Preparation method of laser-induced graphene flexible strain-temperature two-parameter sensor

A laser-induced graphene technology, applied in the field of sensors, can solve the problems of susceptibility to the influence of dopamine, complex sensor structure and preparation process, and complex production process, to achieve excellent electrochemical characteristics, and the production process is green and pollution-free. The effect of high response volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

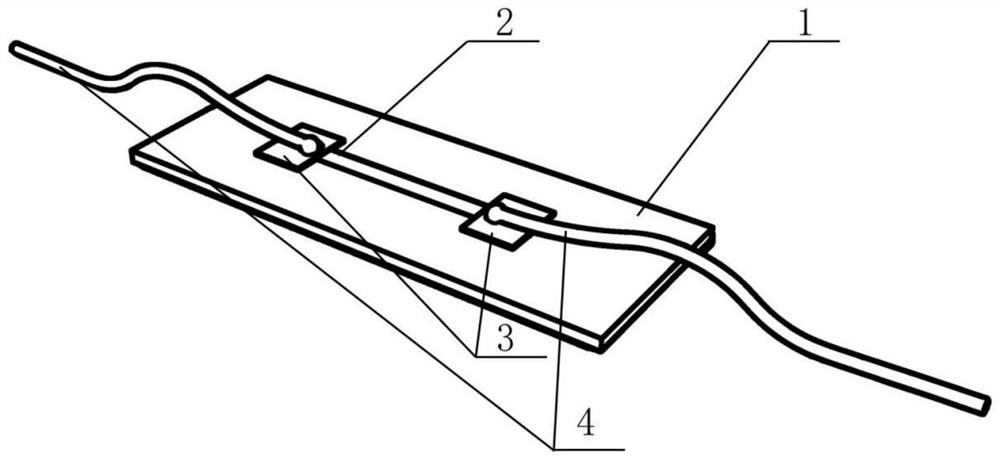

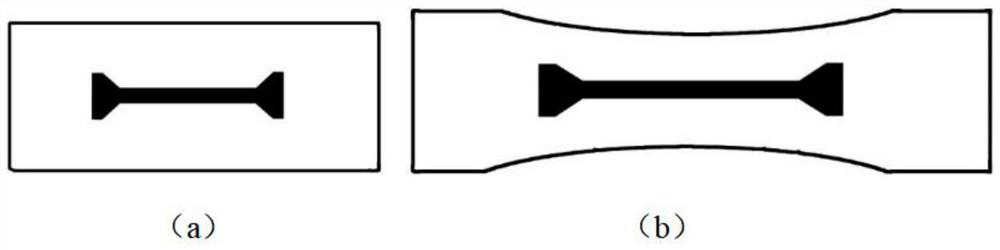

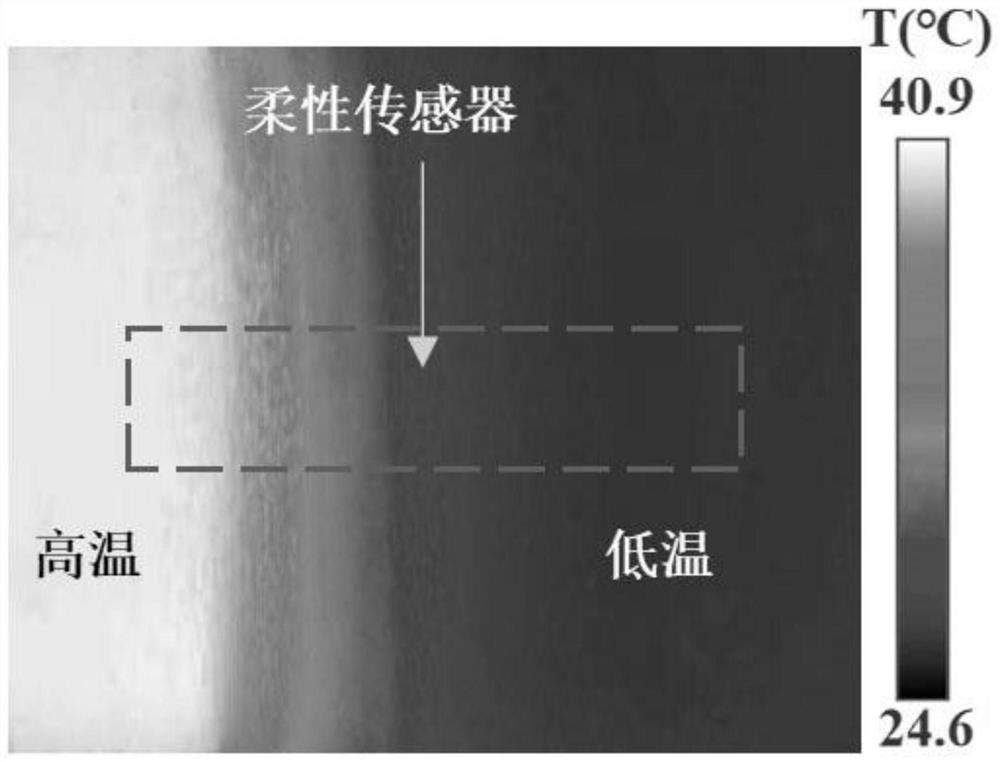

[0044] Schematic diagram of the structure of a laser-induced graphene flexible strain-temperature dual-parameter sensor figure 1 As shown, it includes a flexible and stretchable substrate 1 , a graphene conductive layer 2 , a conductive copper foil 3 , and a wire 4 . The flexible stretchable substrate 1 is placed at the bottom of the sensor and is made of flexible stretchable material PDMS. The upper surface of the flexible stretchable substrate is closely attached to a graphene conductive layer 2, and the graphene conductive layer can be combined with the flexible stretchable substrate. Stretching and bending the base 1 at the same time, the graphene conductive layer has a width of 1.29mm and a length of 17.62mm, and the two ends of the graphene conductive layer are graphene electrodes for connecting external testing equipment; The conductive silver glue is connected to the graphene electrodes at both ends of the graphene conductive layer. The conductive silver glue is evenly...

Embodiment 2

[0061] A laser-induced graphene flexible strain-temperature dual-parameter sensor includes a flexible and stretchable substrate PDMS, a graphene conductive layer, a conductive copper foil, and a wire. The flexible and stretchable substrate is placed at the bottom of the sensor, and the flexible and stretchable graphene conductive layer is placed on the flexible and stretchable substrate for a tight fit.

[0062] The graphene conductive layer and the flexible stretchable substrate are stretched and bent at the same time. The conductive graphene has a width of 1.29mm and a length of 17.62mm. Both ends of the graphene electrodes are used to connect external testing equipment.

[0063] The copper foil is connected to the electrodes at both ends of the graphene through conductive silver glue. The conductive silver glue is evenly applied, and then the conductive copper foil is pasted on it, and placed on a heating table at 80°C for 40 minutes. After it is completely cured, solder is ...

Embodiment 3

[0068] A laser-induced graphene flexible strain-temperature dual-parameter sensor has different resistance change rates under different stretching rates, such as Figure 6As shown, the sensor responds to the resistance change rate at 5%, 10%, 15%, and 20% stretching rates respectively. Repeat stretching and releasing 7 times at each stretching rate, the stretching resistivity increases, and the release can basically be achieved. It has fully recovered, and the performance of many experiments is still good. At a stretch rate of 5%, the sensor has a 180% strain resistance change rate response; at a stretch rate of 10%, the sensor has a 750% strain resistance change rate response; at a stretch rate of 15% , the sensor has a 1200% strain resistance change rate response (the ordinate is the resistance change rate=(stretched resistance-initial resistance) / initial resistance*100%); at a stretch rate of 20%, the sensor has 1600 % of the strain resistance change rate response.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com