Drum-type tractor band-type brake monitoring device

A monitoring device and traction machine technology, applied in elevators, mechanical equipment, transportation and packaging, etc., can solve the problem of not being able to directly or indirectly monitor whether the braking torque of the traction machine meets the requirements for use, and reduce the safety performance of the traction machine. , easy to produce errors and other problems, to achieve the effect of improved safety performance, reliable use and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

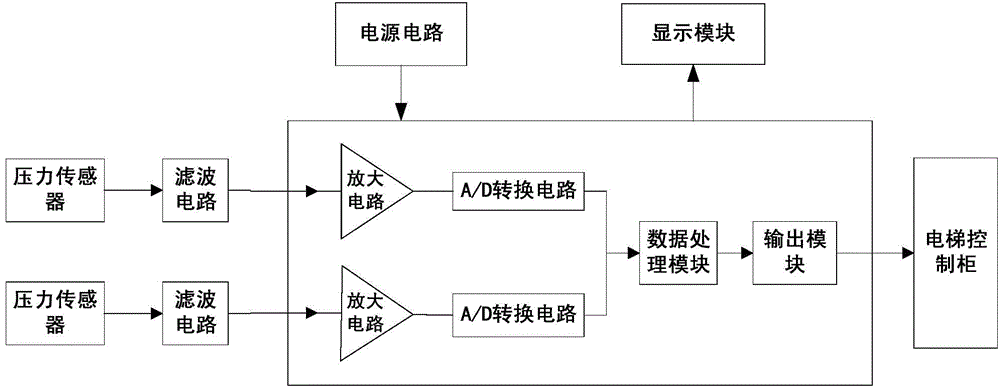

[0018] As shown in the figure, a brake monitoring device for a drum tractor provided by the present invention includes a power circuit, a pressure sensor, a signal processor and a display module; arm stress change signal; the pressure sensor inputs the stress change signal adopted into the signal processor for data processing to obtain the traction machine torque monitoring signal; the monitoring signal element is input to the display module for display; the power circuit and Signal processor connection.

[0019] The pressure sensor is a strain gauge; the strain gauge is arranged on a strain gauge carrier installed on the brake arm.

[0020] A filtering circuit is also included, and the filtering circuit is arranged between the pressure sensor and the signal processor.

[0021] The power supply circuit, signal processor and display module are arranged on the circuit board; the circuit board is arranged in the elevator control cabinet.

[0022] The strain gauge carrier is mad...

Embodiment 2

[0025] The difference between this embodiment and embodiment 1 is only:

[0026] This embodiment provides a drum type traction machine brake monitoring device, the principle of which is to pass the strain gauge through a special adhesive; the adhesive provided in this embodiment uses a polymeric adhesive as the connection between the strain gauge and the carrier (matrix) substance. Mainly divided into two categories: 1: Epoxy resin binder. 2:502 Glue. The main components and proportions of the former are: epoxy resin 100: ethylenediamine 7: dibutyl ester 5. The main components of the latter are: ethyl cyanoacrylate plus a small amount of plasticizer. In addition, the composition and ratio of the glue used as the insulation cover of the strain gauge is: epoxy resin 100: low molecular weight polyamide 100. Tightly adhere to the carrier and fix the carrier on the substrate (brake arm) that generates mechanical strain. When the substrate is stressed and the stress changes, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com