High-strength anti-deformation corrugated paper box and production technology

A technology of corrugated box and production process, which is applied in the field of corrugated box, can solve the problem of low strength of corrugated box, and achieve the effect of simple structure, increased service life and increased structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

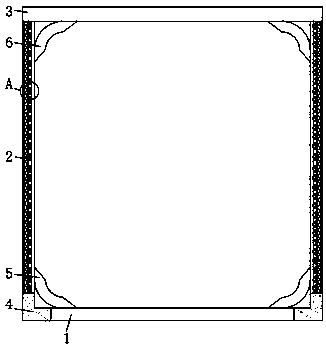

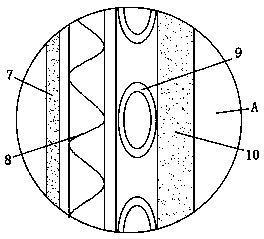

Image

Examples

Embodiment 1

[0056] A production process of a high-strength anti-deformation corrugated box, comprising the following steps:

[0057] A: Raw material pretreatment: Put waste paper, bamboo stalks and wheat straws into a pulverizer to process into scraps, then dissociate the scraps into fibers, and then filter and screen to remove impurities in the fibers;

[0058] B: Beating: Pour the crushed fiber into the refiner, add silica, vinyl acetate, polyethylene fiber and water, the ratio of silica, vinyl acetate, polyethylene fiber is 1:1: 5. Then beat the pulp to obtain a uniformly mixed pulp, and then place the pulp for 0.5 hours, and the concentration of the pulp is 5-10%;

[0059] C: Enzymolysis: Cool the fiber slurry to 20°C, add amylase and acid-base regulator, the enzyme activity of amylase is 1.8 million U / g, the enzymolysis treatment time is 1h, and the pH of the slurry is controlled at 4 ;

[0060] D: Preparation of paper: use a paper machine to dehydrate the fiber slurry and press it...

Embodiment 2

[0068] A production process of a high-strength anti-deformation corrugated box, comprising the following steps:

[0069] A: Raw material pretreatment: Put waste paper, bamboo stalks and wheat straws into a pulverizer to process into scraps, then dissociate the scraps into fibers, and then filter and screen to remove impurities in the fibers;

[0070] B: Beating: Pour the crushed fiber into the refiner, add silica, vinyl acetate, polyethylene fiber and water, the ratio of silica, vinyl acetate, polyethylene fiber is 1:1: 5. Then beat the pulp to obtain a uniformly mixed pulp, then place the pulp for 1 hour, and the concentration of the pulp is 8%;

[0071] C: Enzymolysis: Cool the fiber slurry to 30°C, add amylase and acid-base regulator, the enzyme activity of amylase is 1.8 million U / g, the enzymolysis treatment time is 1.5h, and the pH of the slurry is controlled at 5;

[0072] D: Preparation of paper: use a paper machine to dehydrate the fiber slurry and press it into sha...

Embodiment 3

[0080] A production process of a high-strength anti-deformation corrugated box, comprising the following steps:

[0081] A: Raw material pretreatment: Put waste paper, bamboo stalks and wheat straws into a pulverizer to process into scraps, then dissociate the scraps into fibers, and then filter and screen to remove impurities in the fibers;

[0082] B: Beating: Pour the crushed fiber into the refiner, add silica, vinyl acetate, polyethylene fiber and water, the ratio of silica, vinyl acetate, polyethylene fiber is 1:1: 5. Then beat the pulp to obtain a uniformly mixed pulp, then place the pulp for 2 hours, and the concentration of the pulp is 10%;

[0083] C: Enzymolysis: Cool the fiber slurry to 40°C, add amylase and acid-base regulator, the enzyme activity of amylase is 1.8 million U / g, the enzymolysis treatment time is 2 hours, and the pH of the slurry is controlled at 6 ;

[0084] D: Preparation of paper: use a paper machine to dehydrate the fiber slurry and press it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com