 1 can be seen, which essentially consists of a bottom 2 , a tray plate 3 placed on it and which can be removed, and a stop wall 4 arranged in front in the direction of movement. Constitute with the roller 5 that is arranged on the bottom 2 below. A charging chute 6 is arranged above the vehicle 1 , into which loose coal 7 is filled and the loose coal falls all the way onto the vehicle 1 or the cake plate 3 . Also shown in FIG. 1 a) is a hydraulic cylinder 8, which is fastened to a fastening device 9 and which extends parallel to the charging chute 6 and bridges the vehicle 1 below it, so that the vehicle passes under the fixed bridge 9. Move through hydraulic cylinder 8.

[0037]The cylinder head part of the hydraulic cylinder 8 shown in FIG. 1 a) essentially comprises a vertical pressure plate 10 and a horizontally oriented closure plate 11 connected to the pressure plate. In FIG. 1 a ), the pressed cake cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com