Q345 Z-direction extra-thick low-alloy high-strength structure steel plate and production method thereof

A low-alloy high-strength, structural steel plate technology, applied in the field of steel plate and its processing technology in the metallurgical industry, can solve the problems of less than 90% qualified rate of initial test performance, increased difficulty of controlled rolling of extra-thick steel plate, unstable product performance and quality, etc. Achieve the effect of good comprehensive product performance, reasonable rolling process and reasonable cooling scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific examples.

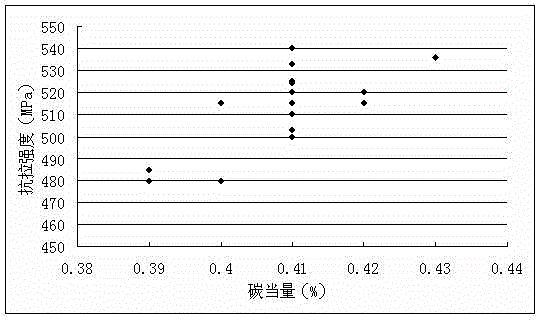

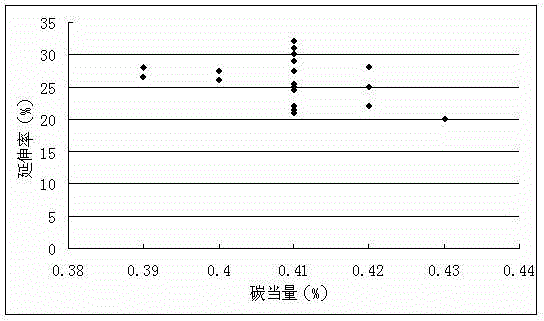

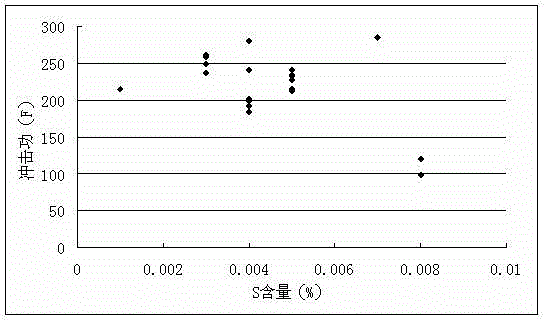

[0020] The thickness of the Z-direction extra-thick low-alloy high-strength structural steel plate of Q345 is 50-70mm, and the steel plate contains the following chemical composition in mass percentage: C: 0.15-0.16; Si: 0.27-0.32; Mn: 1.39-1.45; P: 0.010 ~0.013; S: 0.001~0.007; Al: 0.029~0.049; V: 0.056~0.064; Ti: 0.013~0.016; Nb: 0.012~0.014; the rest is Fe; The calculation complies with the provisions of GB / T 1591.

[0021] A production method for producing the above-mentioned Z-direction extra-thick low-alloy high-strength structural steel plate of Q345, the method includes billet heating, high-pressure water descaling, rough rolling of billet, finish rolling of billet, post-rolling cooling and heat treatment processes.

[0022] In the steel billet heating process of the above-mentioned production method, the equipment and technical advantages of the regenerativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com