Reinforcing structure with anchoring end steel bars in connection of precast beam and bridge deck slab

A technology for anchoring ends and bridge decks, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as not easy to separate, and achieve the effect of safe and reliable construction technology, simple and fast construction technology, and accelerated construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

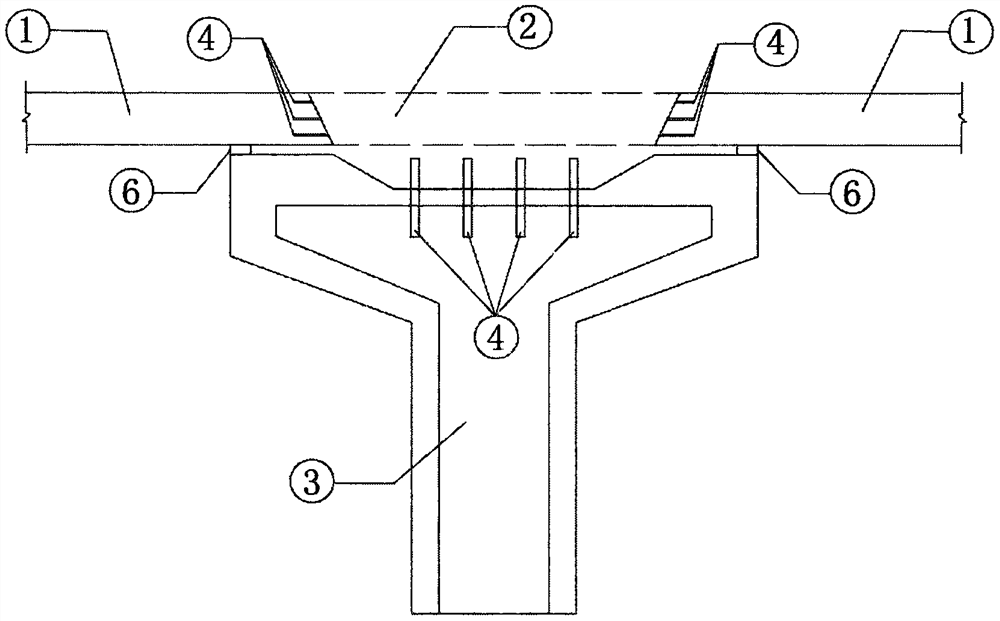

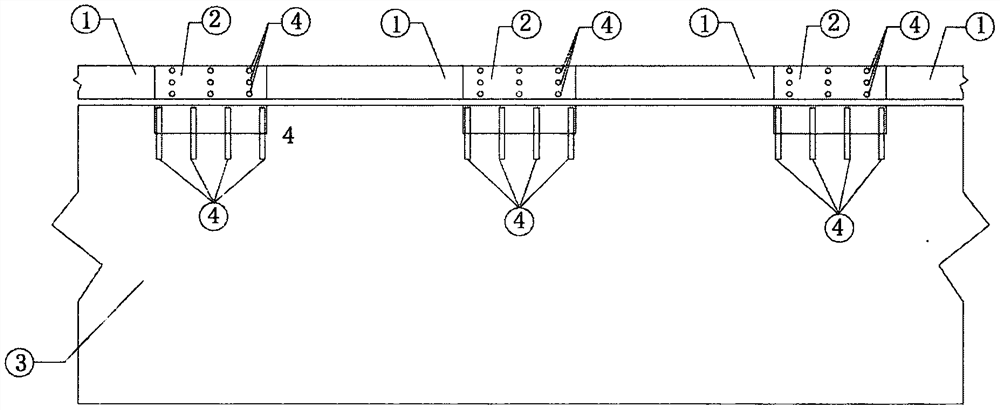

[0016] like figure 1 , figure 2 The preparation of the prefabricated bridge deck (1) 1 and the prefabricated beam (3) is completed in the prefabrication factory, and high-strength Reserve a hole for the steel insert and install the pouring insert (4).

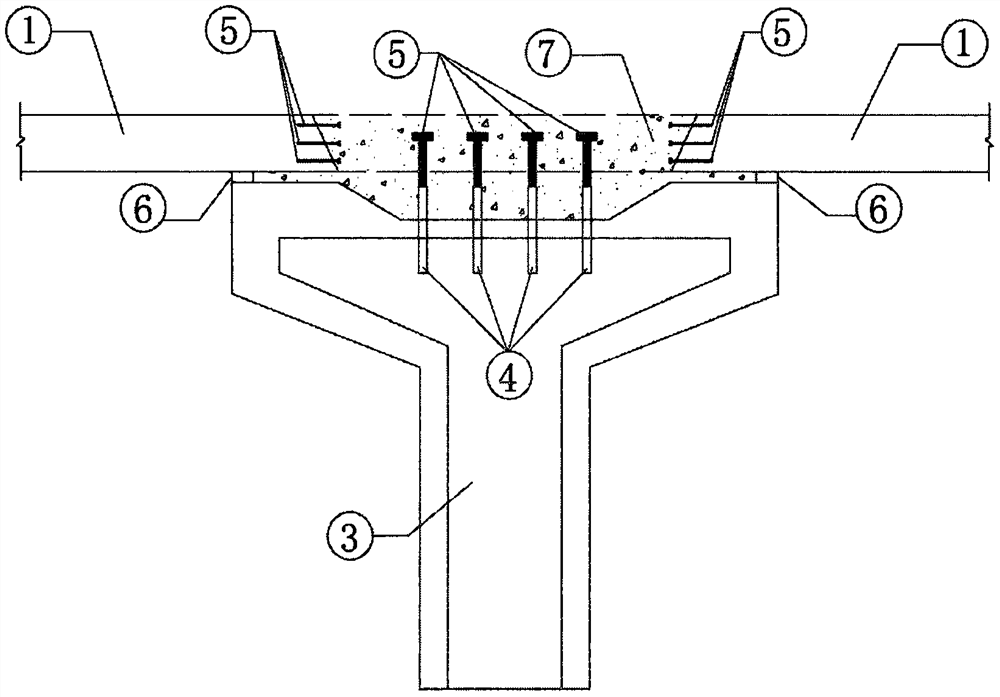

[0017] like image 3 , Figure 4 and Figure 5 As shown, when assembling the prefabricated bridge deck and the prefabricated girder, firstly, the steel bar with the anchorage end (5) passes through the inserts at both ends of the shear groove of the adjacent prefabricated bridge deck (1) and the beam top shear groove of the prefabricated beam (3) The high-strength steel inserts on the top are just staggered in position. Then pour self-compacting ultra-high-strength concrete to the shear groove to complete the connection and assembly of adjacent prefabricated bridge decks and the anchoring and assembly of bridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com