Low-temperature pipeline steel used for LNG transmission trunk line and preparation method thereof

A pipeline steel, low temperature technology, applied in the field of pipeline steel, to achieve the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0024] One, the chemical composition of the steel plate in the embodiment is as shown in Table 1 below:

[0025] Table 1 steel plate chemical composition (wt%)

[0026]

[0027] The above examples are all chemical composition weight percentages, and the balance is Fe and unavoidable impurity elements.

[0028] Two, embodiment technological system is as shown in table 2 below:

[0029] Table 2 embodiment technological system

[0030]

[0031] Among them, the welding process adopts automatic submerged arc welding with inner four wires and outer four wires, with a voltage of 36-42V and a current of 550-1050A.

[0032] Three, embodiment mechanical properties are as shown in table 3 below:

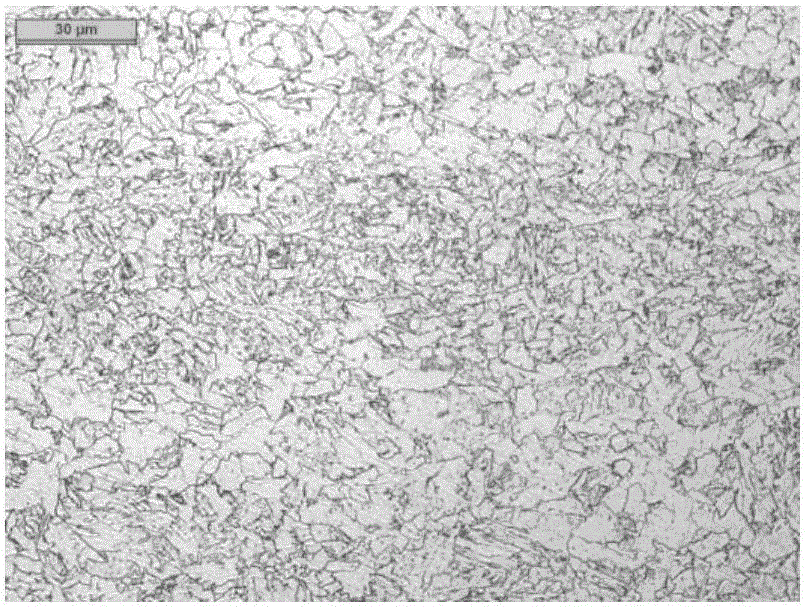

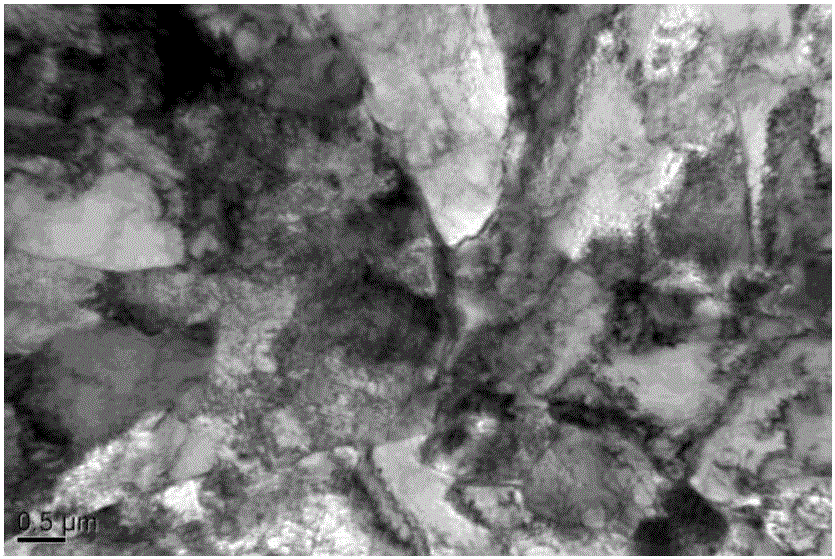

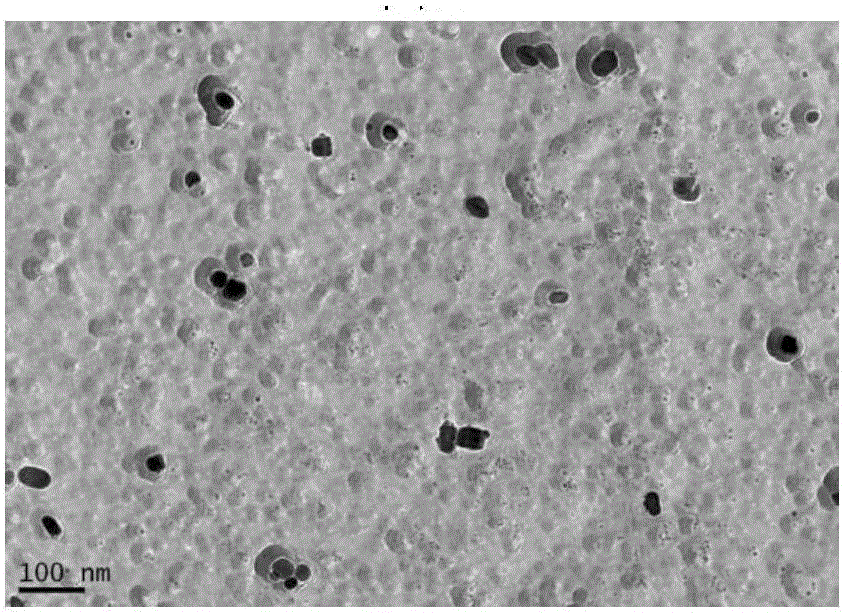

[0033] The metallographic structure of the low-temperature pipeline steel for LNG gas transmission main line produced in Examples 1-5 is mainly fine quasi-polygonal ferrite, and there is a small amount of granular bainite structure; 1-5% of niobium-titanium composite is distributed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com