Manufacturing process of mold for manufacturing carbon fiber box

A manufacturing process, carbon fiber technology, applied in the field of mechanical manufacturing process, can solve the problems of heavy product quality, inability to guarantee the strength of manufactured products, and high manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

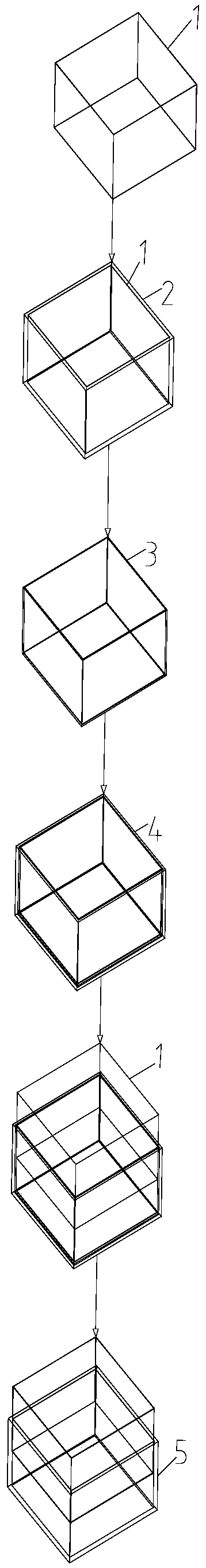

[0025] Such as figure 1 , a manufacturing process of a mold for manufacturing a carbon fiber box, comprising a male mold 1, comprising the following steps;

[0026] Step 1: Spray red CCP gel coat on the outer surface of male mold 1 and wait for curing to form gel coat layer 2; the gel coat is sprayed at one time, and the spraying amount of gel coat is 800g / ㎡, 850g / ㎡, 900g / ㎡, and the thickness is in Between 0.75mm, 0.8mm, and 0.85mm, the thickness of the gel coat layer is measured by a thickness gauge;

[0027] The second step: paste non-woven fabric on the gel coat layer to form a surface felt layer; spread a layer of non-woven fabric on the surface of the cured gel coat layer, and connect the non-woven fabric and the gel coat layer through resin, and the amount of resin is 500g / ㎡, and spread evenly, after the surface felt layer is cured, pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com