Heat-resistant cement-based grouting material and preparation method thereof

A grouting material and cement-based technology, applied in the field of building materials, can solve the problems of large aggregate particle size, inapplicability to ordinary grouting projects, and increase material preparation processes, etc., to achieve low porosity, improve volume stability, and reduce volume changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

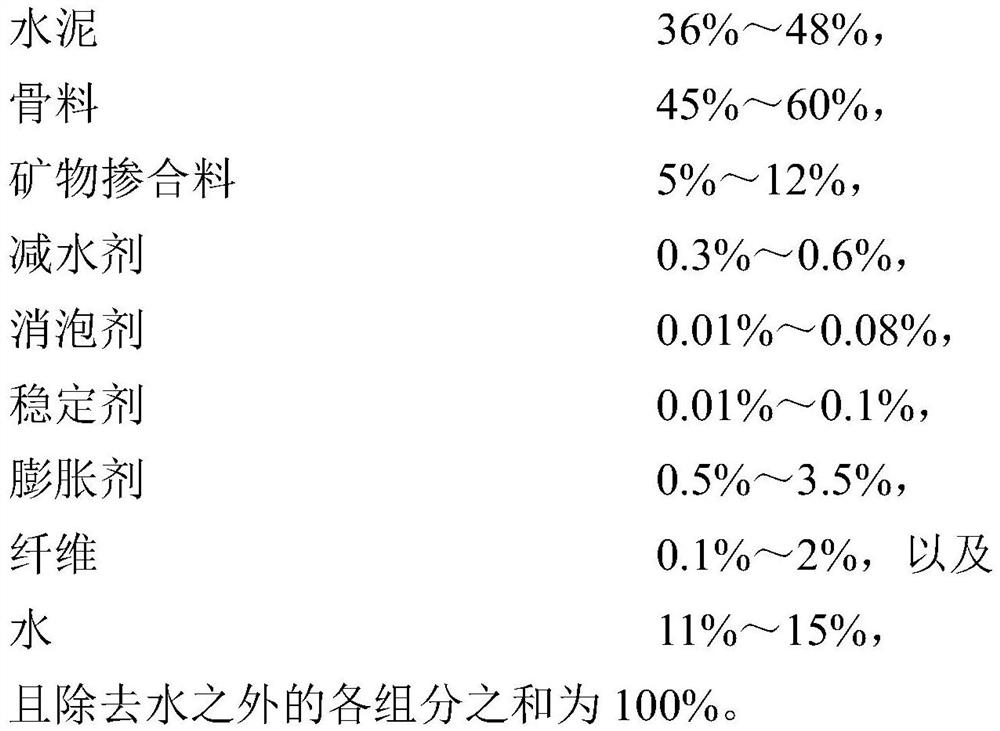

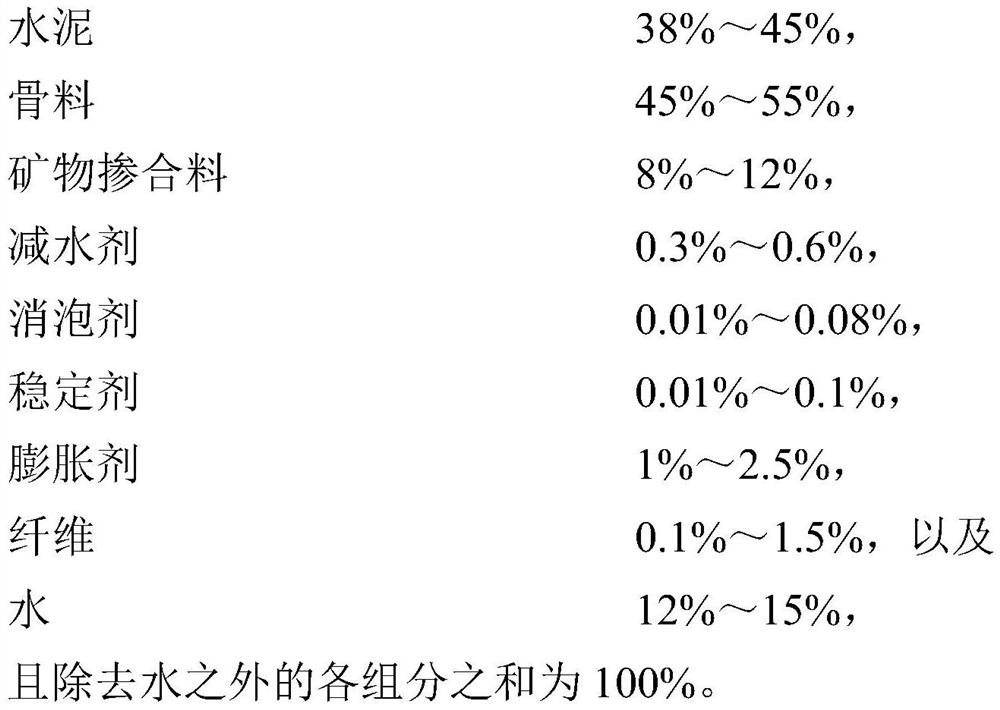

Method used

Image

Examples

Embodiment 1

[0033] CA50-I type aluminate cement 420kg, graded coke gem 490kg, micro silica fume 21kg, finely ground slag powder 48kg, polycarboxylate high-performance water reducer 4.7kg, polyether defoamer 0.3kg, modified bentonite 1kg , molecular sieve 0.2kg, UEA expansion agent 5.5kg, steel fiber 7kg, basalt fiber 2.3kg. Put the above raw materials into a gravity-free mixer and stir for 5 minutes, add 12.5% water after leaving the machine, and stir for 5 minutes to obtain the heat-resistant cement-based grouting material of the present invention. The properties of grouting materials at different ages measured under standard curing conditions are shown in Table 1.

[0034] Table 1 Example 1 grout physical properties

[0035]

[0036]

[0037] The initial fluidity and 30min retention value of the grouting material prepared in this example are both greater than 320mm, showing good fluidity; the 28d compressive strength reaches 121.6MPa, which is high strength; after 20 thermal sh...

Embodiment 2

[0039] P·O4 2.5 Ordinary Portland Cement 390kg, Graded Quartz Sand 510kg, Microsilica Fume 31kg, Ground Slag Powder 50kg, Polycarboxylate High Performance Water Reducer 3.4kg, Organosiloxane Defoamer 0.3kg, Cellulose ether 0.3kg, molecular sieve 0.2kg, UEA expansion agent 11.8kg, steel fiber 3kg. Put the above raw materials into a gravity-free mixer and stir for 5 minutes, add 12.5% water after leaving the machine, and stir for 3 minutes to obtain the heat-resistant cement-based grouting material of the present invention. The properties of grouting materials at different ages measured under standard curing conditions are shown in Table 2.

[0040] Table 2 embodiment 2 grout physical properties

[0041]

[0042] The initial fluidity and 30min retention value of the grouting material prepared in this example are both greater than 320mm, showing good fluidity; the 28d compressive strength reaches 109.6MPa, which is high in strength; after 20 thermal shocks at 300°C, the sur...

Embodiment 3

[0044] P·S·A42.5 slag portland cement 420kg, graded basalt sand 470kg, microsilica fume 17.5kg, finely ground fly ash 70kg, polycarboxylate high-performance water reducer 4.5kg, organosiloxane defoaming Agent 0.5kg, cellulose ether 0.5kg, activated carbon 0.3kg, calcium oxide expansion agent 11.7kg, steel fiber 3.5kg, basalt fiber 1.5kg. Put the above raw materials into a gravity-free mixer and stir for 5 minutes, add 13% water after leaving the machine, and stir for 4 minutes to obtain the heat-resistant cement-based grouting material of the present invention. The properties of grouting materials at different ages measured under standard curing conditions are shown in Table 3.

[0045] Table 3 embodiment 3 grout physical properties

[0046]

[0047] The initial fluidity and 30min fluidity retention value of the grout prepared in this example are both greater than 310mm, indicating good fluidity; the 28d compressive strength reaches 113.4MPa, which is high strength; after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com