Broad passage plate heat exchanger heat radiation board and its surface intensifying process

A plate heat exchanger and radiating plate technology, applied in indirect heat exchangers, heat exchanger types, metal material coating processes, etc., can solve the problem of short effective life, large maintenance workload, work reliability, Poor stability and other problems, to achieve obvious technological advancement, improve wear resistance, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

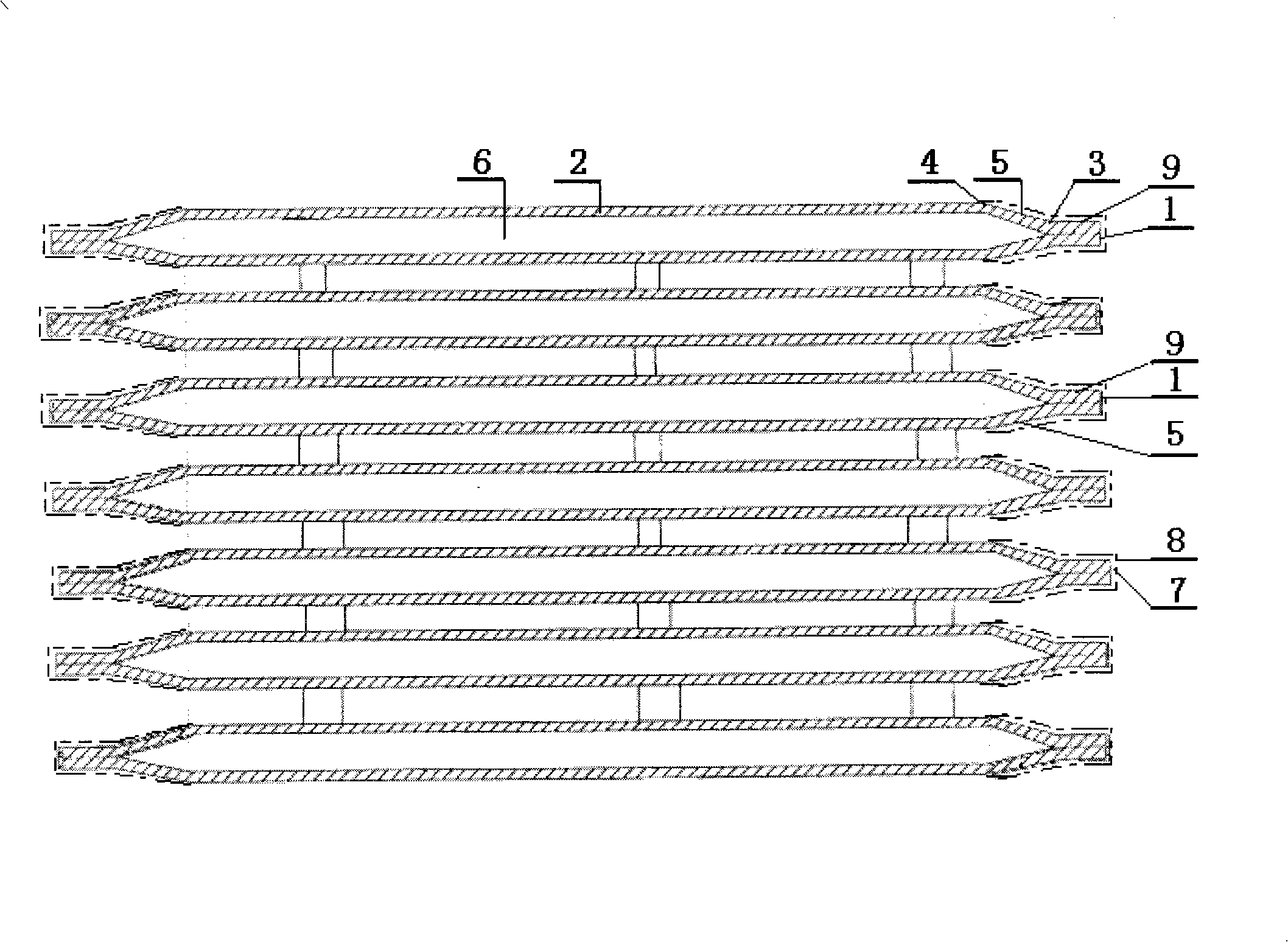

[0017] In the accompanying drawings, the main body of the radiator plate of the wide channel plate heat exchanger of the present invention is a double-plate composite structure, consisting of flat sections 1 at both ends, extended sections 2 in the middle, and end parts 3 located at the flat sections 1 at both ends and extended sections in the middle. 2 is composed of an inclined diverging section 5 between the initial parts 4, and a hollow water flow channel 6 is arranged in the middle expansion section 2, and the feature is that on the outer surfaces of the flat sections 1 at both ends and the inclined diverging section 5, there are additionally provided with The erosion-resistant strengthening layer 9 is composed of a layered high-hardness alloy powder unsprayed layer 7 and a high-strength resin sealing layer 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com