Patents

Literature

30results about How to "Self-compacting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foaming concrete made by waste and old concrete and production method thereof and use

InactiveCN101391902ASpeed up the solidificationGuaranteed continuitySolid waste managementCeramicwareUnderground pipelineSubgrade

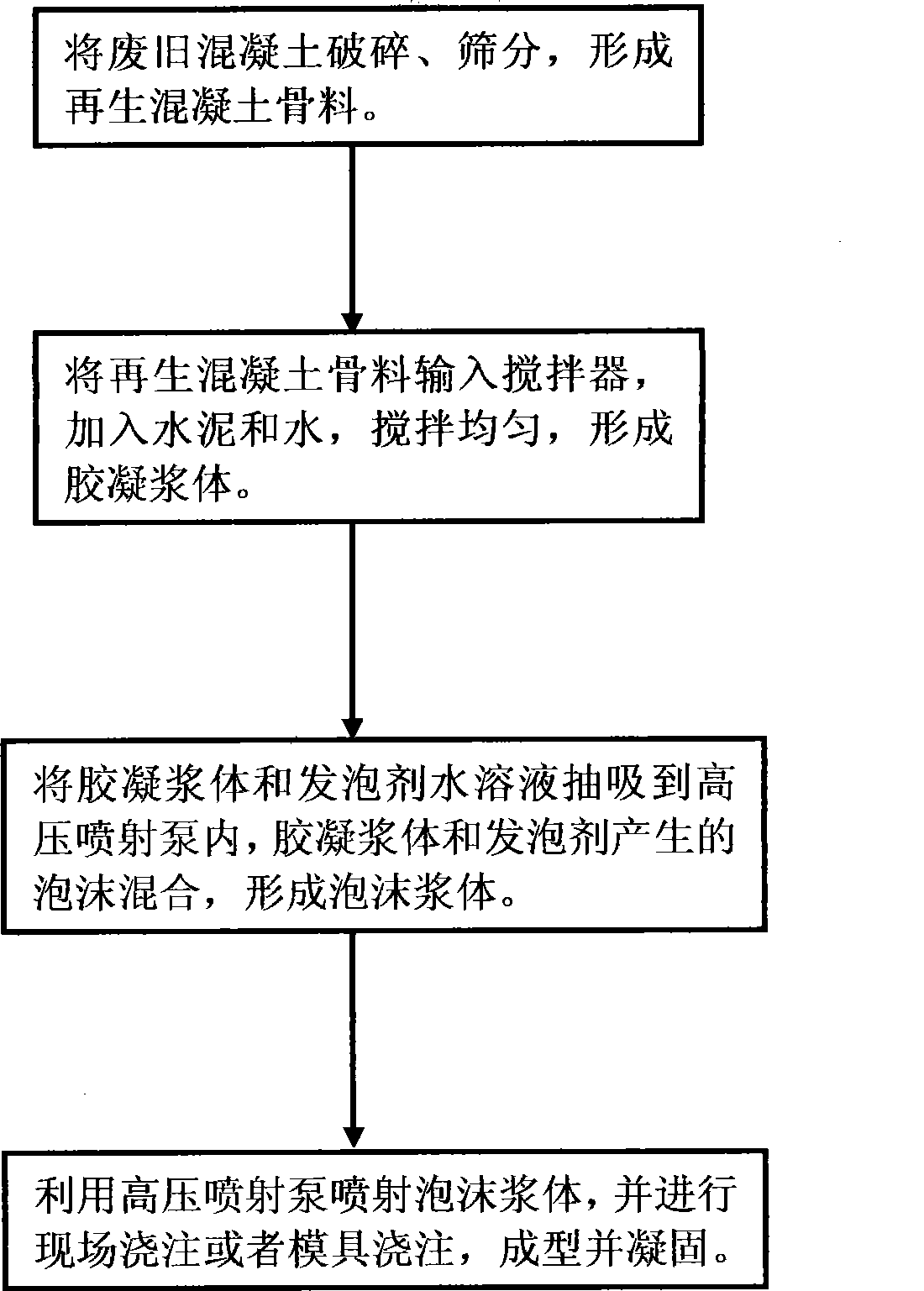

The invention discloses light foaming concrete made by waste concrete, and the production method and application of the foaming concrete. The foaming concrete is formed by the mixing of regenerated foaming concrete aggregate formed after the smashing and screening of the waste concrete, jellous slurry formed by adding concrete, fly ash and water, and foam generated by a foaming agent. After on-spot injection, pouring or mould pouring, the foaming concrete can be used in a plurality of aspects in municipal infrastructure construction such as weak subgrade processing, high filling subgrade, road-widening subgrade, temporary subgrade, various underground pipeline foundation, narrow slot and small clearance space filling, road landslide emergency backfilling, building heat preservation, sound insulation walls and the like. The adoption of the waste concrete for making the foaming concrete has the advantages of utilizing the waste, being environment-friendly, saving energy and having low cost, and the like, and the produced foaming concrete has a plurality of good performances such as light weight, no lateral confinement compression resistance, self-compaction and vibro-free property, and the like.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

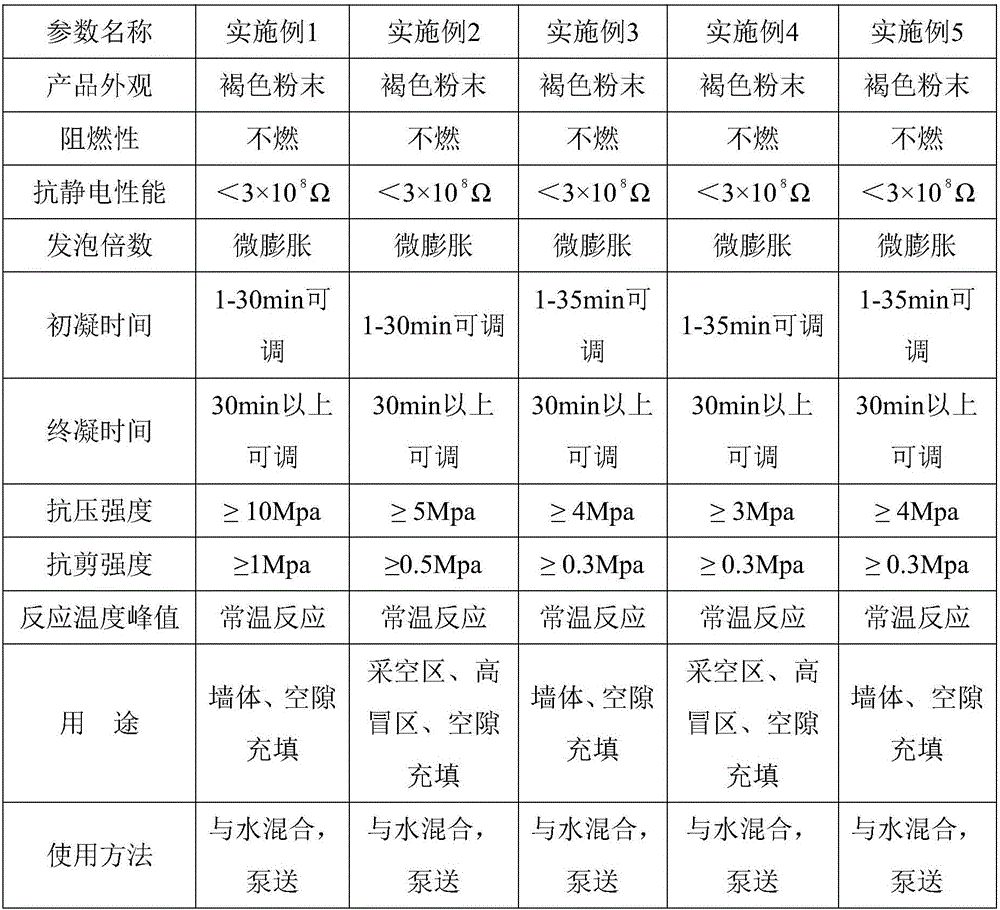

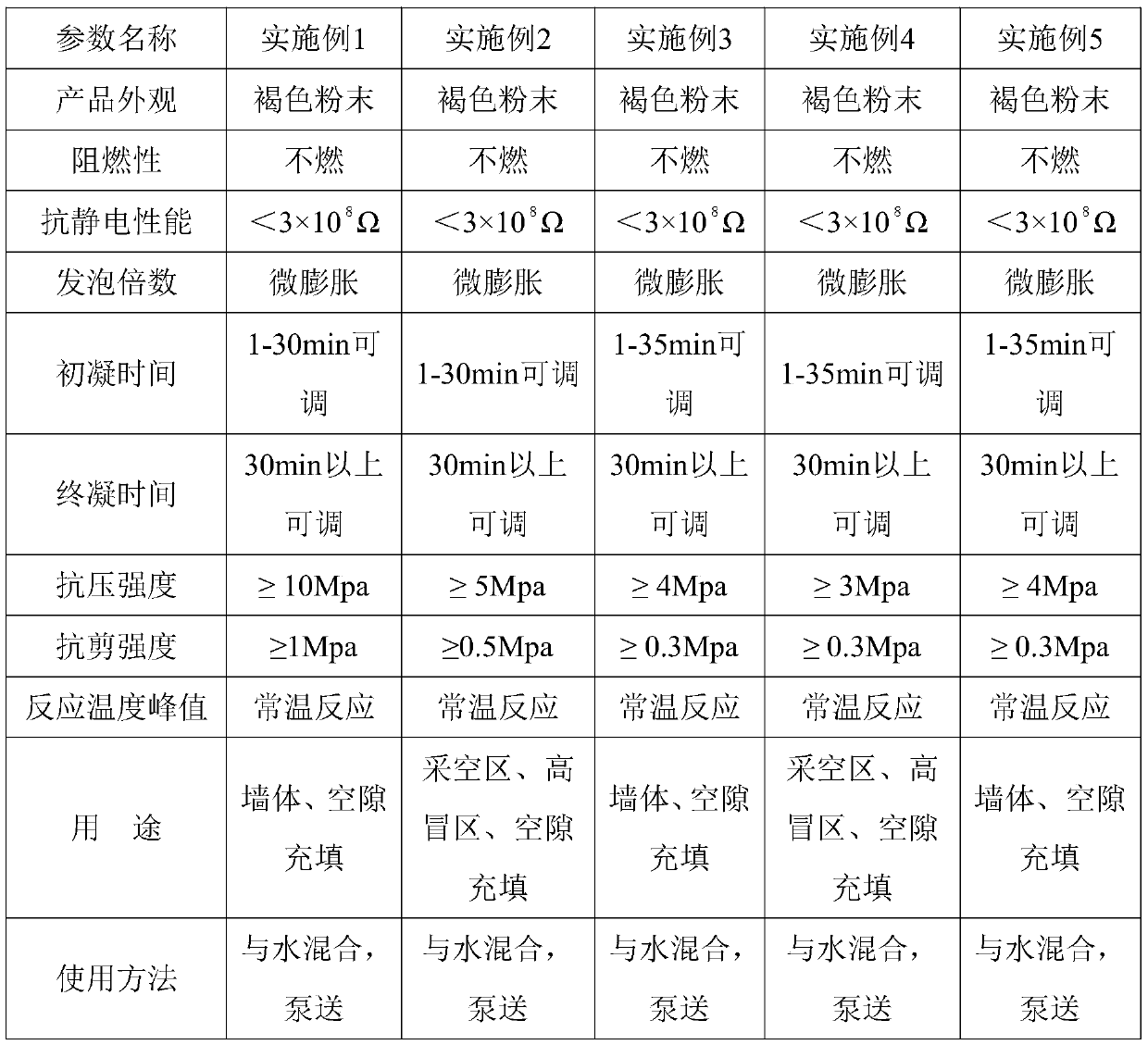

Mineral inorganic superfine foamed filling material as well as preparation method and application method of mineral inorganic superfine foamed filling material

ActiveCN106747636ANon-combustibleAntistaticSolid waste managementCeramicwareSodium BentoniteFoaming agent

The invention provides a mineral inorganic superfine foamed filling material. The mineral inorganic superfine foamed filling material is prepared from the following raw materials in parts by weight: 8 to 18 parts of sulphoaluminate cement, 25 to 40 parts of bentonite, 3 to 10 parts of pearlite, 30 to 45 parts of fly ash, 3 to 8 parts of a foaming agent and 0.3 to 1 part of a water reducing agent. The mineral inorganic superfine foamed filling material provided by the invention is used for reinforcing coal mine crushed gangues and loose coal-rock masses and filling a goaf, a roof falling zone and a roadside, and has the characteristics of capability of pumping in a long distance, rapid condensation, uneasiness of cracking, greenness and environment friendliness. The invention further provides a preparation method and an application method of the mineral inorganic superfine foamed filling material.

Owner:ANHUI JIATAI COAL MINING TECH

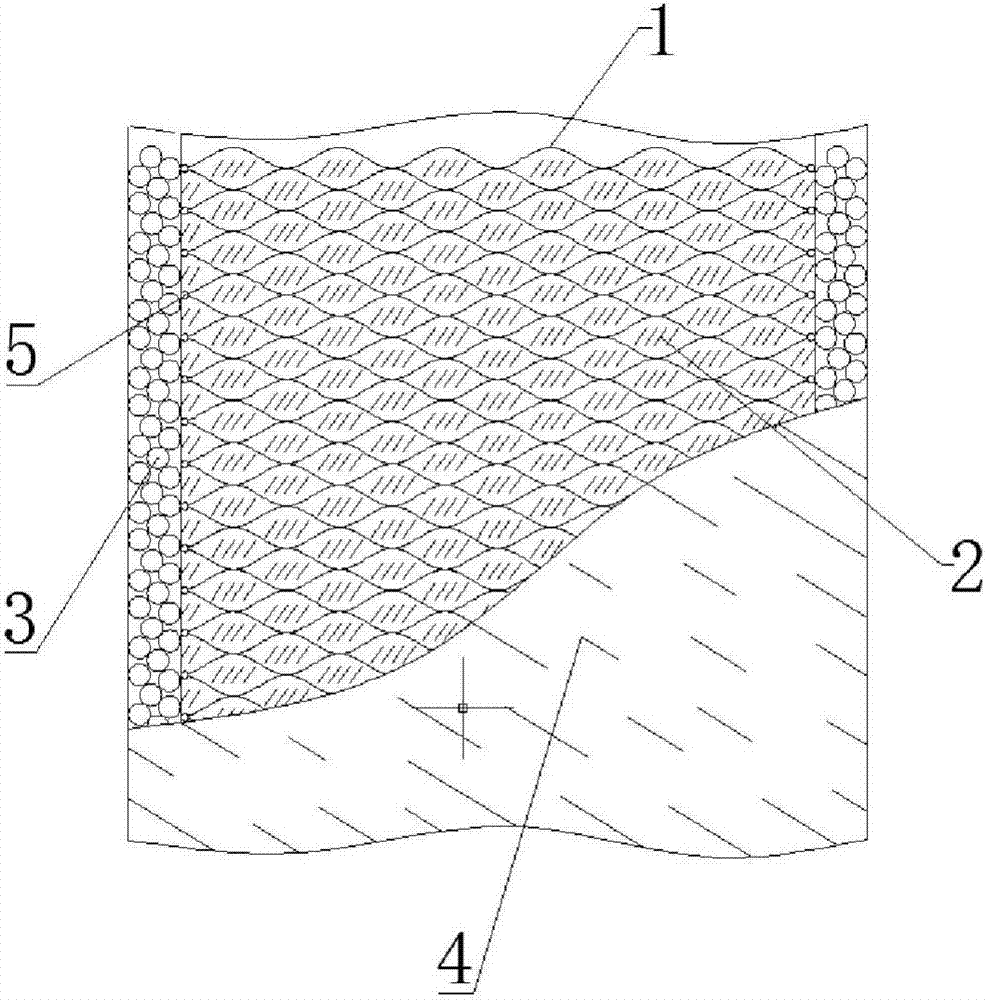

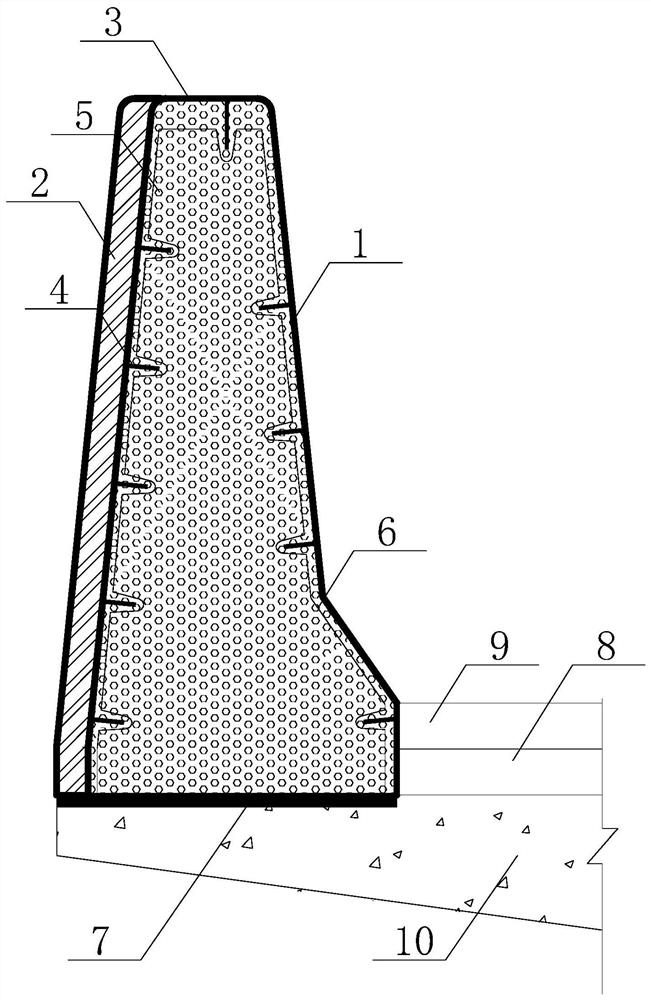

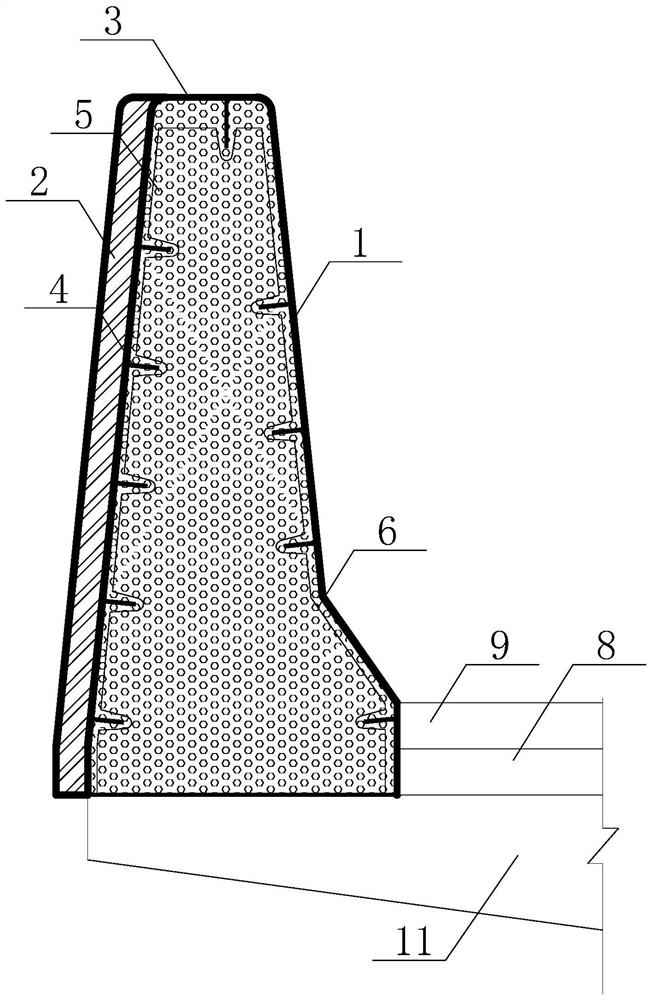

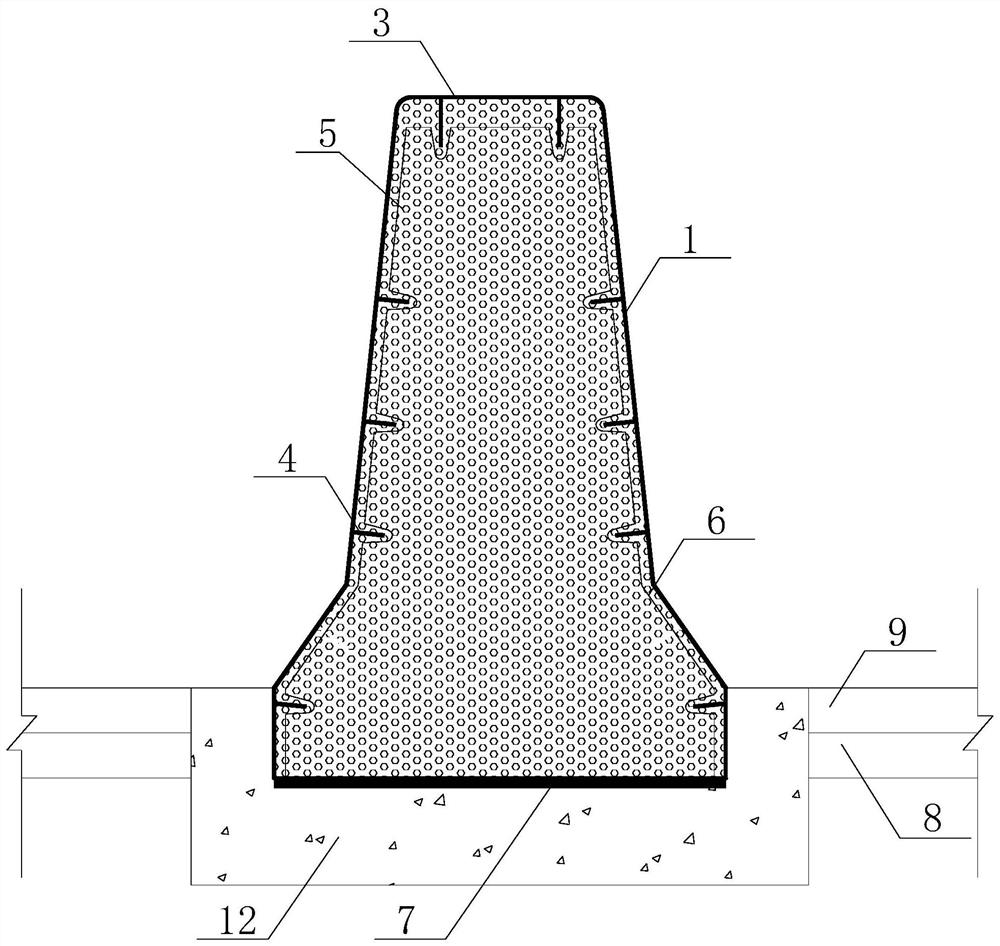

Earthwork standard room bar-adding cellular concrete light roadbed filling structure and method thereof

InactiveCN107165013AImprove liquiditySelf-compactingPaving gutters/kerbsCeramicwareFoam concreteEngineering

The invention discloses an earthwork standard room bar-adding cellular concrete light roadbed filling structure and method thereof, and belongs to the technical field of design and construction in roadbed project. A roadbed structure of the invention adopts high-strength earthwork standard room bar adding, and then is filled by light cellular concrete. The construction method comprises the following steps of excavating and leveling an original foundation; tensioning and fixing an earthwork standard room; pouring and filling cellular concrete materials; arranging a drainage ditch; and arranging geotechnical cloth. The roadbed structure adopts the filling of the earthwork standard room bar-adding cellular concrete, has the characteristics of being high in base bending and pulling resistance strength and good in durability, the occurrence of large settlement deflection and deformation is avoided, and meanwhile by using the earthwork standard room bar-adding, the strength and integrity of the base are further enhanced, the road surface structure damage from lower to uppwer caused by the cracking and crushing of the materials is avoided, and the roadbed structure is suitable for roadbed engineering construction of all levels of roads, especially for the geological conditions of foundations with low bearing capacity.

Owner:SOUTHEAST UNIV

Anti-crack pumping concrete, and preparation method and pumping method thereof

InactiveCN110746159AChoose simpleWide variety of sourcesBuilding material handlingSuperplasticizerCarboxylic acid

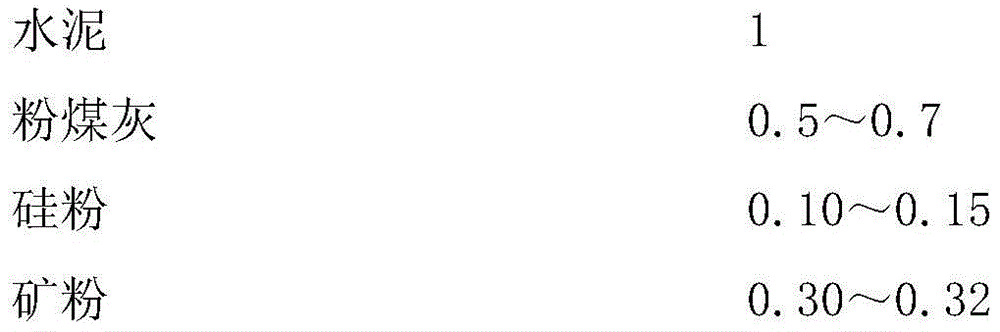

The invention discloses an anti-crack pumping concrete, and a preparation method and a pumping method thereof, and belongs to the field of concrete preparation. The anti-crack pumping concrete comprises, by weight, 380-420 parts of cement, 1050-1210 parts of coarse aggregates, 630-675 parts of fine aggregates, 58-72 parts of fly ash, 40-78 parts of S95-grade mineral powder, 45-60 parts of silica fume, 0.8-5 parts of a polypropylene fiber, 12.5-15.1 parts of a polycarboxylate superplasticizer and 128-136 parts of water. The water-cement ratio is controlled to be 0.28-0.34; the water-binder ratio is controlled to be 0.23-0.27, the fly ash accounts for 10-13% of the total amount of all cementing materials, the mineral powder accounts for 7-14% of the total amount of all the cementing materials, the silica fume accounts for 7-11% of the total amount of all the cementing materials, the ratio of the fly ash to the mineral powder is controlled to be 1.2-1.68, and the sand rate is controlled to be 0.3-0.39. The anti-cracking pumping concrete has a high strength, and can meet the pumping requirement of 100 m superhigh-rise building construction.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Concrete material for high-performance structural engineering and preparation method and application thereof

InactiveCN106220089AImprove liquidityEasy constructionBuilding material handlingFiberReinforced concrete

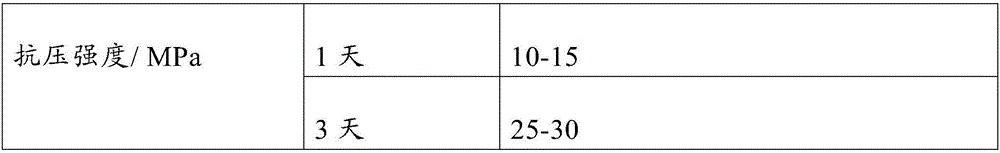

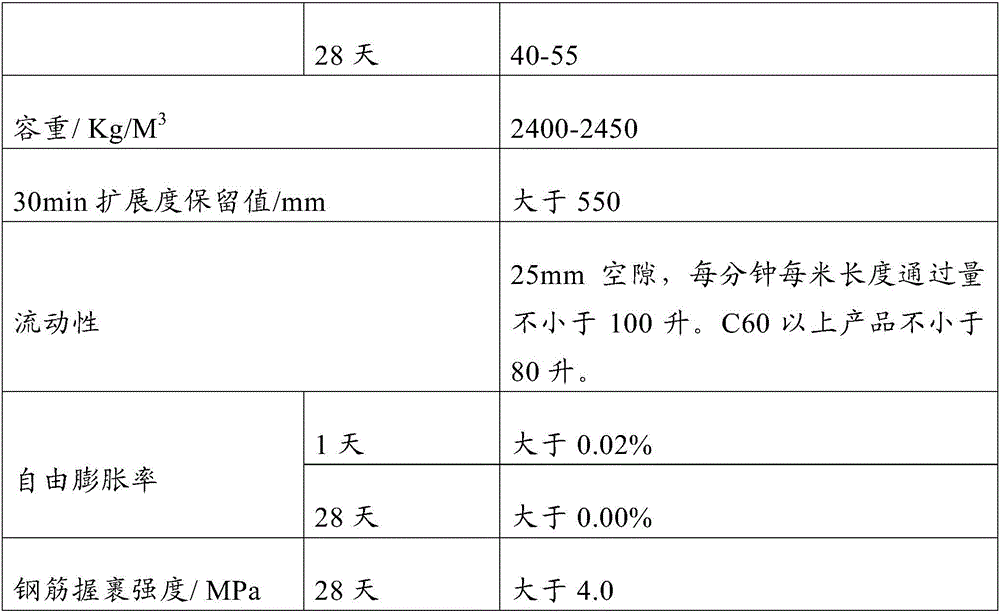

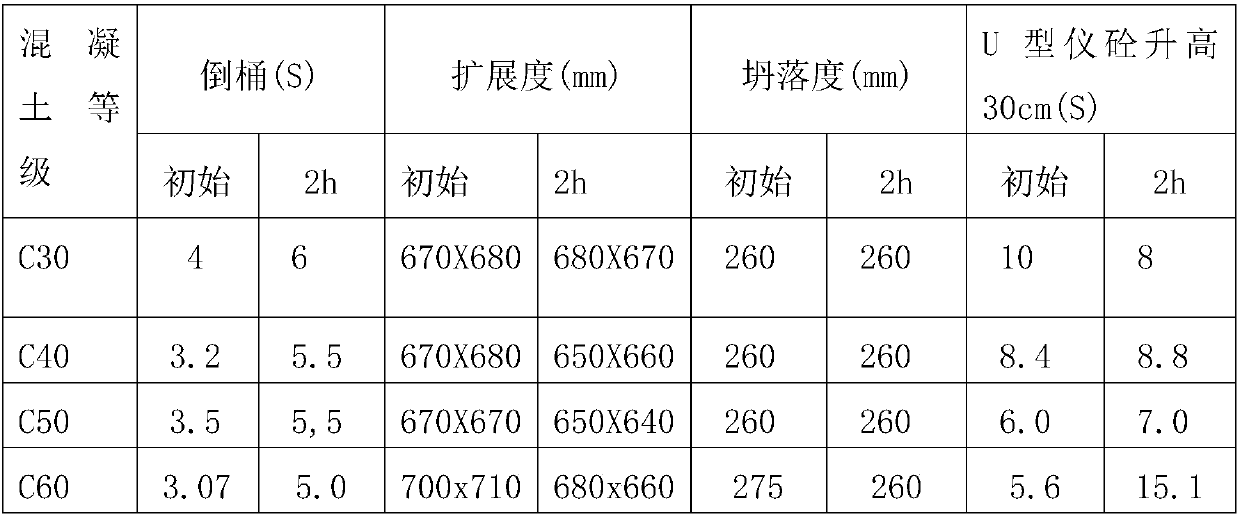

The invention provides a concrete material for high-performance structural engineering and a preparation method and application thereof. The concrete material is prepared from cement with concentration of 400-900 Kg / m<3>, coarse aggregate with concentration of 300-950 Kg / m<3>, fine aggregate with concentration of 500-1050 Kg / m<3>, shrinkage-compensating admixture with concentration of 0-100 Kg / m<3>, polymeric additives with concentration of 1-15 Kg / m<3>, silica fume with concentration of 0-65 Kg / m<3> and fiber with concentration of 0.5-2.5 Kg / m<3>, wherein the grain size of the coarse aggregate is 5-16 mm, the grain size of the fine aggregate is smaller than 5 mm, the water contents of all the raw materials are smaller than 1.5%, and the water addition amount accounts for 7-11% of the amount of the dry materials in the use process. The preparation method of the concrete material includes the following steps of selecting the raw materials according to the compositions and consumption, conducting mechanical stirring for 3 min or longer, and conducting waterproof and damp-roof packaging. The concrete material is suitable for concrete pouring of reinforced concrete beam-column joints and reinforced steel bar dense areas in structural engineering, concrete cast-in-place partial pouring and tamping of prefabricated structures, reconstruction and expansion in decoration process, pouring of other engineering structures and the like.

Owner:SHANGHAI MEICHUANG ARCHITECTURAL MATERIALS

Manufacturing method of artificial lightweight aggregate or super lightweight aggregate multifunctional concrete

The invention relates to a manufacturing method of artificial lightweight aggregate or super lightweight aggregate multifunctional concrete and belongs to the technical field of novel concrete materials, environmental engineering and construction. Firstly, a special additive C for preparing the artificial lightweight aggregate or super lightweight aggregate multifunctional concrete is manufactured, a shrinkage restraining additive D is manufactured, after cement, mineral powder, coal ash, microbeads, silica powder, water, glass beads, river sand and other materials are weighed in proportion, the materials are mixed according to the process requirement, and the artificial lightweight aggregate or super lightweight aggregate multifunctional concrete is obtained. According to the method, the multifunctional concrete is manufactured from domestic existing concrete raw materials, industrial residues and other materials, and the product has the functions of self-compaction, self-maintenance, low hydration heat, low shrinkage, high durability and high plasticity retention, and can be applied to constructional engineering, civil engineering, traffic engineering and the like. The manufacturing method has the advantages that construction is convenient, quality is easy to guarantee, management is easy and convenient, and cost is low, energy and resources are saved, and the requirements of environmental protection are met.

Owner:冯乃谦 +2

Harmless recycling method for heavy metal in domestic garbage power generation ash

The invention relates to a method for utilizing domestic garbage power generation fly ash and slag and waste glass abrasive powder as main raw materials to fire ceramsite. According to the method, heavy metal elements in the ash is cured by high-temperature firing; the heavy metal elements are sprayed on the surface of ceramsite by a hydrophobic emulsion, so that ceramsite holes are sealed, the surface is hydrophobic, and outward diffusion and permeation of residual heavy metal elements are prevented; when the ceramiste is utilized to prepare multifunctional concrete, the ceramsite is furtherwrapped by cement mortar. Detection of an environmental protection department shows that the heavy metal content in the cement mortar can meet a three-level soil quality requirement in GB15618-1995 and meet a HJ / T298-2007 hazardous waste identification technique requirement; heavy metal elements in domestic garbage power generation fly ash and slag become harmless; the multifunctional concrete produced from the ceramsite can be applied to the related fields of construction; the domestic garbage power generation fly ash and slag become useful resources.

Owner:冯乃谦 +1

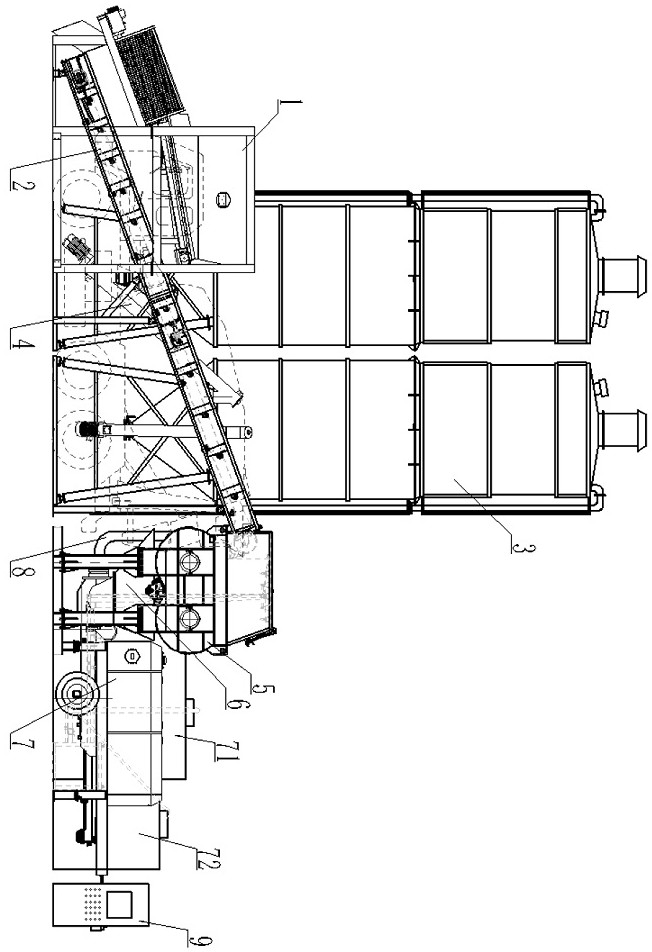

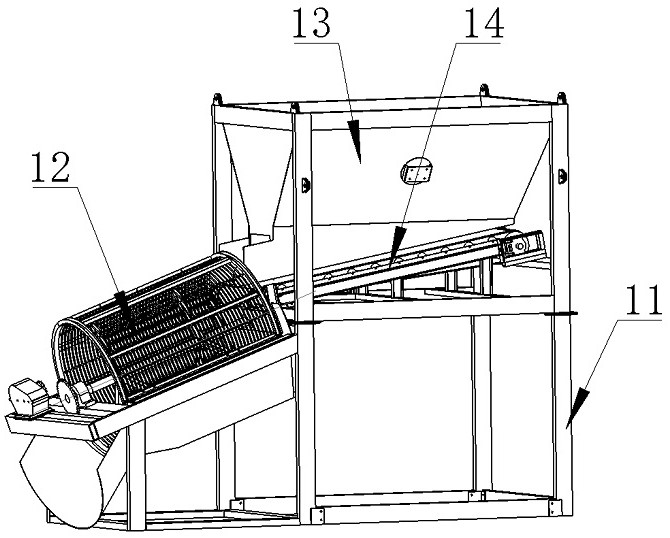

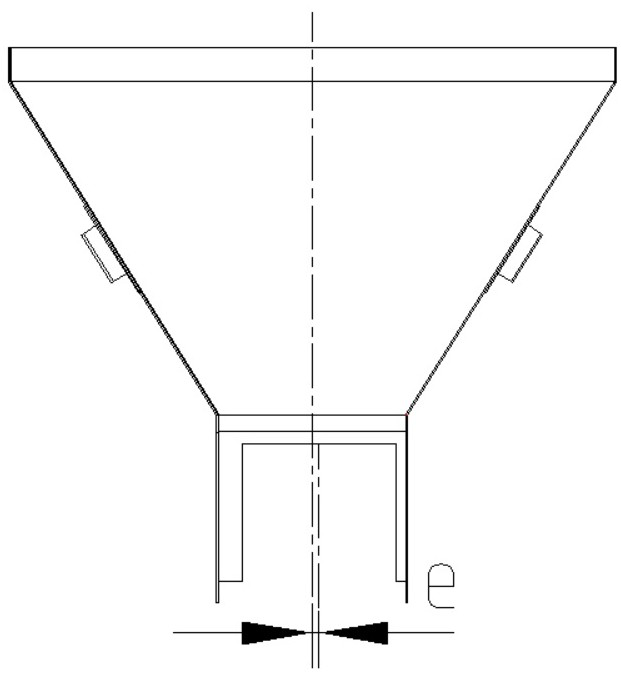

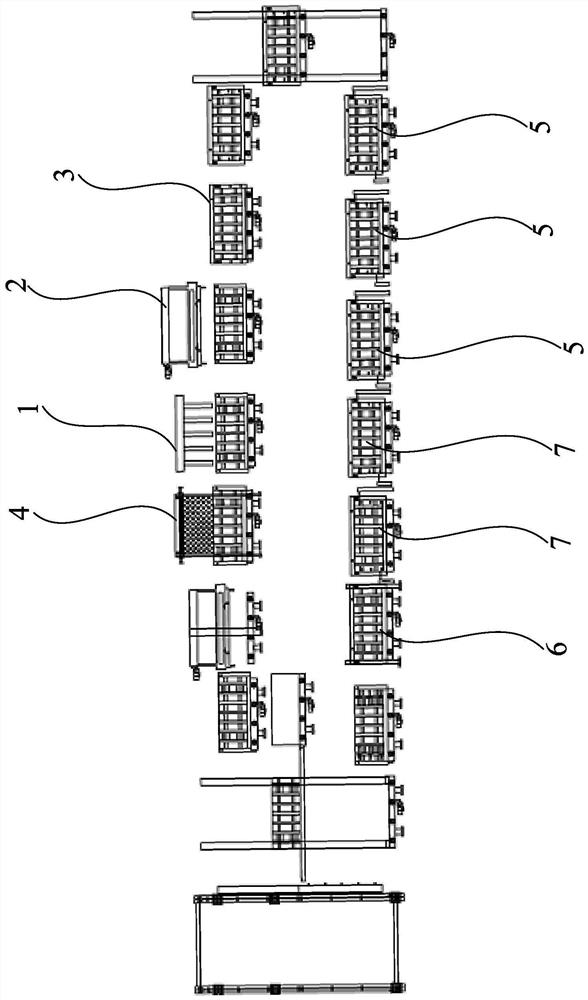

Complete equipment for preparing liquefied consolidated soil from waste residue soil and construction method of complete equipment

PendingCN112776182AWell mixedQuality improvementIngredients weighing apparatusCement mixing apparatusProcess engineeringMaterial storage

The invention discloses complete equipment for preparing liquefied consolidated soil from waste residue soil and a construction method of the complete equipment. The complete equipment comprises a screening device, an ingredient conveying device, a material storage device, a material conveying device, a stirring device, a finished product material temporary storage bin, a pumping device, a finished product material conveying pump and a control device. The discharging end of the screening device is connected with the feeding end of the ingredient conveying device. The discharging ends of the ingredient conveying device and the pumping device are both connected with the feeding end of the stirring device, the discharging end of the stirring device is connected with a feeding port of the finished product material temporary storage bin, a discharging port of the material storage device is connected with a feeding port of the material conveying device, and a discharging port of the material conveying device is connected with the ingredient conveying device. The finished product material conveying pump is connected with a discharging port of the finished product material temporary storage bin through a pipeline, and the screening device and the ingredient conveying device are arranged in a radial offset mode. In general, the complete equipment for preparing the liquefied consolidated soil from the waste residue soil and the construction method of the complete equipment have the advantages of being convenient to use, accurate and stable in metering, small in operation difficulty, short in construction period and good in construction quality.

Owner:河南绿岩工程科技有限公司

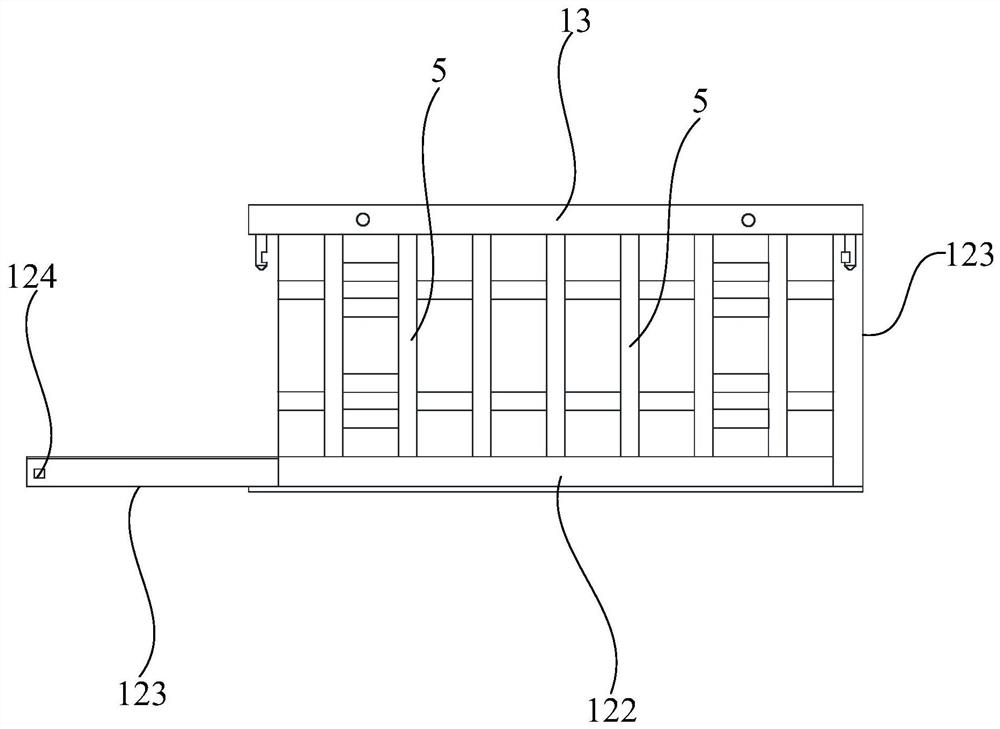

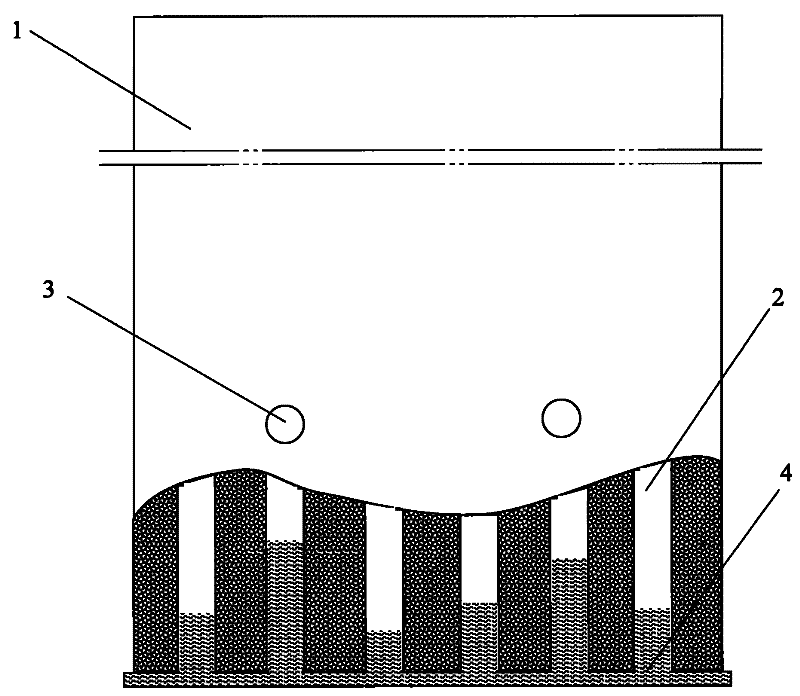

Production equipment for A-grade fireproof insulation board

PendingCN112959474ASelf-compactingIncrease productivityMould separation apparatusFeeding arrangmentsEconomic benefitsProcess engineering

The invention discloses production equipment for an A-grade fireproof insulation board. The production equipment comprises a material injection unit, an upper cover hoisting device, a pressurizing and locking unit, wherein the material injection unit is used for placing a lower die of a die and putting a raw material composition into the lower die. The upper cover hoisting device is positioned at the downstream of the material injection unit and is used for connecting an upper cover of the die to the lower die, so that a die space is formed between the lower die and the upper cover. The pressurizing and locking unit is located on the downstream of the upper cover hoisting device and used for applying acting force to side dies on the two sides of the die, so that the two side dies move in the direction close to each other, and the pressurizing and locking unit is used for limiting the two side dies to move in the direction away from each other. Vertical material injection is beneficial to self-compaction of materials in the die, so that the production efficiency is improved, and the occupied production field is saved to the maximum extent; and the potential safety hazard existing in manual operation and the potential safety hazard of uncontrollable product quality are reduced, the production efficiency is further improved, and the yield and the economic benefit are improved.

Owner:上海圣奎机械科技有限公司

Mine filling material and preparation method thereof

The invention provides a mine filling material and a preparation method thereof. The mine filling material is prepared from, by weight, 90-95 parts of a curing agent, 10-25 parts of sludge, 1-5 partsof construction waste particles, 0.5-2 parts of municipal waste particles, 0.1-0.5 part of a rheology modifier, 0.1-0.5 part of a thickening time control agent and 0.1-0.5 part of a defoaming agent; and the curing agent comprises 25-35 parts of ettringite, 25-35 parts of calcium silicate clinker, 15-25 parts of calcium sulfate, 15-20 parts of quick lime and 0.5-1 part of aluminum powder. The minefilling material can be stably conveyed into a filling mine for a long distance, the safety of a filling system can be guaranteed in the conveying process, condensation and segregation are avoided inthe conveying process, meanwhile, after a filling slurry is conveyed into a target mine, rapid condensation can be achieved, the strength is guaranteed, ecological environment treatment is achieved, and meanwhile waste materials are comprehensively recycled.

Owner:GUYAN TECH DEV CO LTD

A method for producing multi-functional concrete by utilizing domestic waste power generation waste slag

Owner:冯乃谦 +3

Concrete ingredient and fast hardening concrete

The invention relates to a concrete ingredient and fast hardening concrete prepared by mixing the concrete ingredient, which belong to the field of materials in construction engineering, and are mainly used in masonry or rush repair of the periphery of inspection wells on urban roads. The concrete ingredient includes sulfur aluminum cement, coarse aggregate, fine aggregate, a reinforcing material, an enhancing material, a coloring material, an expanding agent, a water reducing agent and an accelerating agent. In the concrete prepared by mixing the concrete ingredient, the weight ratio of the fast hardening concrete ingredient to water is 1:0.12-0.13. The concrete prepared by mixing the concrete ingredient has the properties of self-leveling, super early strength, high strength, micro expansion, resistance to shrinking, penetration, wear and ageing, and the like.

Owner:TIANJIN JUSHI TECH DEV

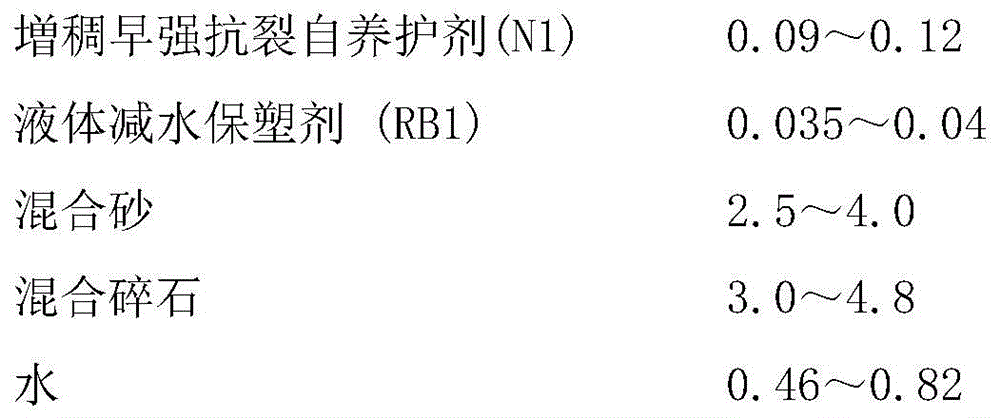

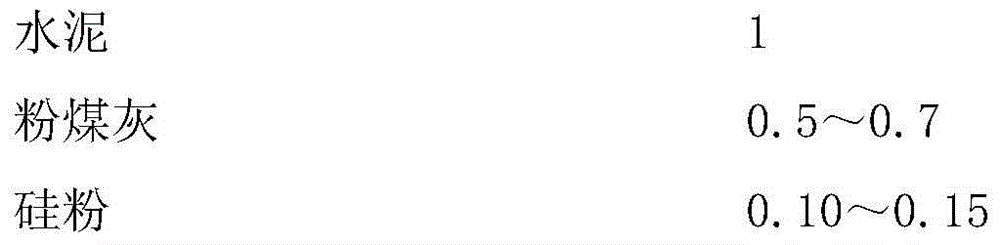

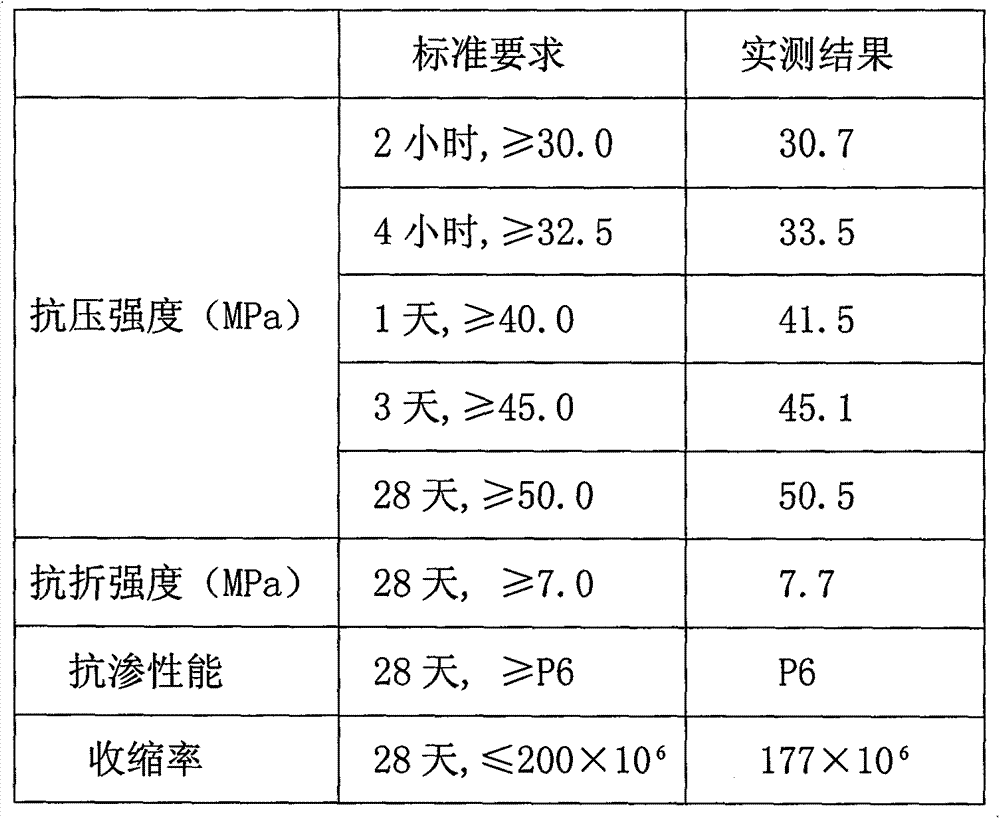

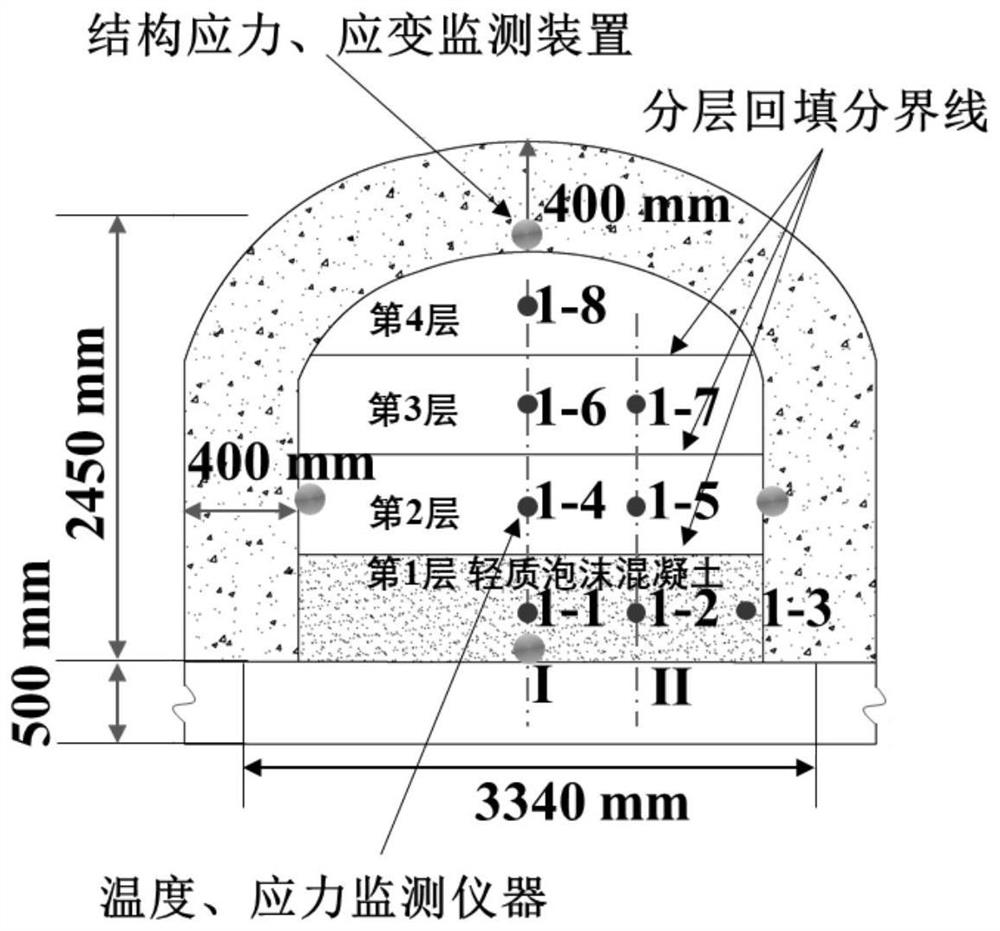

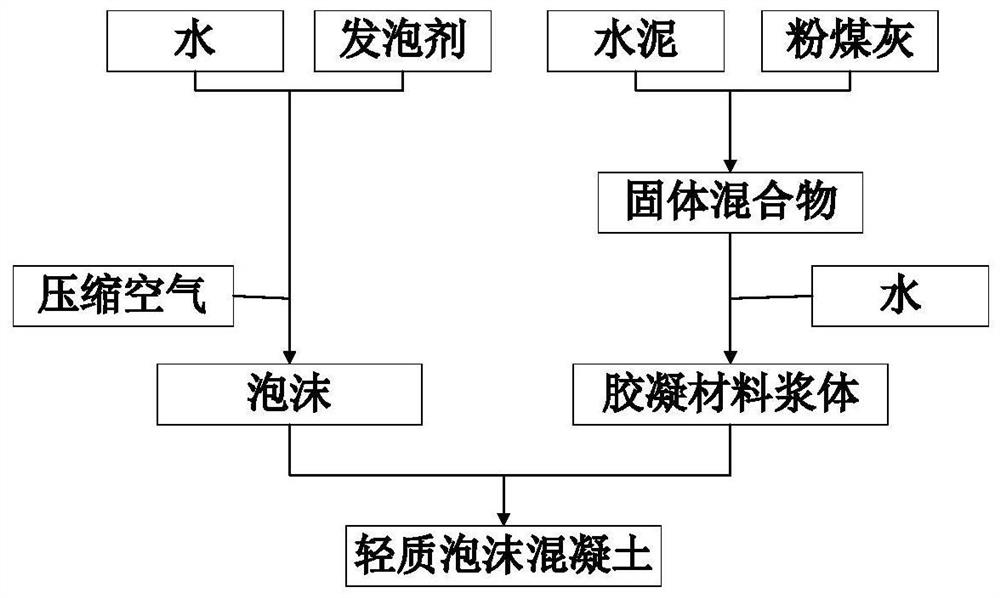

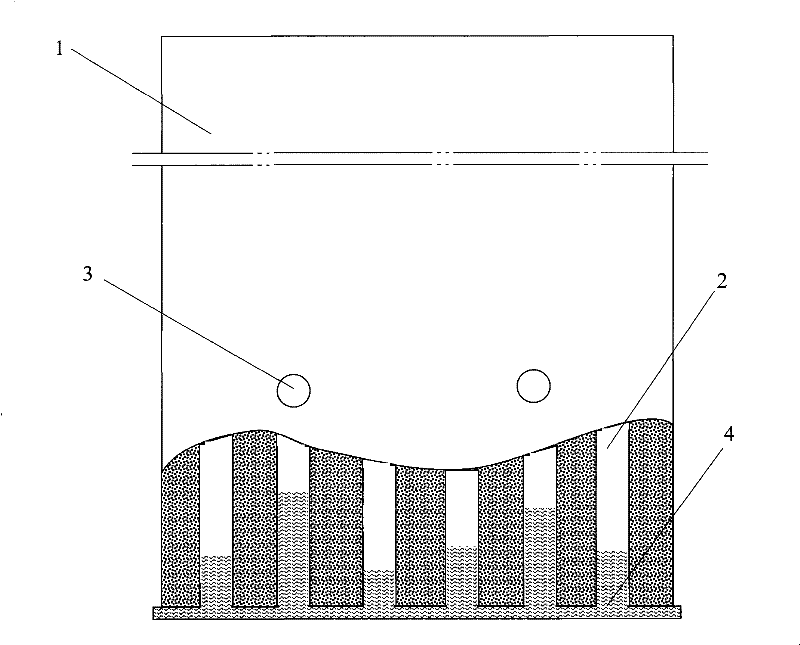

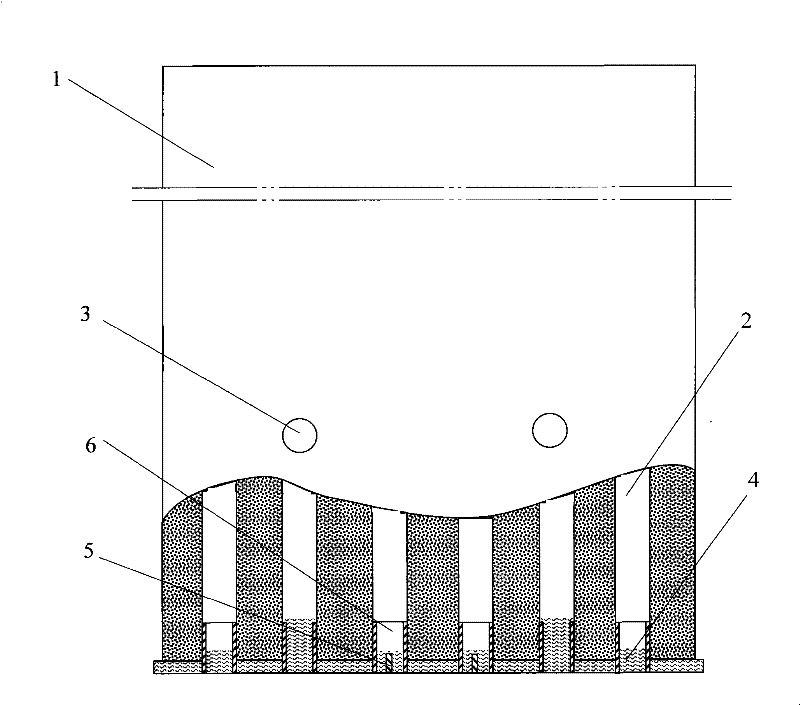

Method for backfilling light foam concrete in urban abandoned underground space in soft soil area

The invention discloses a method for backfilling light foam concrete in an urban abandoned underground space in a soft soil area. The method comprises the following steps that (1) according to the surrounding environment and building conditions of the urban abandoned underground space to be backfilled, a water pumping-backfilling monitoring scheme is formulated, and horizontal displacement and settlement monitoring points are arranged; (2) accumulated water in a project is slowly pumped and drained, internal sundries are cleared, and an internal structure stress and strain monitoring device and a temperature and stress monitoring instrument for the light foam concrete in the backfilling process are arranged; (3) the density rho of the light foam concrete for backfilling is converted through an equivalent load method rho whw = rho h, and light foam concrete with the density grade is prepared; (4) according to a layering and blocking backfilling principle, the waste underground space are divided into layers and blocks, the light foam concrete is sequentially pumped from the interior of a project to an opening for backfilling in a layered and blocked mode, samples are reserved to test the physical and mechanical properties of light foam concrete samples in each backfilling stage until the space is densely backfilled; and (5) the backfilling effect is checked by adopting a coring and geophysical prospecting method.

Owner:TONGJI UNIV

Construction method of cast-in-situ stiff piles for foundation pit supporting

The invention discloses a construction method of cast-in-situ stiff piles for foundation pit supporting. The method comprises the following construction steps: paying off and locating; after a construction platform is laid, drilling pile holes by a spiral drilling machine, wherein the pile holes have the apertures of 350mm, and when the pile holes are drilled, the maximum drilling amount of every time is less than or equal to 500mm, the deviation between the center of a drill bit and each pile position is less than or equal to 5cm, and the pile verticality deviation is less than or equal to 0.5%. After the construction method is adopted, the utilization rate of a reinforcing steel bar of a pile body is improved, the construction technology is simplified, the cost is lowered, and the time limit for a project is shortened.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

High-early-strength freeze-thaw resistant spraying material and preparation method thereof

The invention discloses a high-early-strength freeze-thaw resistant spraying material and a preparation method thereof. The high-early-strength freeze-thaw resistant spraying material is prepared fromthe following components in parts by weight: 100 parts of spraying dry powder, 3-5 parts of hardening accelerator and 10-15 parts of water, wherein the hardening accelerator adopts aluminium oxide asa main component; and the spraying dry powder is prepared from the following components in percentage by mass: 25%-35% of a cementing material, 35%-50% of natural grading medium sand, 15%-20% of stone, 5%-15% of redispersible latex powder, 0.1%-0.3% of polycarboxylate superplasticizer, 0.02%-0.1% of polypropylene staple fiber, and 0.01%-0.2% of polymer additive. The spraying material has high workability, stable performance, sag resistance and trowelling performance, and has rapid hardening and early strength effects after spraying construction, the preparation process is simple, the construction is convenient and efficient, and the spraying material is specially used for building construction materials of snowmobiles, sleds and racing tracks.

Owner:上海宝冶工程技术有限公司

Method for Harmless and Recycling of Heavy Metals in Ashes of Domestic Garbage Power Generation

The invention relates to a method for utilizing domestic garbage power generation fly ash and slag and waste glass abrasive powder as main raw materials to fire ceramsite. According to the method, heavy metal elements in the ash is cured by high-temperature firing; the heavy metal elements are sprayed on the surface of ceramsite by a hydrophobic emulsion, so that ceramsite holes are sealed, the surface is hydrophobic, and outward diffusion and permeation of residual heavy metal elements are prevented; when the ceramiste is utilized to prepare multifunctional concrete, the ceramsite is furtherwrapped by cement mortar. Detection of an environmental protection department shows that the heavy metal content in the cement mortar can meet a three-level soil quality requirement in GB15618-1995 and meet a HJ / T298-2007 hazardous waste identification technique requirement; heavy metal elements in domestic garbage power generation fly ash and slag become harmless; the multifunctional concrete produced from the ceramsite can be applied to the related fields of construction; the domestic garbage power generation fly ash and slag become useful resources.

Owner:冯乃谦 +1

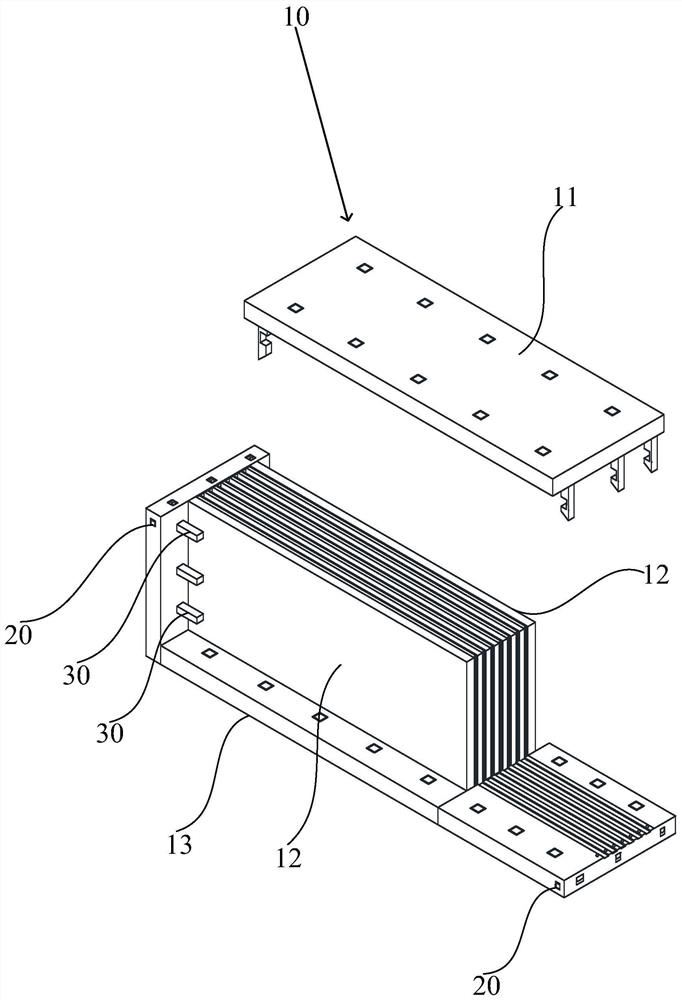

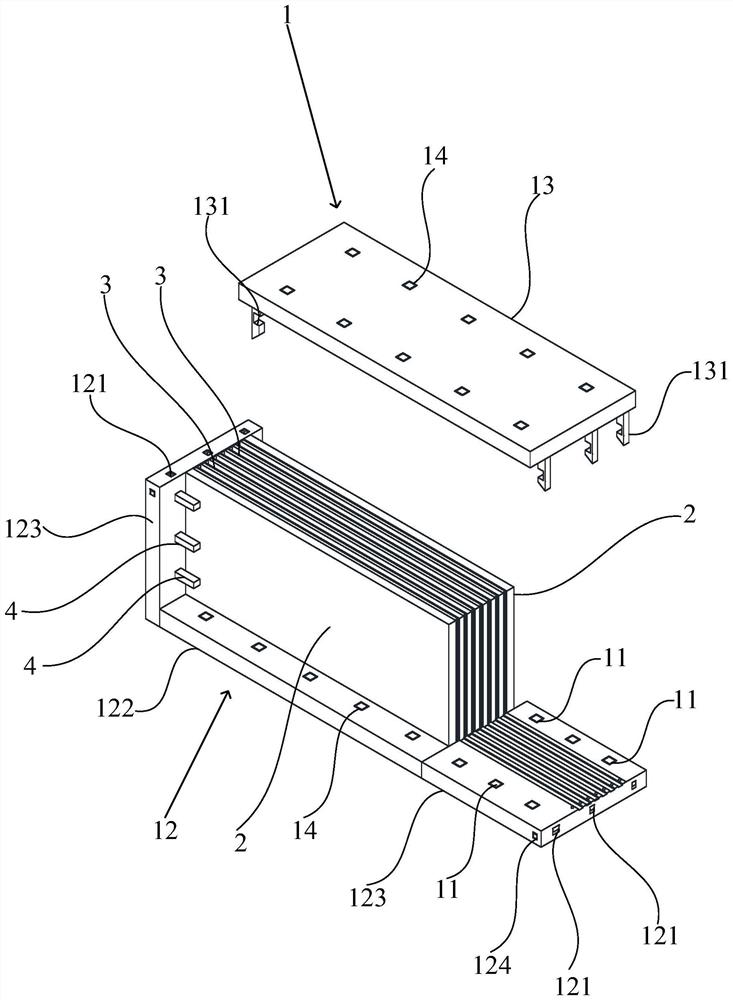

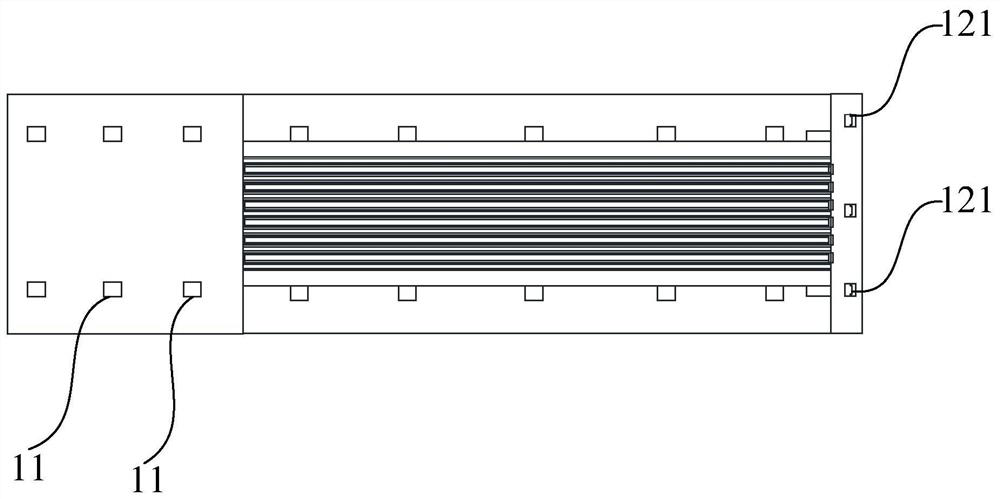

Vertical pressurizing die used for producing A-level fireproof insulation boards

PendingCN113043437ASelf-compactingIncrease productivityMould separation apparatusEngineeringMaterial distribution

The invention discloses a vertical pressurizing die used for producing A-level fireproof insulation boards. The vertical pressurizing die comprises a vertical die, two movable side dies and at least one spacing component, the two movable side dies are arranged on two sides of the vertical die correspondingly, and pressurizing space is formed between the vertical die and the two movable side dies. The spacing components are vertically arranged in the pressurizing space and divide the pressurizing space into multiple die cavities used for material injection, any two adjacent spacing components can move in the pressurizing space in the direction of approaching to each other, and the two movable side dies can move in the direction of approaching to each other so as to reduce the thicknesses of the multiple die cavities. Multiple A-level fireproof insulation boards can be processed and produced under the condition of one-time material distribution, and the production efficiency is greatly improved; and by adopting the form of the vertical die, vertical material injection is beneficial to self-compaction of materials in the vertical die, and the occupied production field is saved to the greatest extent.

Owner:上海圣奎机械科技有限公司

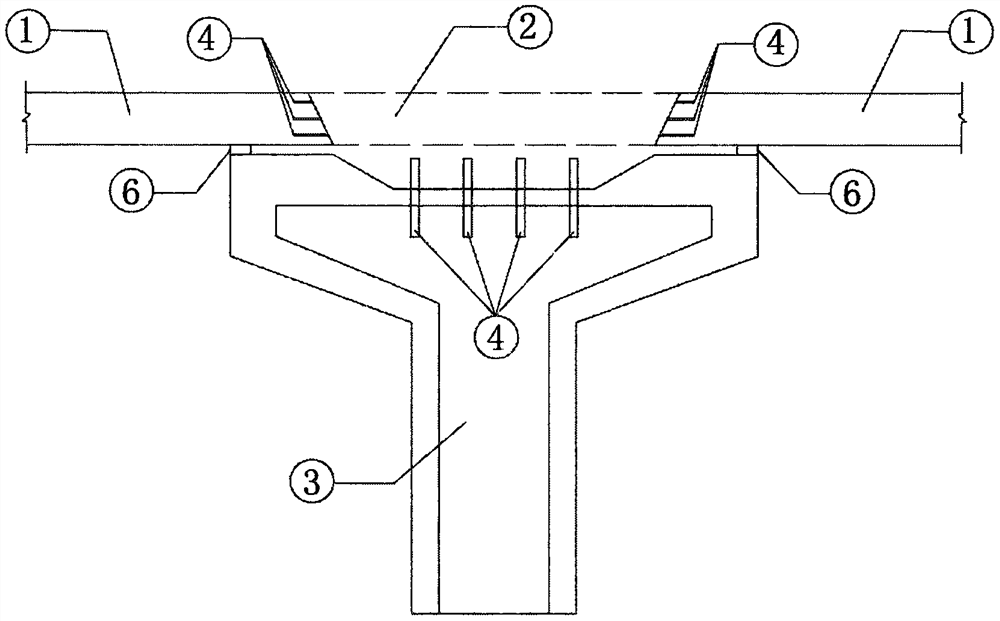

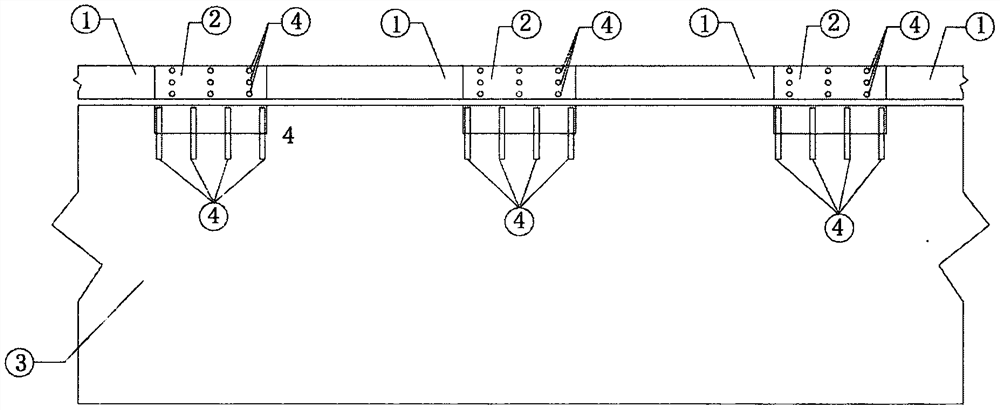

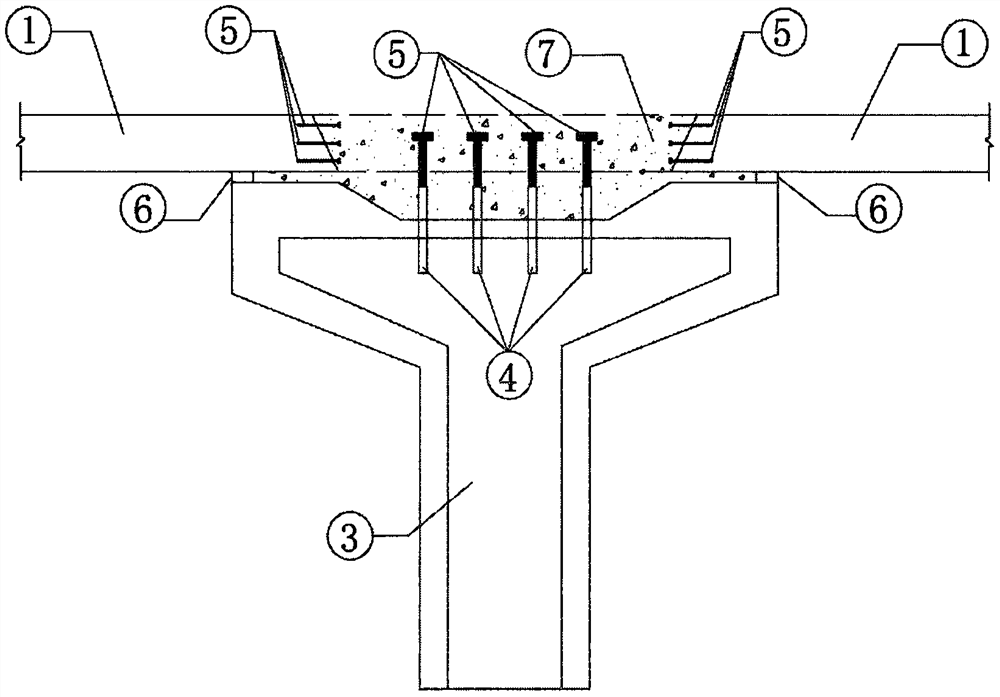

Reinforcing structure with anchoring end steel bars in connection of precast beam and bridge deck slab

InactiveCN112342894ASelf-compactingFast constructionBridge structural detailsEpoxyArchitectural engineering

The invention discloses a reinforcing structure of reinforcing steel bars with anchoring ends in connection of a precast beam and a bridge deck slab, belongs to the field of bridge structures, and mainly solves the problem that the precast bridge deck slab and the precast beam are separated from each other when being subjected to shearing force. According to the main reinforcing structure, high-strength anchoring end reinforcing steel bars coated with epoxy resin glue penetrate through reserved inserts installed at the two ends of a prefabricated bridge deck slab shear groove, then the high-strength anchoring end reinforcing steel bars are placed on the inserts of the prefabricated beam middle shear groove, and after the position is checked to be qualified, self-compacting ultrahigh-strength concrete is poured; and the high-strength steel bars with the anchoring ends, the inserts in the prefabricated bridge deck slabs and the inserts in the main beams are effectively combined into a whole. According to the prefabricated bridge deck slab and prefabricated beam connecting structure, the prefabricated bridge deck slab and the prefabricated beam are connected into a whole, the overallrigidity of combination is improved, the shear capacity is improved, and the prefabricated bridge deck slab and prefabricated beam connecting structure has the advantages of being high in constructionspeed, safe, reliable, high in economic benefit and the like.

Owner:GUANGDONG UNIV OF TECH

A manufacturing method of artificial lightweight aggregate or ultra-light aggregate multifunctional concrete

Owner:冯乃谦 +2

Heat-resistant cement-based grouting material and preparation method thereof

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

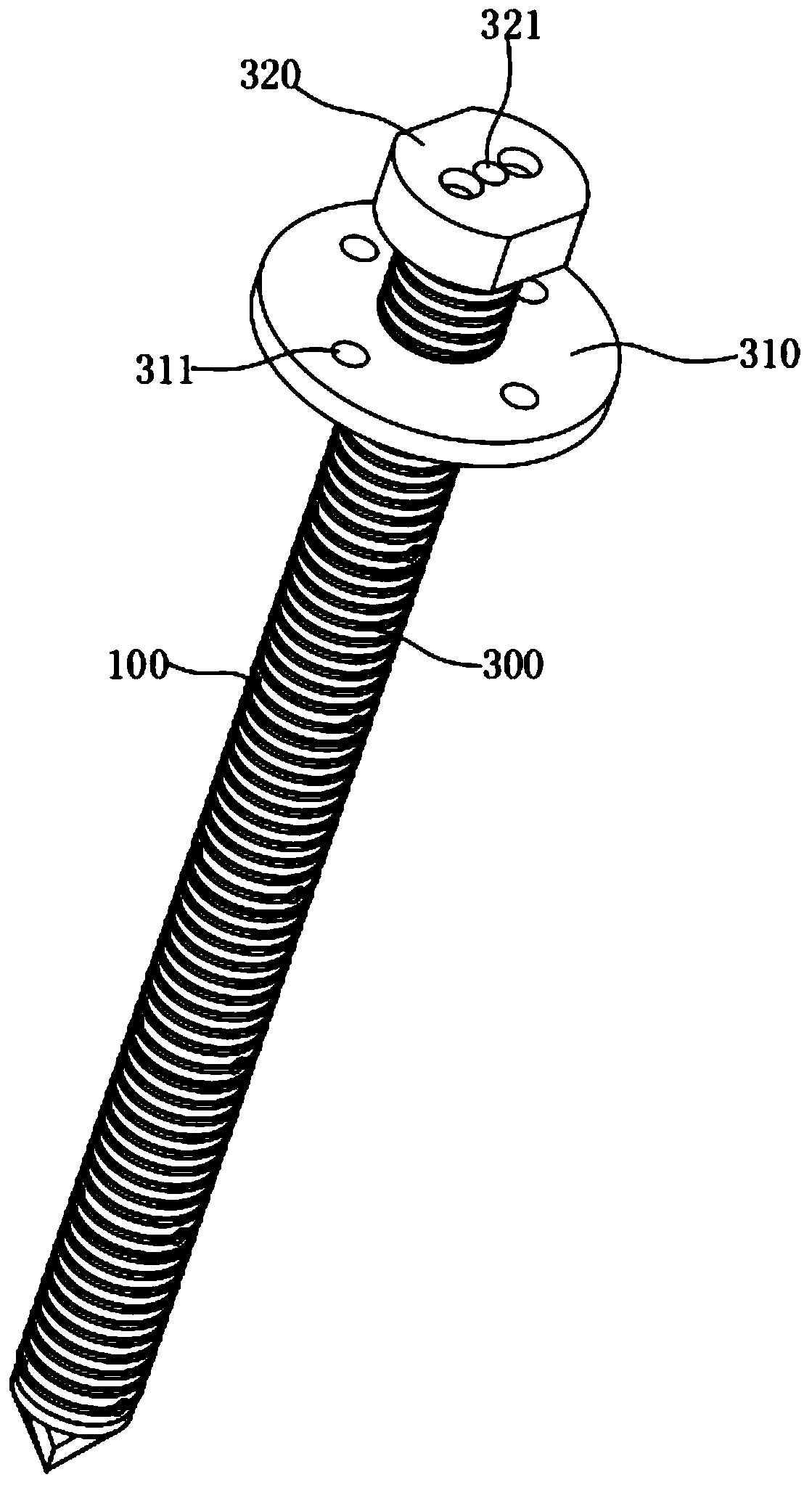

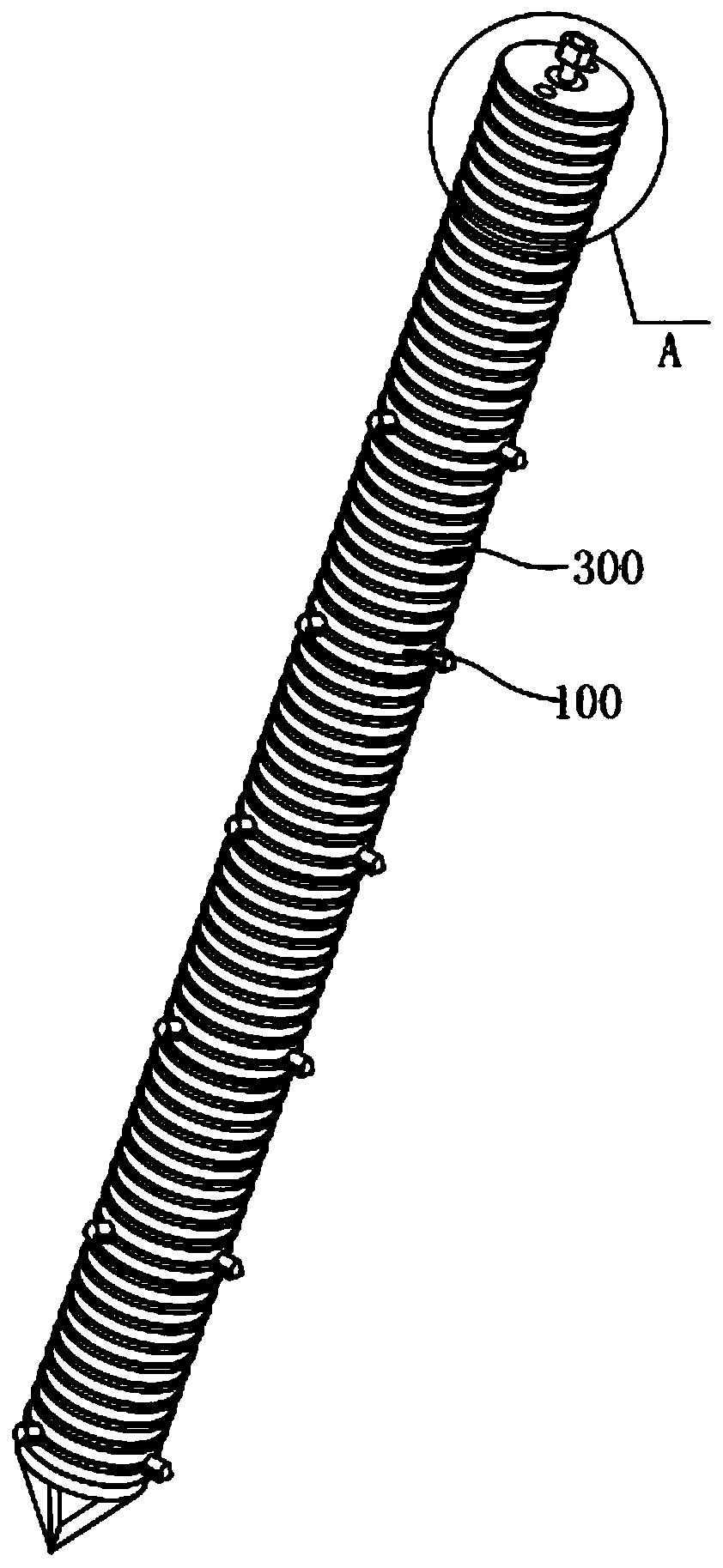

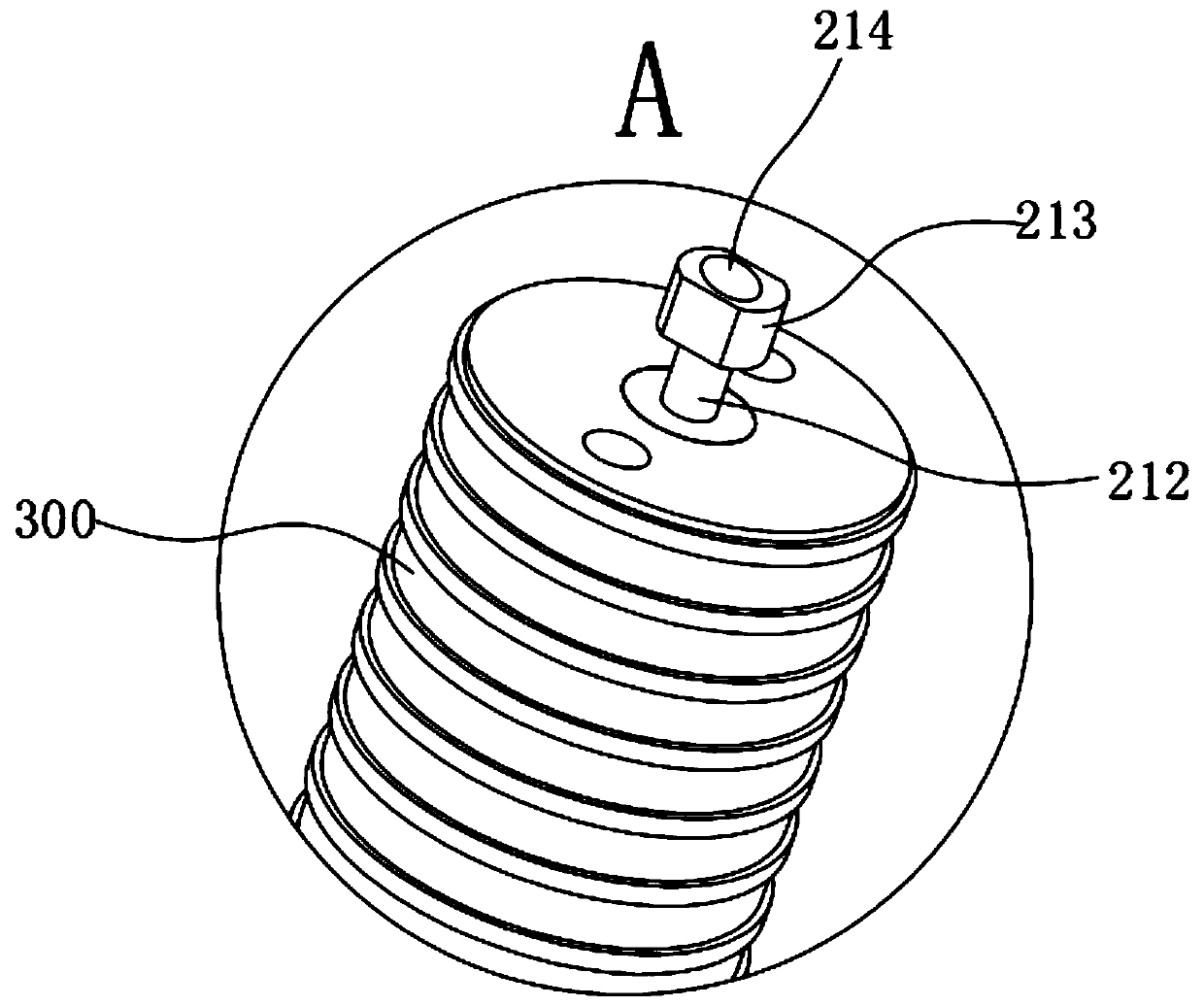

Device and method for driving pre-stressed anchor rod in tunnel with water-rich, soft and broken surrounding rock

The invention provides a device and method for driving a pre-stressed anchor rod in a tunnel with water-rich, soft and broken surrounding rocks, and belongs to the field of tunnel engineering machinery. The device for driving the pre-stressed anchor rod in the tunnel with water-rich, soft and broken surrounding rocks includes a locking mechanism and a driving mechanism; the locking mechanism includes a mounting seat, a screw rod, a nut, a locking rod and a through hole; the nut is connected on the screw rod in a threaded transmission manner; the nut is fixed at one end of the locking rod; thelocking rod slides in the through hole; the through hole is formed in the outer wall of the mounting seat; the driving mechanism includes a first bevel gear, a second bevel gear and a rotating shaft,the first bevel gear is fixed at one end of the screw rod, the second bevel gear is in transmission connection with the first bevel gear, the second bevel gear is fixed on the rotating shaft, and therotating shaft passes through the mounting seat, so that the locking of the anchor rod in the radial position is realized; and therefore, the bearing capacity of the anchor rod in the tunnel to transverse shear and bending forces can be greatly improved, the service life of the anchor rod is prolonged, and the firmness of the tunnel is strengthened.

Owner:高军

Method for preventing and controlling cracks of hollow wallboard for building

The invention relates to an installing method of a hollow wallboard for a building, in particular to a construction method for eliminating cracks of the hollow wallboard generated by self-gravity settling as priority, belonging to the technical field of buildings. The method comprises the following steps: preparing self-leveling floor mortar doped with a water-reducing agent and a cement expanding agent; wetting the floorslab part of the bottom end of the wallboard with water; drilling a grouting hole leading to a hollow cavity in the wallboard at the lower end of the wallboard; applying pressure to grout mortar to the grouting hole; leading the mortar to flow and fill part of the hollow cavity of the wallboard and bottom seams between floorslabs; and forming a mortar grouting column in the hollow cavity. The installing method can avoid the occurrence of most common cracks after the hollow wallboard is constructed on the basis that the existing construction method of the light wallboard and the basic mixing ratio of the raw materials used for the production of the wallboard are not changed basically.

Owner:YUNNAN AOSITONG FENLAN NEW BUILDING MATERIALS CO LTD

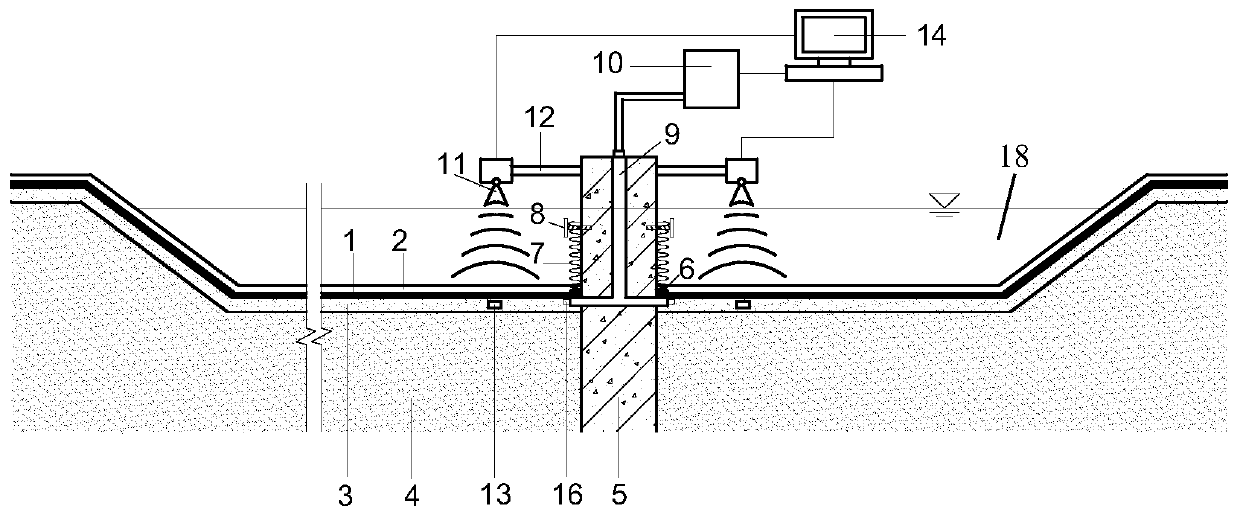

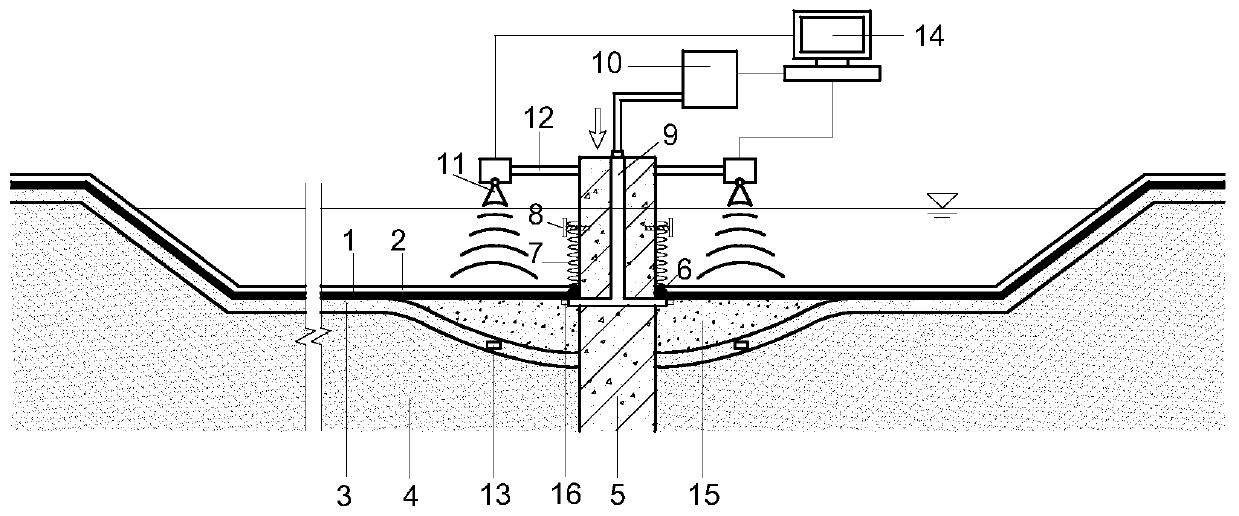

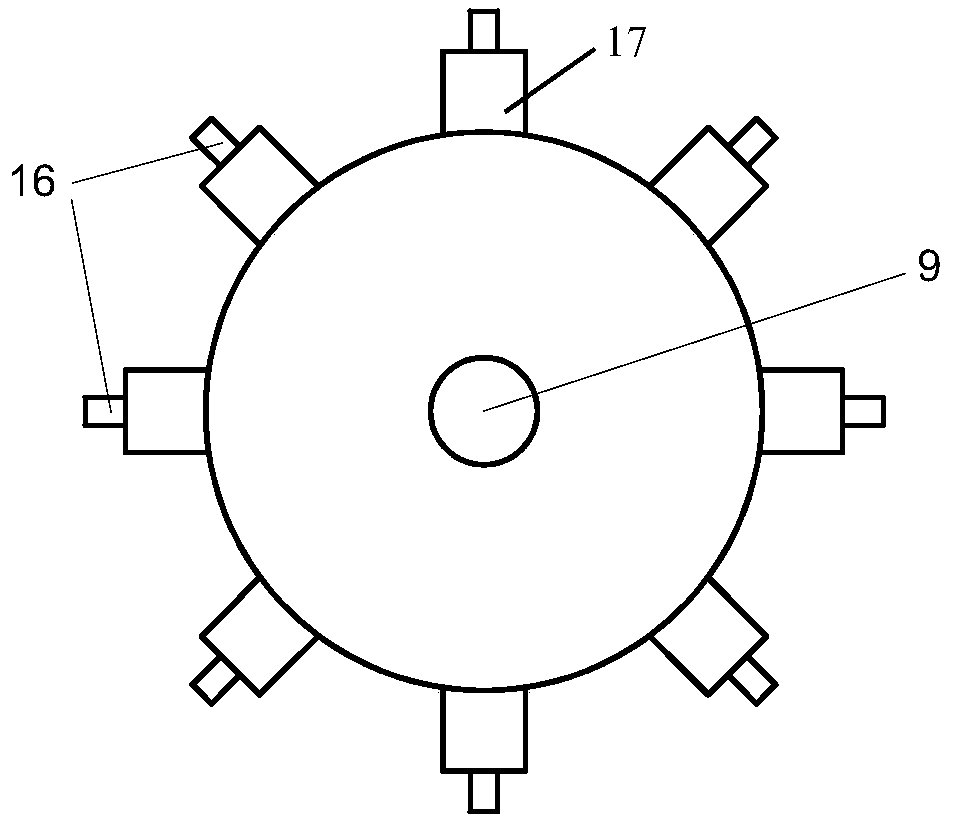

A facility and method for preventing geomembrane damage caused by subsidence around a water inlet tower

ActiveCN109518728BSolve the problem of tension damageCause damageFoundation testingProtective foundationTransceiverGeomembrane

The invention discloses a facility and method for preventing peripheral settlement of an intake tower from causing geomembrane damage. The facility comprises a grouting device and a settlement amountdetection device. The grouting device comprises a grouting machine, a grouting main pipe and multiple grouting branch pipes. The grouting main pipe is vertically arranged in the intake tower, the topof the grouting main pipe stretches out of the intake tower and is connected with the grouting machine, and the multiple grouting branch pipes are arranged at the bottom of the grouting main pipe in aradial shape. The settlement amount detection device is used for detecting the settlement amount of a reservoir around the intake tower and comprises an ultrasonic transceiver and a reflection plate.By means of the facility and method, the settlement amount detection device monitors differential settlement of a foundation around the intake tower regularly, once it is found that the settlement difference exceeds the allowable value, the grouting device carries out grouting on the settlement area in time, and differential settlement is eliminated; and if it is found that large settlement happens to the foundation again, the settlement area can be subjected to grouting repeatedly, and the problem of pulling destroying caused by too large geomembrane deformation due to foundation differential settlement around the intake tower is thoroughly solved.

Owner:HOHAI UNIV

A kind of early-strength freeze-thaw anti-spray material and preparation method thereof

The invention discloses a high-early-strength freeze-thaw resistant spraying material and a preparation method thereof. The high-early-strength freeze-thaw resistant spraying material is prepared fromthe following components in parts by weight: 100 parts of spraying dry powder, 3-5 parts of hardening accelerator and 10-15 parts of water, wherein the hardening accelerator adopts aluminium oxide asa main component; and the spraying dry powder is prepared from the following components in percentage by mass: 25%-35% of a cementing material, 35%-50% of natural grading medium sand, 15%-20% of stone, 5%-15% of redispersible latex powder, 0.1%-0.3% of polycarboxylate superplasticizer, 0.02%-0.1% of polypropylene staple fiber, and 0.01%-0.2% of polymer additive. The spraying material has high workability, stable performance, sag resistance and trowelling performance, and has rapid hardening and early strength effects after spraying construction, the preparation process is simple, the construction is convenient and efficient, and the spraying material is specially used for building construction materials of snowmobiles, sleds and racing tracks.

Owner:上海宝冶工程技术有限公司

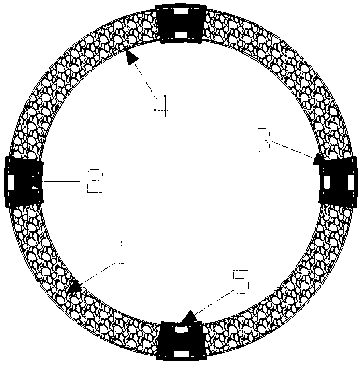

A prefabricated steel pipe concrete support and its manufacturing method

InactiveCN108361051BImprove liquiditySelf-compactingProps/chocksArchitectural engineeringAssembly (construction)

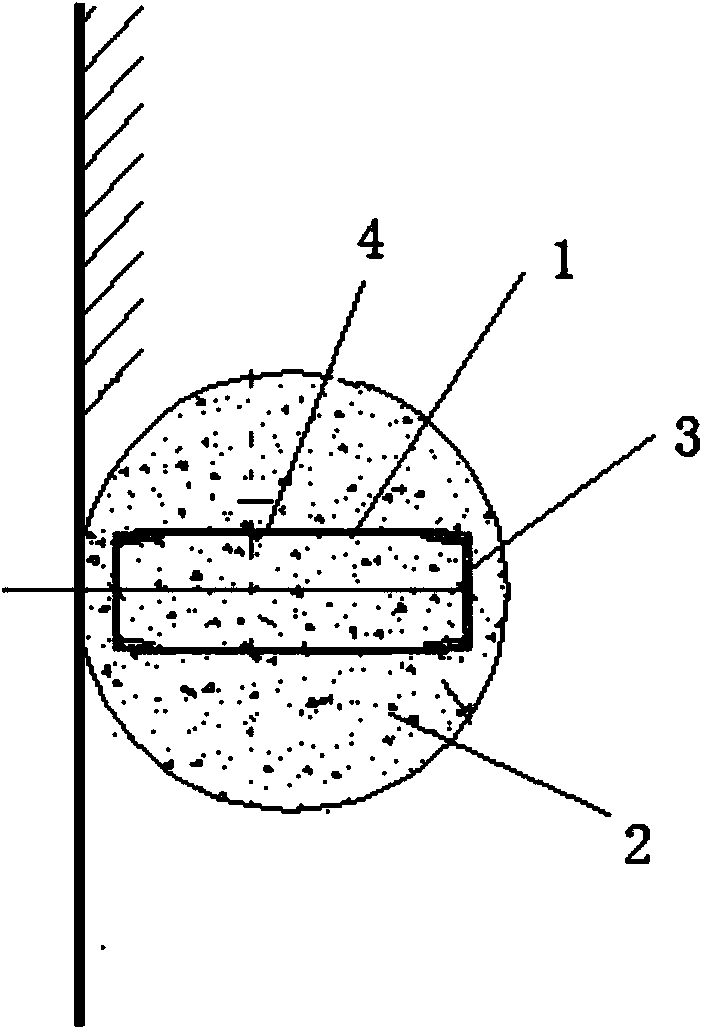

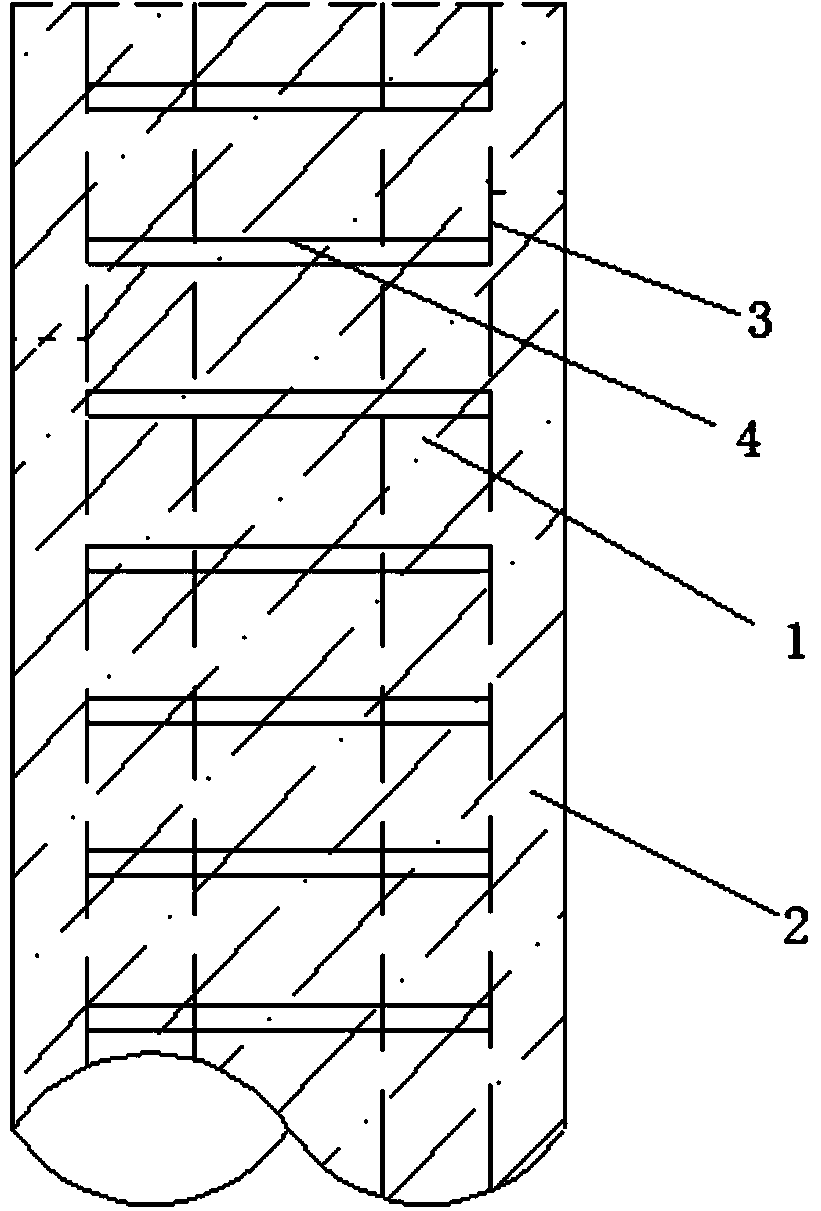

The invention discloses a prefabricated yielding concrete-filled steel tube support and a manufacturing method thereof. The prefabricated yielding concrete-filled steel tube support consists of a steel tube self-compacting concrete component and a yieldable joint. The steel tube self-compacting concrete component consists of steel tubes and self-compacting concrete packed in the middles of the steel tubes, the yieldable joint consists of a cup-shaped fixing block, a cylindrical rubber pressure bearing body and a sleeve. The multi-section steel tube self-compacting concrete component is assembled into a yieldable concrete-filled steel tube support through the yieldable joint. The prefabricated yielding concrete-filled steel tube support is manufactured by adopting an prefabricated method, has the characteristics of quick assembly and the guaranteed of construction quality, can effectively release the pressure of surrounding rock at the same time, and can be widely applied to the supportand deformation control of underground engineering tunnels.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

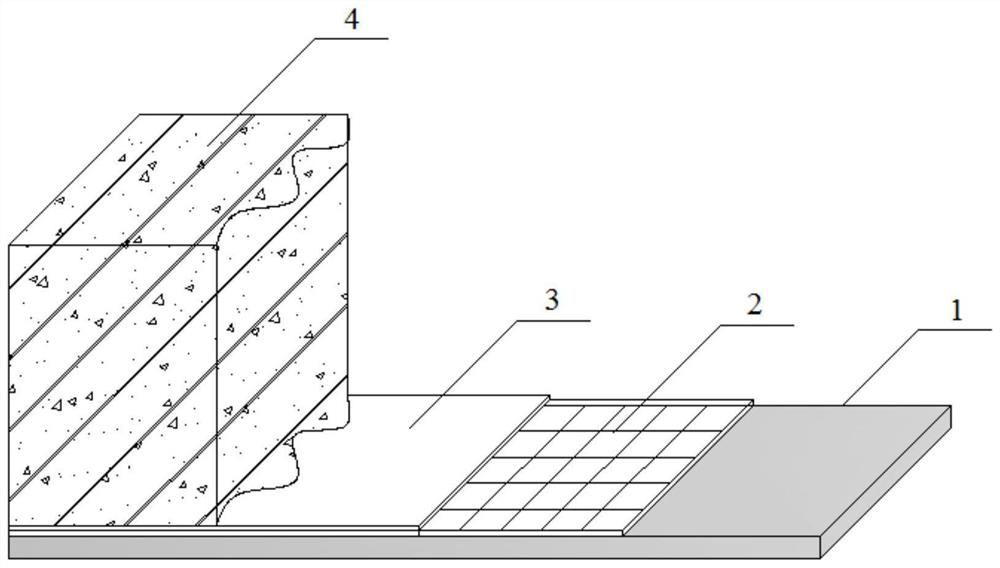

A kind of high tenacity composite beam and its construction method

ActiveCN111549648BPlay a cohesiveSpray evenlySolid waste managementBridge structural detailsRubber materialRebar

The present invention proposes a high-toughness composite beam and a construction method thereof, wherein the composite beam includes a SWCP-PVA-ECC tensile side protective layer, a grid layer arranged on the protective layer, a rubber material arranged on the grid layer, and a The reinforced concrete material layer on the rubber layer. It solves the problem that ceramic waste is not rationally utilized, and the production of cement will release a large amount of carbon dioxide into the environment, which will aggravate the greenhouse effect. The present invention replaces the existing ordinary concrete with SWCP-PVA-ECC material, which can enhance the shear resistance of beams, The flexural bearing capacity can improve the impermeability of the beam, thereby reducing the maintenance and repair times of the beam and prolonging its service life. In addition, SWCP (solid waste ceramic powder) is a recycled admixture. The recycling of SWCP can not only reduce environmental pollution, but also save costs and non-renewable resources.

Owner:HARBIN INST OF TECH

Black steel fiber reinforced concrete

Black steel fiber reinforced concrete which can be rapidly solidified, has high strength and good durability, and is not easy to crack and damage is provided by the invention. The black steel fiber reinforced concrete is prepared from the following raw materials in percentage by weight: 20%-30% of sulphoaluminate cement, 30%-40% of aggregate, 30%-40% of quartz sand, 1%-2% of steel fibers, 0.1%-0.3% of PP fibers, 0.2%-0.5% of carbon black, 0.1%-0.3% of a retarder, 0.5%-1% of an expanding agent, 0.2%-0.5% of an air entraining agent, 0.08%-0.12% of a water reducing agent and 0.5%-1% of a coagulant.

Owner:深圳立强材料科技有限公司

A mine-used inorganic ultra-fine foam filling material and its preparation method and use method

The invention provides a mineral inorganic superfine foamed filling material. The mineral inorganic superfine foamed filling material is prepared from the following raw materials in parts by weight: 8 to 18 parts of sulphoaluminate cement, 25 to 40 parts of bentonite, 3 to 10 parts of pearlite, 30 to 45 parts of fly ash, 3 to 8 parts of a foaming agent and 0.3 to 1 part of a water reducing agent. The mineral inorganic superfine foamed filling material provided by the invention is used for reinforcing coal mine crushed gangues and loose coal-rock masses and filling a goaf, a roof falling zone and a roadside, and has the characteristics of capability of pumping in a long distance, rapid condensation, uneasiness of cracking, greenness and environment friendliness. The invention further provides a preparation method and an application method of the mineral inorganic superfine foamed filling material.

Owner:ANHUI JIATAI COAL MINING TECH

Composite buffering anti-collision guardrail based on construction waste recycling

PendingCN113005956AExpand the field of resource utilization of construction wasteRaise the level of added value and utilizationSolid waste managementCeramicwareComposite structureEnvironmental resource management

The invention relates to a composite buffering anti-collision guardrail based on construction waste reutilization, the composite buffering anti-collision guardrail comprises a regenerated buffering energy-absorbing material and a steel shell, the regenerated buffering energy-absorbing material is prepared by taking construction waste as a raw material, and the steel shell is filled with the regenerated buffering energy-absorbing material to form a composite structure. The buffering performance of the anti-collision guardrail is improved, meanwhile, construction waste is recycled, the problems that resource utilization of the construction waste is difficult, and the buffering function and the blocking function of an existing anti-collision guardrail are mutually restricted are solved, and the composite buffering anti-collision guardrail has the advantages of being light in weight, good in guidance quality, low in manufacturing cost, convenient to install, construct and replace and the like. The composite buffering anti-collision guardrail is beneficial to reduction of personnel injury caused by collision accidents and guarantee of public safety, expands the field of resource utilization of the construction waste, provides a new idea for resource utilization of the construction waste, and has great social, environmental and economic benefits and wide application and popularization prospects.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

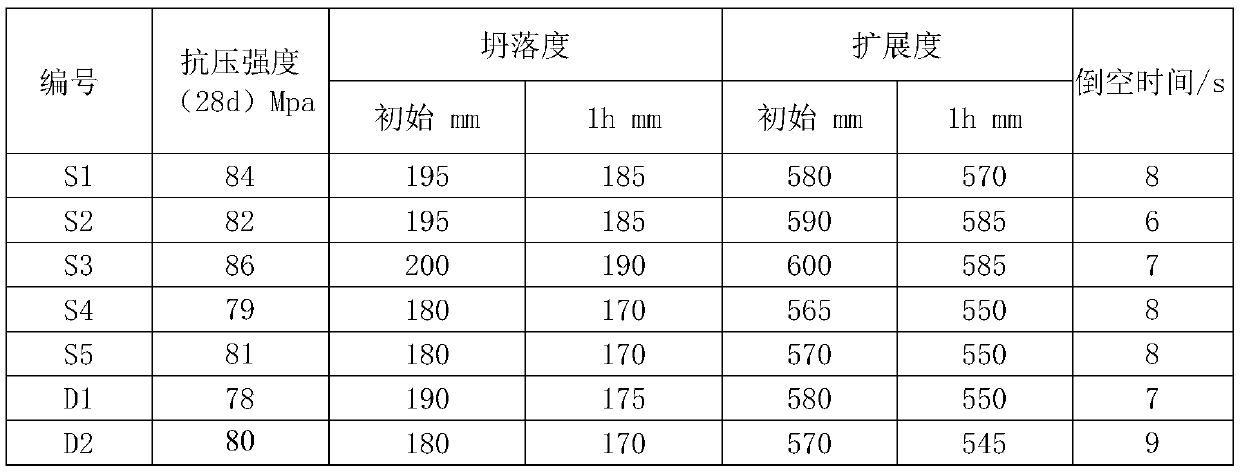

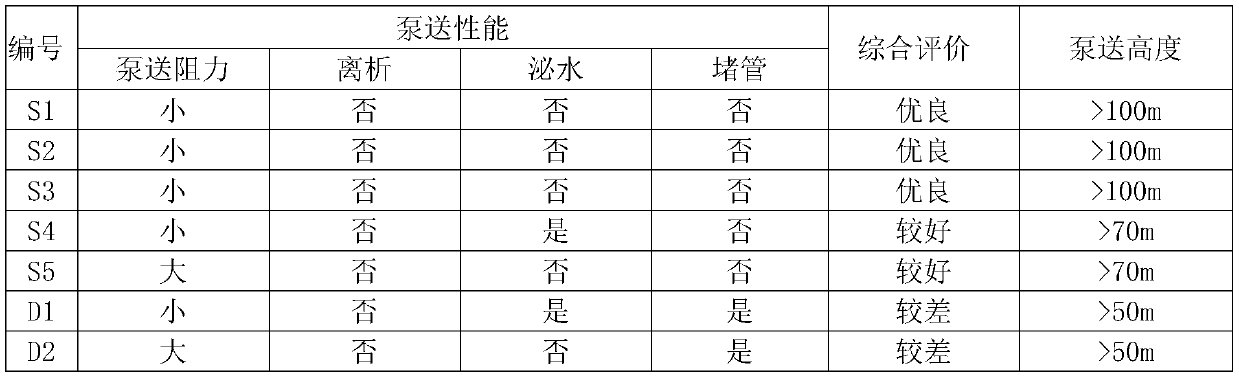

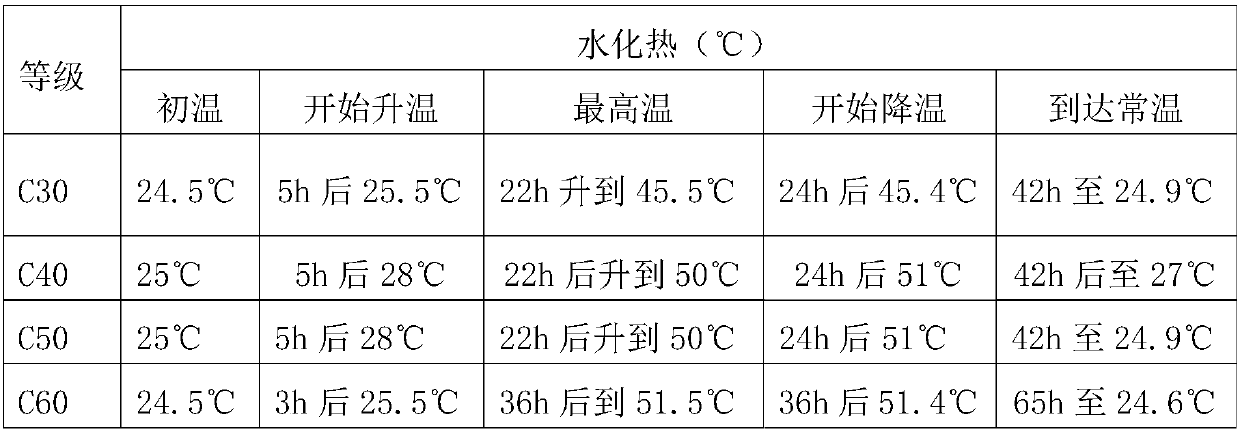

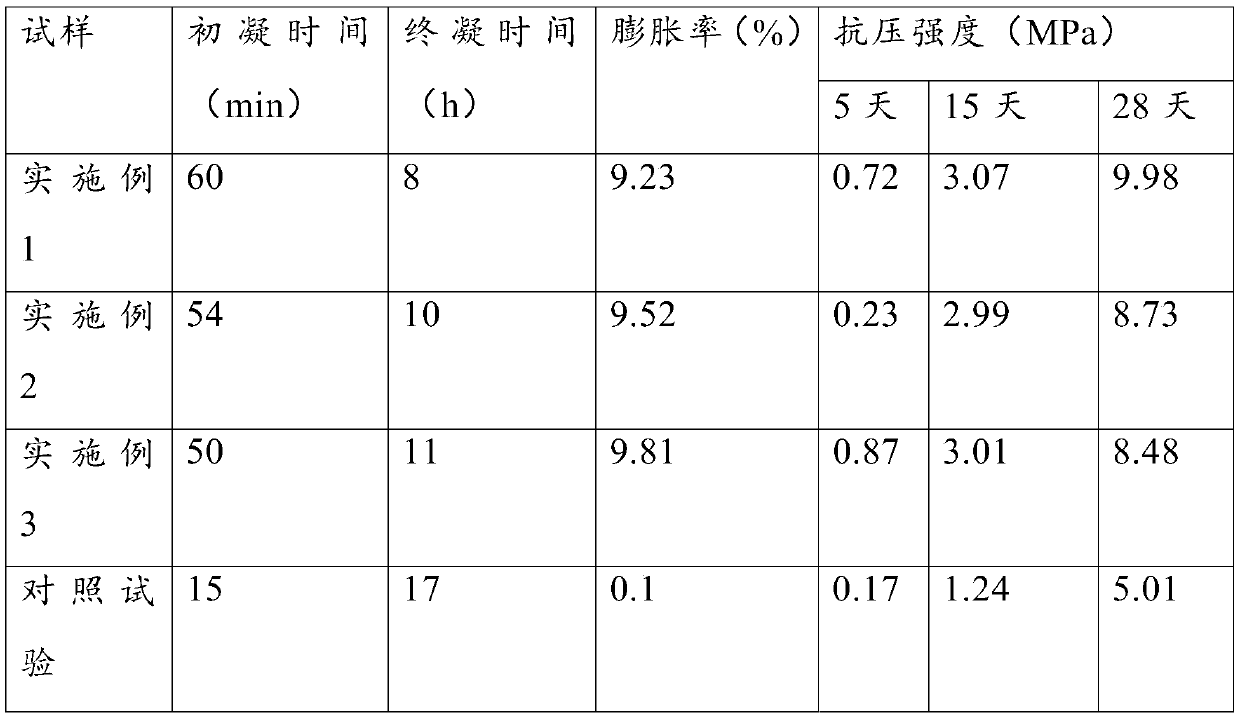

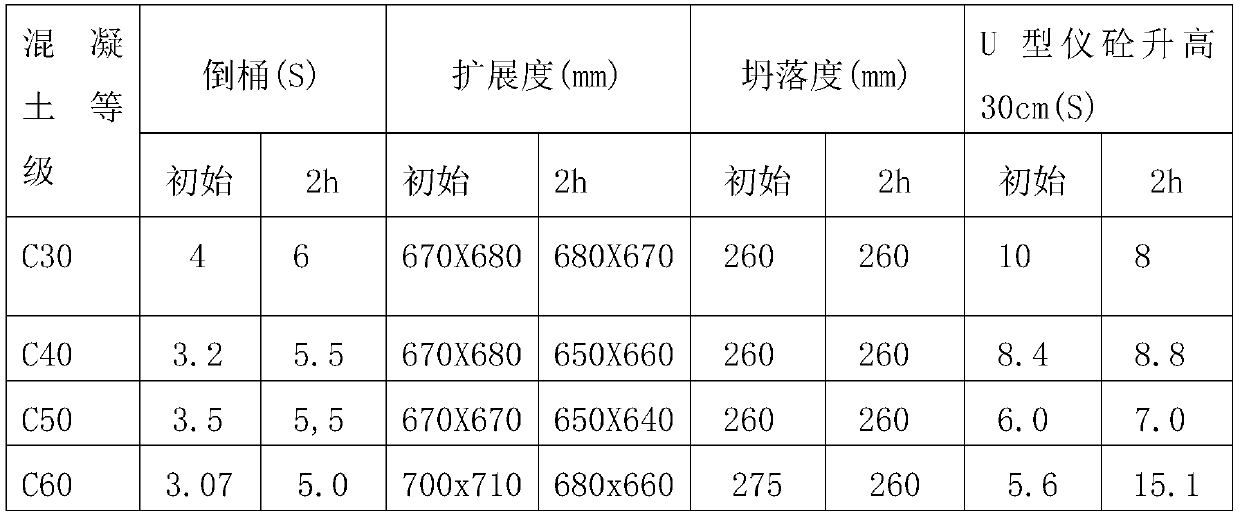

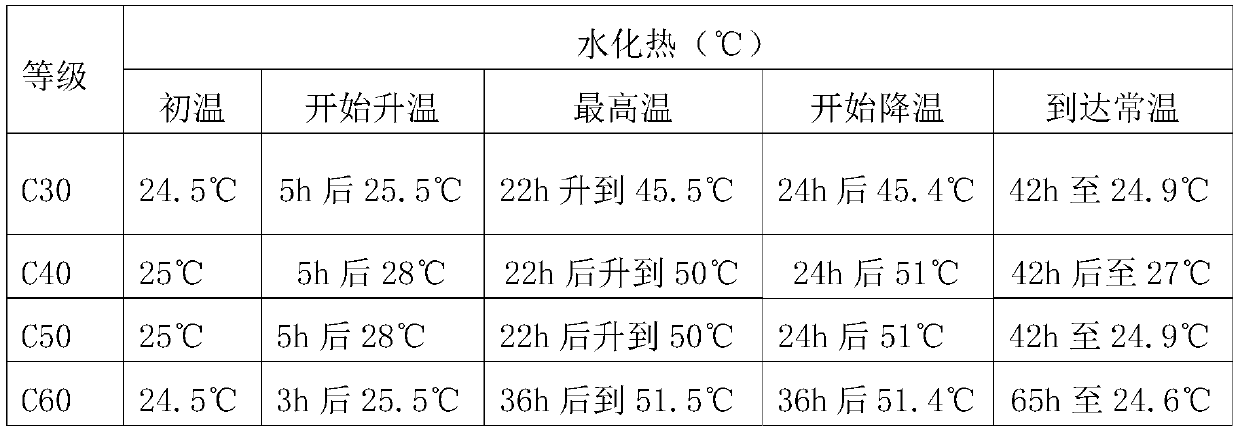

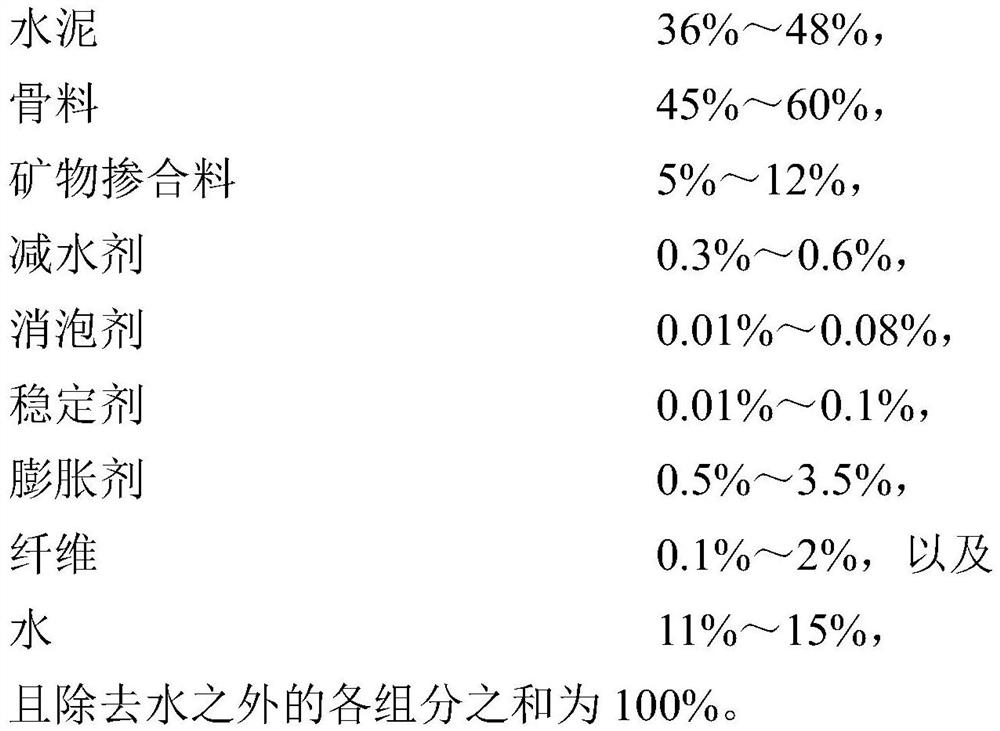

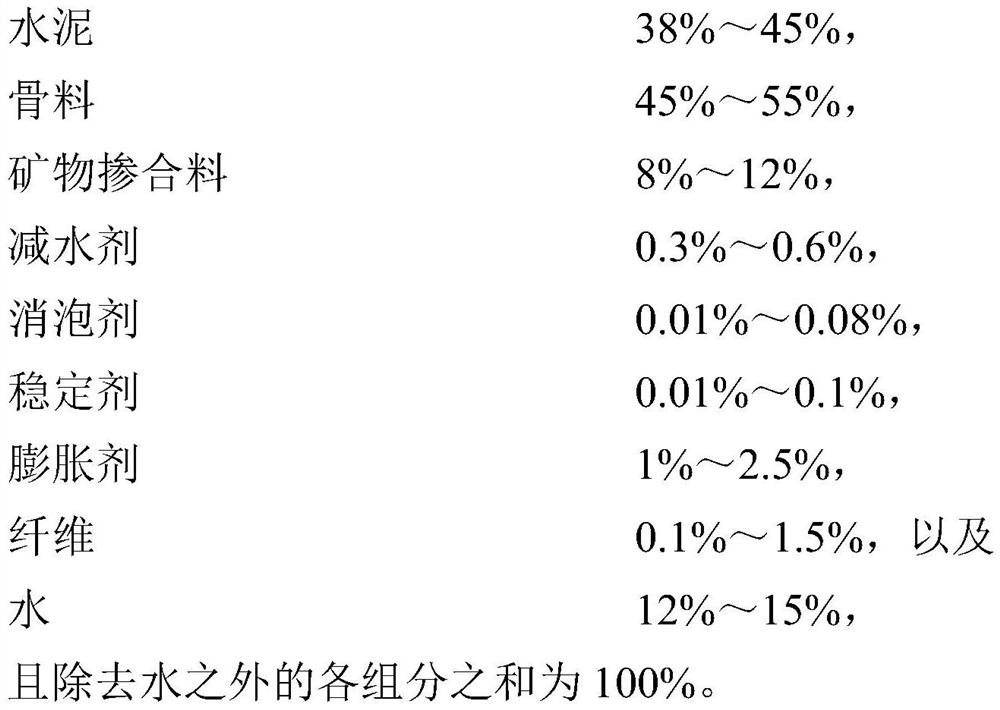

High-strength self-compacting concrete suitable for steel-concrete combined section and preparation method of high-strength self-compacting concrete

The invention discloses high-strength self-compacting concrete suitable for a steel-concrete combined section and a preparation method of the high-strength self-compacting concrete. The high-strength self-compacting concrete comprises the following components in parts by weight: 200-250 parts of water, 850-855 parts of cement, 230-260 parts of silica fume, 120-145 parts of fly ash, 1000-1100 parts of sand, 6-10 parts of a water reducing agent, 55-65 parts of an expanding agent and 100-130 parts of steel fibers. The high-strength self-compacting concrete is reasonable and scientific in formula, the high-strength self-compacting concrete is prepared through specific components and dosage, the high-strength self-compacting concrete has high strength and high bending resistance, good fluidity and self-compacting performance in the construction process can be guaranteed, and meanwhile the design requirements for durability and the like of a combined section are met.

Owner:山东高速基础设施建设有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com