Asphalt smoke comprehensive environmental protection treatment system and applications thereof

A technology for environmental protection treatment and asphalt fume, which is applied in the direction of combined devices, combustion methods, lighting and heating equipment, etc., can solve the problems that the plasma unit is easy to be corroded, affects the surrounding environment, frequent cleaning, etc., and achieves broad market application prospects and saves energy. Energy, full use of resources and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

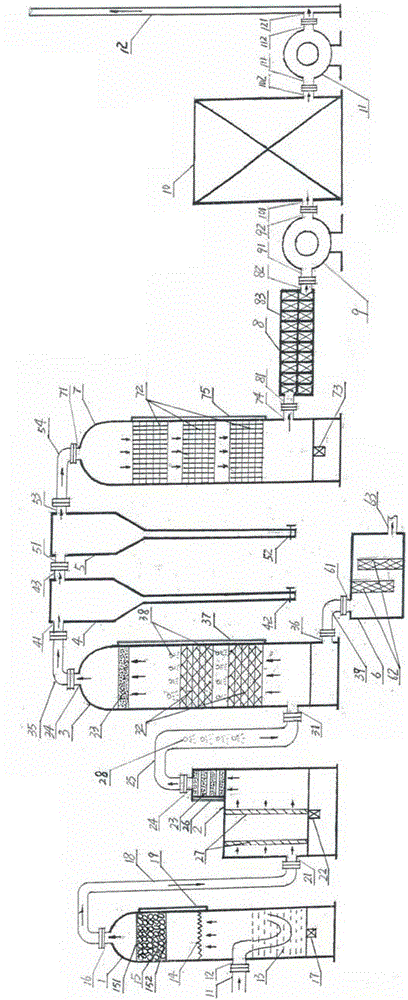

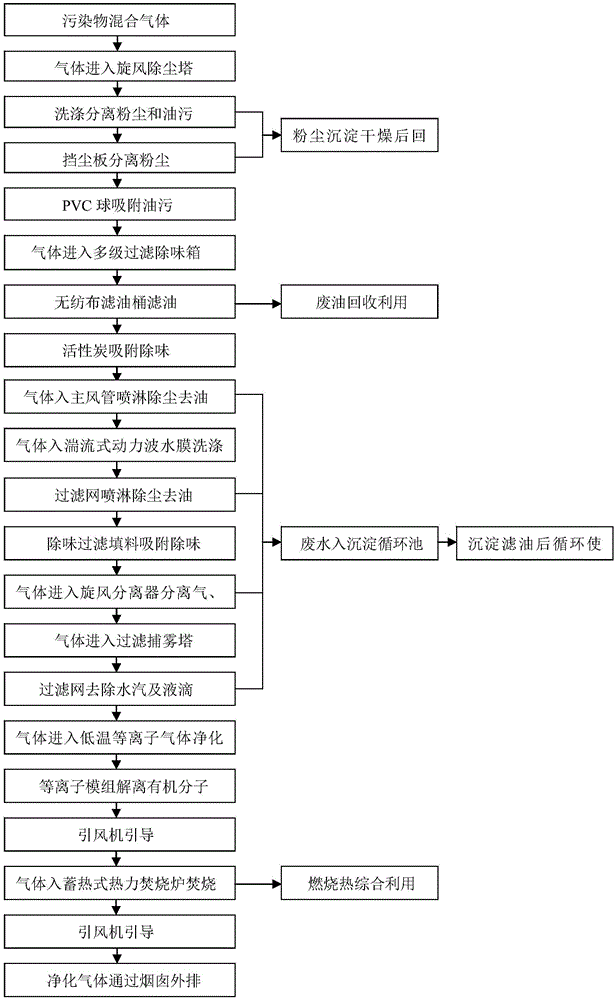

[0048] A comprehensive environmental protection treatment system for asphalt flue gas, its structure is as follows figure 1 As shown, it includes environmental protection treatment equipment, gas transmission pipeline, induced draft fan and chimney 12. The environmental protection treatment equipment includes cyclone dust removal tower 1, multi-stage filter deodorization box 2, turbulent flow power wave water film washing tower 3, cyclone separator 4. Cyclone separator 5, sedimentation circulation pool 6, filter mist trapping tower 7, low-temperature plasma waste gas purifier 8 and regenerative thermal incinerator 10, induced draft fan 9 is set on low-temperature plasma waste gas purifier 8 and regenerative thermal incinerator Between the furnaces 10, the induced draft fan 11 is arranged between the regenerative thermal incinerator 10 and the chimney 12; Between the output pipe interface 16 of the dedusting tower 1 and the input pipe interface 21 of the multi-stage filter deod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com