Broadband wave-transparent double-layer composite ceramic radome cover body and preparation method thereof

A double-layer composite, ceramic antenna technology, applied in the directions of the antenna, antenna parts, radiation unit cover, etc., can solve the problems of low connection strength of the cover body, limited application range, low assembly accuracy, etc. The effect of ensuring strength and electrical properties, and improving the speed of ceramic densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

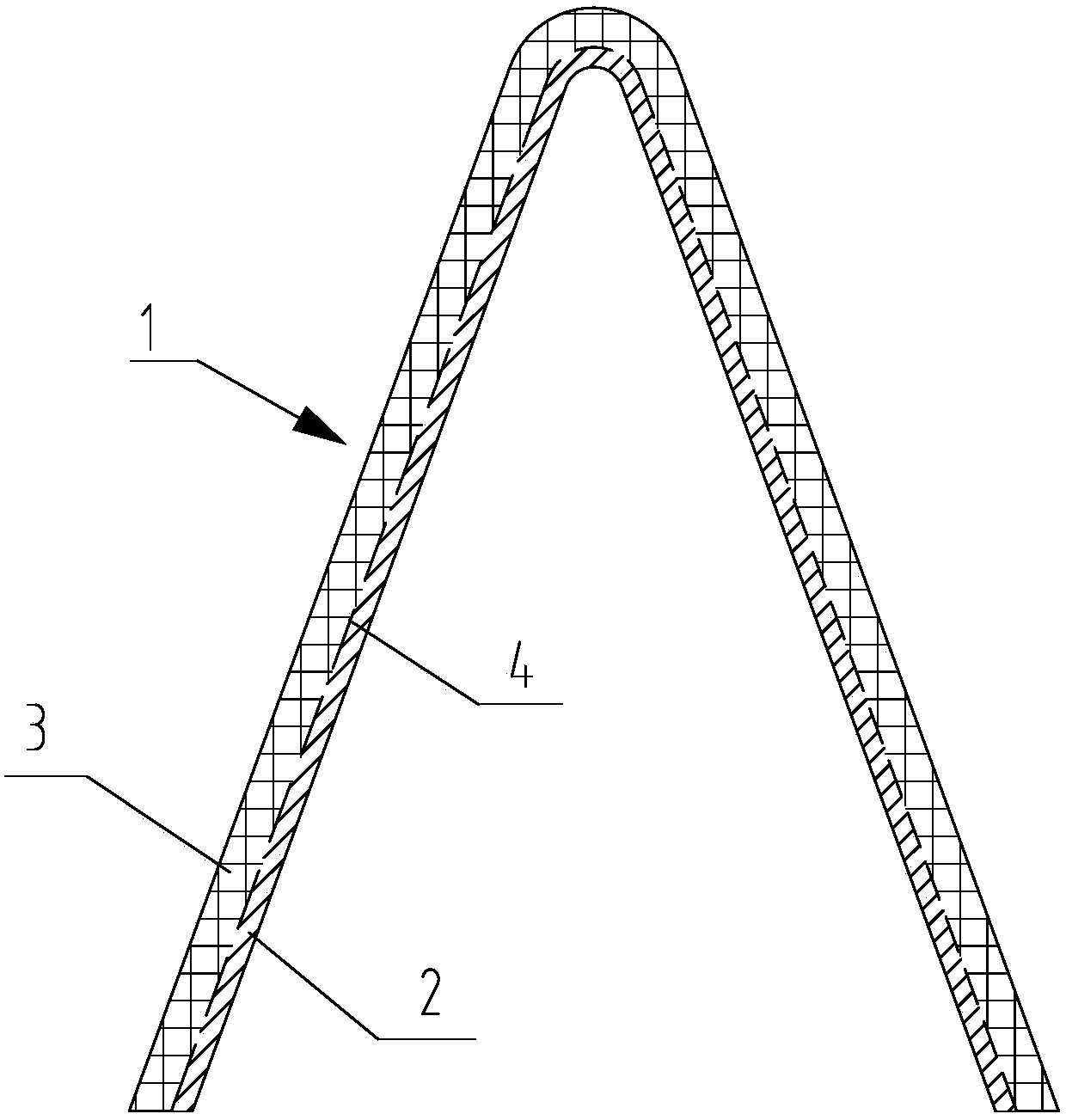

[0031] A method for preparing a broadband wave-transparent double-layer composite ceramic radome cover body, comprising the following steps:

[0032] 1) Weaving of profiling fabric: According to the structural size of the double-layer cover body of the radome, determine the inner and outer structural dimensions of the profiling fabric (the thickness of the profiling fabric is 24mm); first use hollow quartz fiber cloth (thickness is 0.5mm) and hollow quartz fiber mesh tire (area density 50g / cm 2 ) to form an inner layer by profiling and alternate laying layers, and then lay a diaphragm layer (thickness 0.05mm) formed by a polytetrafluoroethylene film on the outer surface of the inner layer, and then use a solid quartz fiber cloth ( The thickness is 0.5mm) and the layer is stitched into the outer layer, and finally the overall stitching forms an integrated profiling fabric;

[0033] 2) Pretreatment of the profiling fabric: soak the profiling fabric in analytical pure acetone fo...

Embodiment 2

[0042] A method for preparing a broadband wave-transparent double-layer composite ceramic radome cover body, comprising the following steps:

[0043] 1) Weaving of profiling fabric: According to the structural size of the double-layer cover body of the radome, determine the inner and outer structural dimensions of the profiling fabric (thickness of the profiling fabric is 40mm); first use hollow quartz fiber cloth (thickness of 0.5mm) and hollow quartz fiber mesh tire (area density 50g / cm 2 ) to form an inner layer by profiling and alternate laying layers, and then lay a diaphragm layer (thickness 0.05mm) formed by a polytetrafluoroethylene film on the outer surface of the inner layer, and then use a solid quartz fiber cloth ( The thickness is 0.5mm) and the layer is stitched into the outer layer, and finally the overall stitching forms an integrated profiling fabric;

[0044] 2) Pretreatment of the profiling fabric: soak the profiling fabric in analytically pure acetone for ...

Embodiment 3

[0053] A method for preparing a broadband wave-transparent double-layer composite ceramic radome cover body, comprising the following steps:

[0054] 1) Weaving of profiling fabric: According to the structural size of the double-layer cover body of the radome, determine the inner and outer structural dimensions of the profiling fabric (thickness of the profiling fabric is 20mm); first use hollow quartz fiber cloth (thickness of 0.1mm) and hollow quartz fiber mesh tire (area density 30g / cm 2 ) to form an inner layer by profiling and alternately laying layers, and then lay a diaphragm layer (0.03mm in thickness) formed by a polytetrafluoroethylene film on the outer surface of the inner layer, and then use a solid quartz fiber cloth ( The thickness is 0.1mm) and the layer is stitched into the outer layer, and finally the overall stitching is formed to form an integrated profiling fabric;

[0055] 2) Pretreatment of the profiling fabric: soak the profiling fabric in analytical pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com