High-performance synthetic rubber asphalt waterproof coiled material

A technology of bitumen waterproofing membrane and synthetic rubber, which is applied in the direction of roofing, building insulation material, roofing and other directions using flexible materials, which can solve the problems of poor reliability and water leakage at joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and typical embodiment:

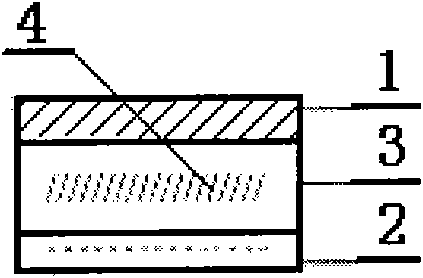

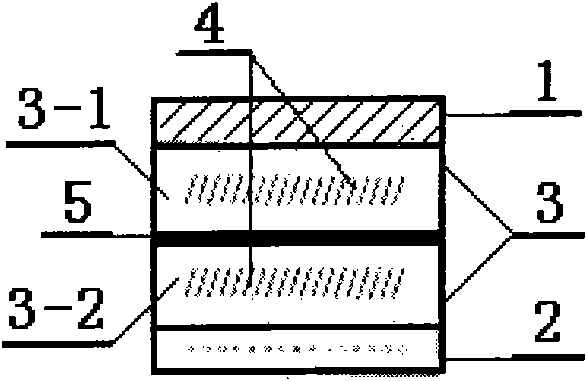

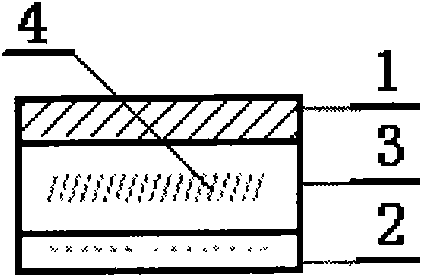

[0021] exist figure 1 Among them, the main body of the high-performance synthetic rubber bitumen waterproof coiled material of the present invention is composed of an upper covering layer 1, a lower covering layer 2 and an intermediate waterproof layer, and is characterized in that the upper covering layer 1 is made of polyethylene polypropylene fiber, polyethylene film or metal aluminum foil As a role, the lower cover layer 2 is made of needle-punched polyester non-woven fabric, and the intermediate waterproof layer is made of a modified asphalt compound layer 3 composed of a modified asphalt compound 4, wherein: the modified Asphalt compound 4 is made by comprehensively modifying the asphalt by adding a modifier to the main asphalt, and the components include the main asphalt, modifier and engine oil. The modifier is composed of a high molecular po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com