Crystalline silicon ingot furnace thermal field structure with two-stage thermal insulation cage

A heat insulation and heat insulation cage technology, which is applied in the direction of crystal growth, polycrystalline material growth, chemical instruments and methods, etc., can solve the problem of affecting product quality stability, poor product quality stability, unsatisfactory economy and practicability, etc. problems, to achieve thermal field stability and repeatability, not easy to disturb the airflow disturbance, and the system has remarkable energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

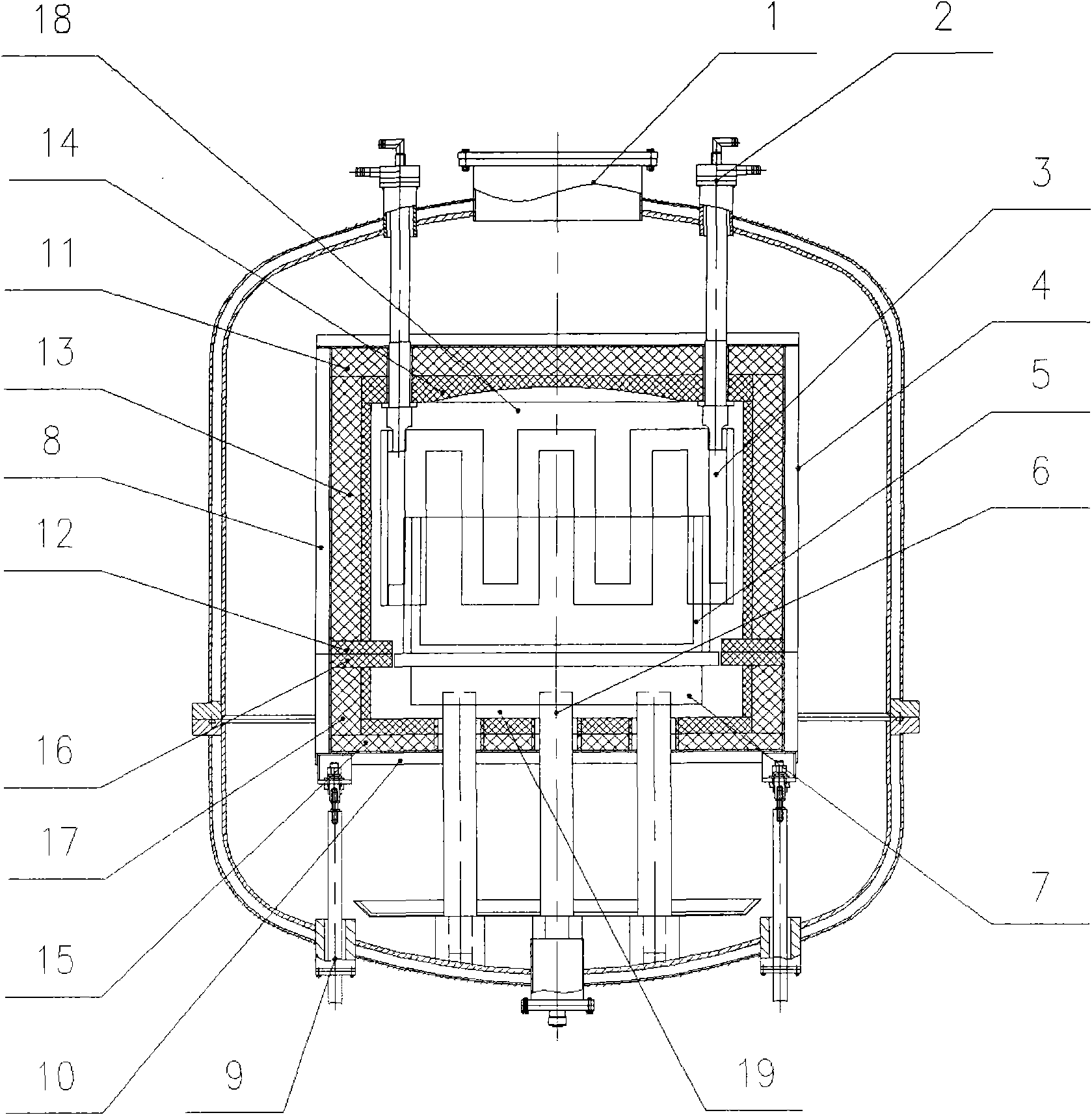

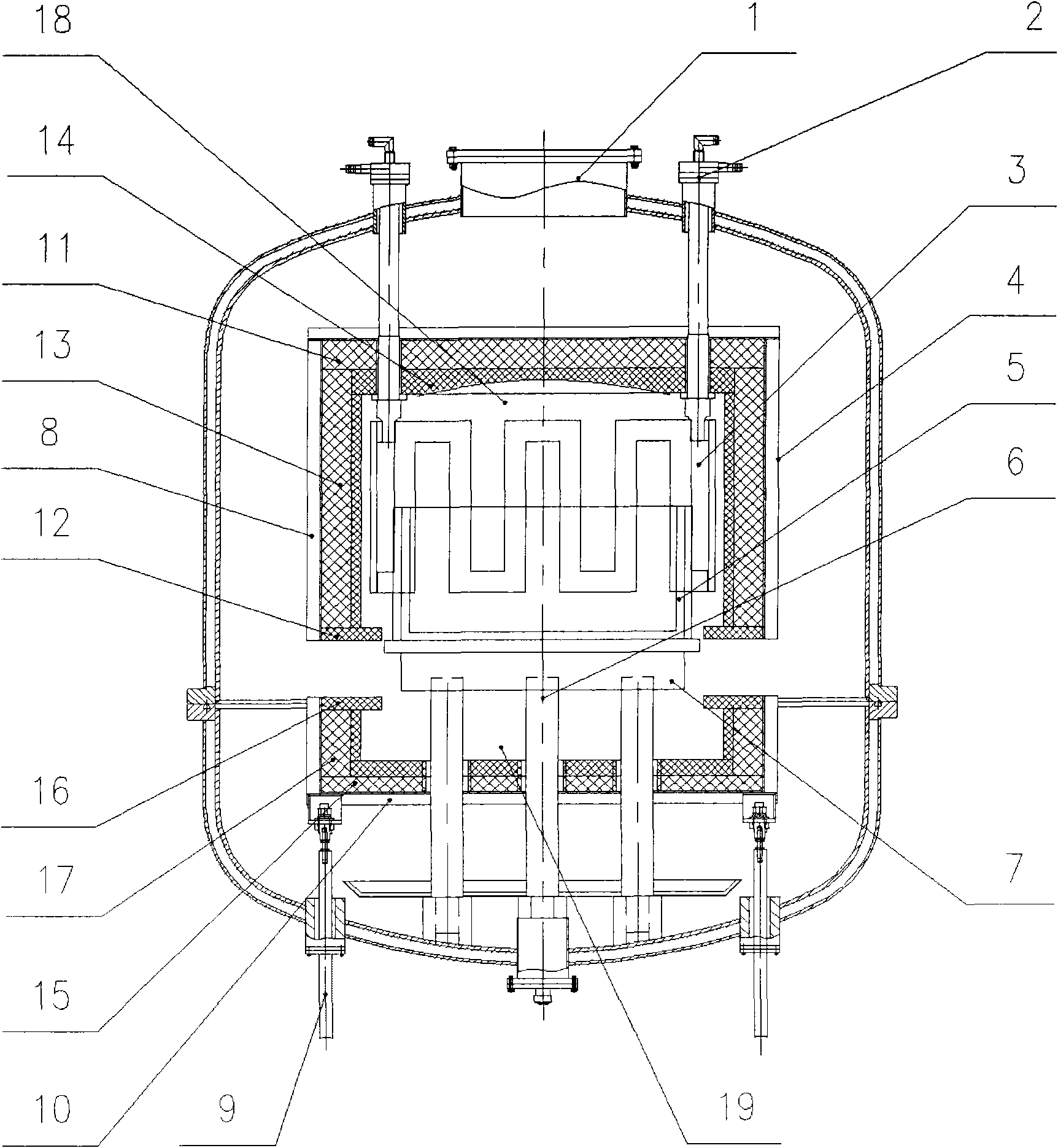

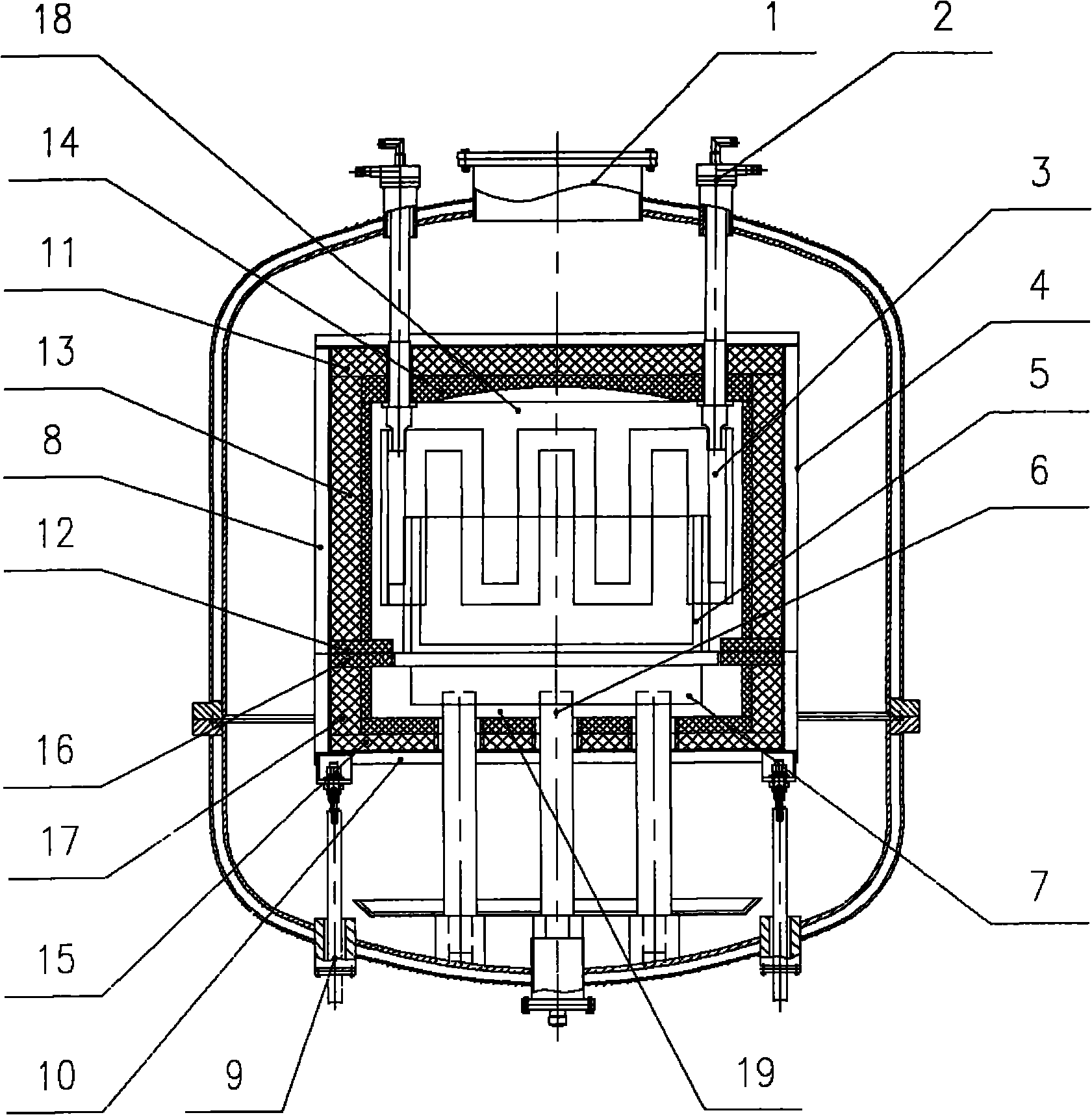

[0016] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0017] exist figure 1 with figure 2 Among them, the thermal field structure of the crystalline silicon ingot furnace with a two-stage heat insulation cage of the present invention mainly includes a furnace body 1, a heating element 3 connected to a water-cooled electrode 2, a heat preservation and heat insulation cage 4, and a crucible 54 and The heat exchange table 7 with the lower pillar 6 is characterized in that the thermal insulation cage 4 is a two-stage type, which consists of an upper heat insulation cage 8 fixed on the top of the furnace body and a lower one fixed on the lifting device 9 at the bottom of the furnace body. The heat insulation cage 10 is combined, wherein: the main body of the upper heat insulation cage 8 is an inverted barrel shape, and the top insulation board 11 and the lower edge are provided with an inward-turned L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com