Method for fill feeding in papermaking

A calcium carbonate filler, high-efficiency technology, applied in the field of papermaking industry, can solve the problems of reduced strength and sizing degree, difficult to achieve paper ash content, increased chemical consumption, etc., to improve ash content, surface strength and wire filler retention rate Improvement and reduction of drying steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

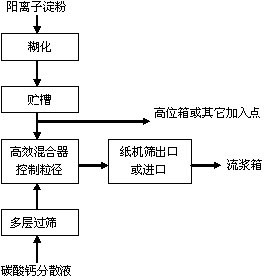

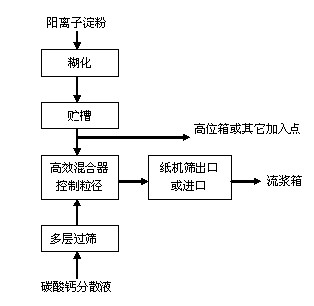

Method used

Image

Examples

Embodiment 1

[0017] Light offset paper (quantitative 75g / m 2 ) according to the ratio of 4% bleached kraft softwood pulp, 86% chemical mechanical pulp (APMP), and 10% CTMP pulp; the beating concentration of bleached kraft softwood pulp is 3.0±0.5%, and the beating degree is 45±2 0 SR; chemical mechanical pulp (APMP) beating concentration 2.5-4.0%, beating degree ≥ 42 0 Sr. The filler is light calcium carbonate, quaternary ammonium cationic starch: the concentration is 1%, the ratio of starch to filler is 1:100, the light calcium carbonate is filtered through a 80-120 mesh multi-layer sieve, and mixed with cationic starch through a high-efficiency mixer to sieve , and then join the paper machine sieve together. Addition of retention aid PAM: 0.52kg / T paper, cationic starch addition: 9.5 kg / T paper, AKD addition: 11 kg / T paper, of which 5.5 kg / T paper in pulp, 5.5 kg surface sizing / T paper. From the test results of the wet end, after using filler + starch pre-flocculation, the retention...

Embodiment 2

[0020] Lightweight offset paper (quantitative 65g / m 2 ) according to the ratio of 4% bleached kraft softwood pulp, 80% chemical mechanical pulp (APMP), and 16% CTMP pulp; the beating concentration of bleached kraft softwood pulp is 3.0±0.5%, and the beating degree is 45±2 0 SR; chemical mechanical pulp (APMP) beating concentration 2.5-4.0%, beating degree ≥ 42 0 Sr. The filler is heavy calcium carbonate, quaternary ammonium cationic starch: the concentration is 1%, the ratio of starch to filler is 0.5:100, the heavy calcium carbonate is filtered through a 80-120 mesh multi-layer sieve, and then mixed with cationic starch and sieved through a high-efficiency mixer , and then join the paper machine sieve together. Addition of retention aid PAM: 0.50kg / T paper, cationic starch addition: 9.6 kg / T paper, AKD addition: 10 kg / T paper, of which 5.0 kg / T paper for pulp, 5.0 kg for surface sizing / T paper. From the test results of the wet end, after using filler + starch pre-floccul...

Embodiment 3

[0022] Light offset paper (quantitative 75g / m 2 ) according to the ratio of 4% bleached kraft softwood pulp, 86% chemical mechanical pulp (APMP), and 10% CTMP pulp; the beating concentration of bleached kraft softwood pulp is 3.0±0.5%, and the beating degree is 45±2 0 SR; chemical mechanical pulp (APMP) beating concentration 2.5-4.0%, beating degree ≥ 42 0 Sr. The filler is light calcium carbonate and heavy calcium carbonate (filler ratio: light calcium: heavy calcium = 50:50), quaternary ammonium cationic starch: concentration 1%, starch to filler ratio 0.5:100, calcium carbonate through 80-120 After being filtered through a multi-mesh sieve, it is mixed with cationic starch and sieved through a high-efficiency mixer, and then added to the paper machine sieve together. Addition of retention aid PAM: 0.52kg / T paper, cationic starch addition: 9.6 kg / T paper, AKD addition: 11 kg / T paper, of which 5.5 kg / T paper in the pulp, 5.5kg surface sizing / T paper. From the test result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com