Injection mould servo synchronous automatic thread demoulding mechanism and control method thereof

A synchronous automatic thread removal technology, which is applied to threaded products, other household appliances, household appliances, etc., can solve the problems of small application range and low precision, and achieve the effect of wide application range, convenient operation and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

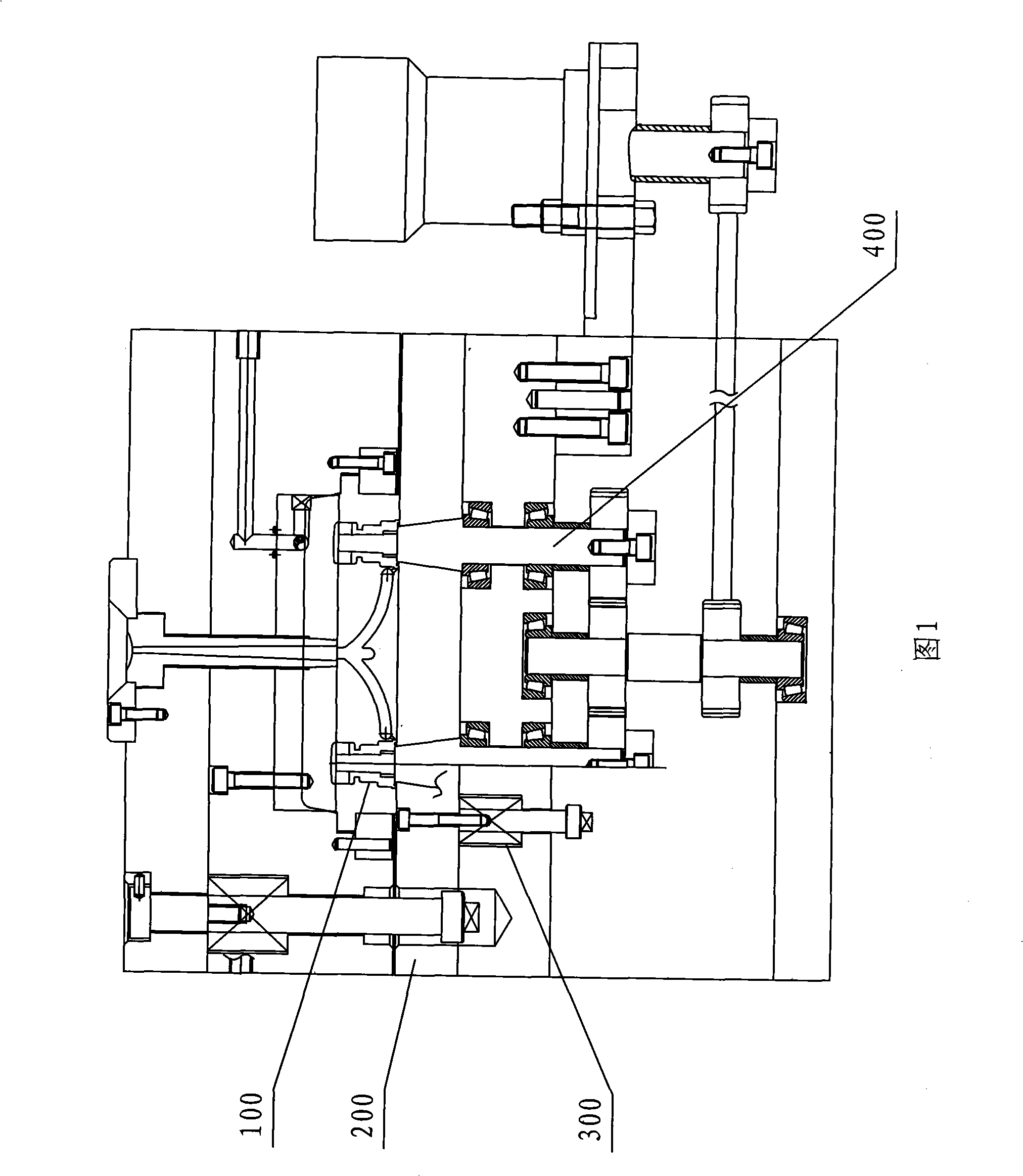

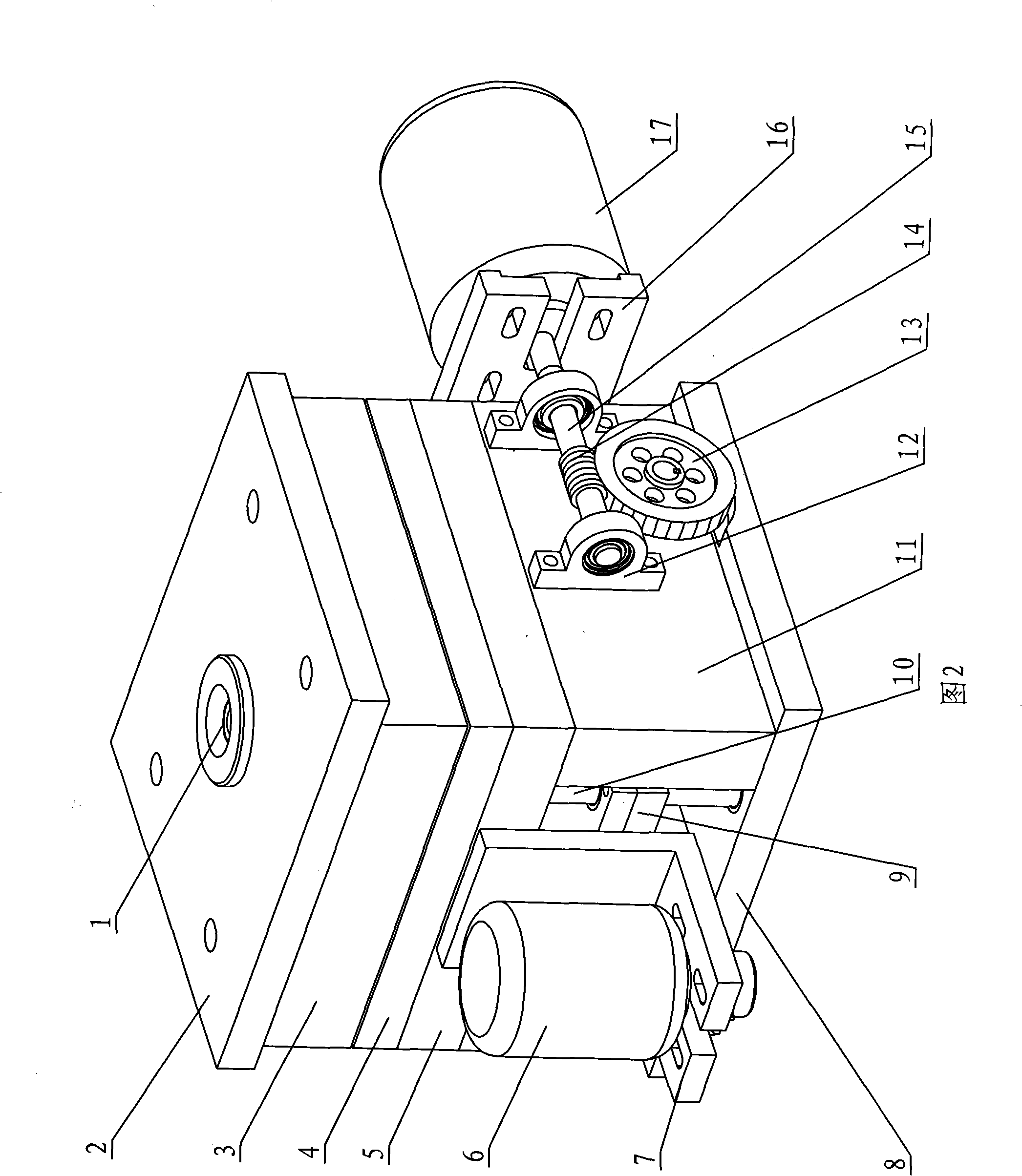

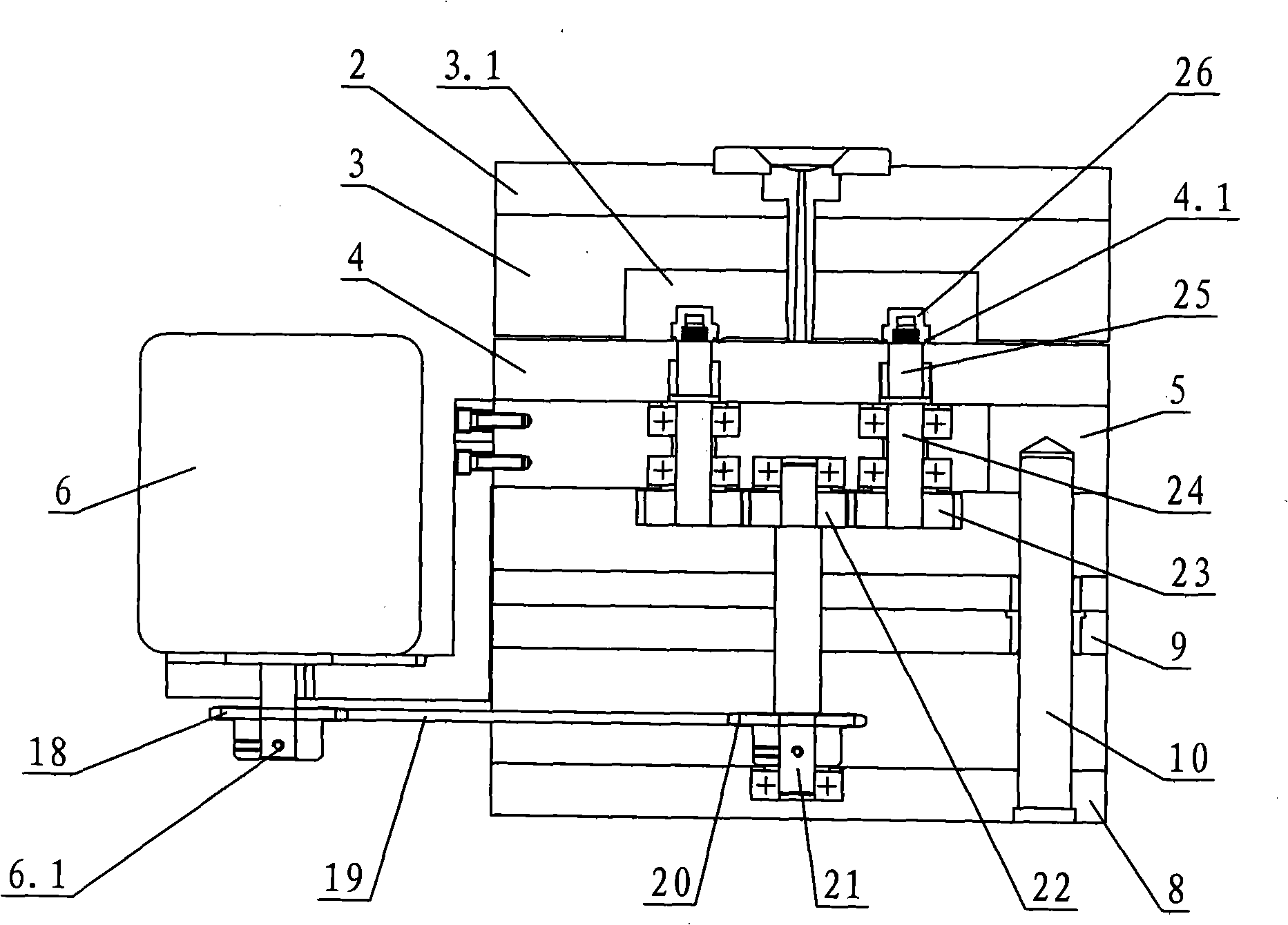

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] See Figure 2- Figure 6 , the servo synchronous automatic thread removal mechanism of this injection mold includes a mold base, a fixed template 3, a push plate 4, a movable template 5, a threaded core 25 and an injection molded part 26 with threads, and the threaded core 25 and the push plate 4 are respectively connected with The rotating mechanism and the lifting mechanism are connected by transmission, and the two mechanisms are controlled by the control system so that the axial speed at which the rotating mechanism unscrews the thread is consistent with the speed at which the lifting mechanism pushes out the push plate. The formwork includes a top plate 2, a side plate 11 and a bottom plate 8. The top plate, the fixed formwork 3, the push plate 4, the movable formwork 5, the side plates and the bottom plate are connected sequentially from top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com