A kind of high tenacity composite beam and its construction method

A composite beam, high toughness technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of not being used effectively, intensifying the greenhouse effect, reducing permeability, etc., to expand the land use area, simple construction technology, improve The effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

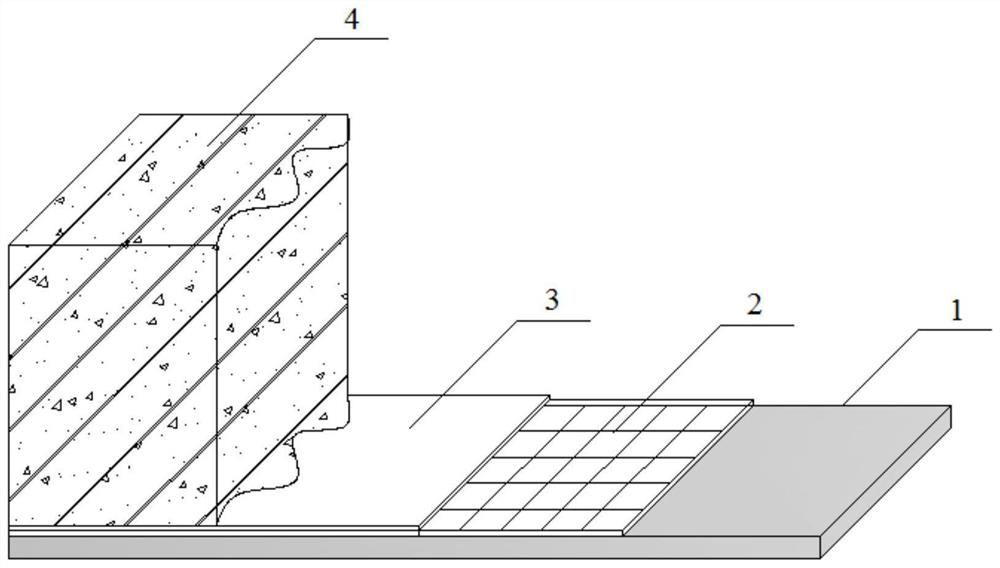

[0029] Specific implementation mode one: see figure 1 This embodiment will be described. The high-toughness composite beam described in this embodiment includes a protective layer sheet 1 in the tension area, a grid layer 2, a rubber layer 3 and a reinforced concrete layer 4, and the protective layer sheet 1 in the tension area is used as a protective layer on the tension side Located at the bottom, a grid layer 2, a rubber layer 3 and a reinforced concrete material layer 4 are sequentially arranged above the tensile zone protective layer sheet 1 from bottom to top,

[0030] The protective layer sheet 1 in the tension area is solid waste ceramic powder / polyvinyl alcohol fiber reinforced cement-based composite material (SWCP-PVA-ECC), and its proportion is cement 126.4kg / m 3 , fly ash 884.8kg / m 3 , solid waste ceramic powder 252.8kg / m 3 , quartz sand 455kg / m 3 , water 303kg / m 3 , polyvinyl alcohol fiber 26kg / m 3 , the water reducer is 1.3% of the amount of the gelling mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com