Antibacterial, mildew-proof and anti-virus melt-blown filter material and preparation method thereof

A filter material, antibacterial and anti-mildew technology, used in rayon manufacturing, physical treatment, fiber treatment, etc., can solve the problem of accelerated surface charge dissipation of electret materials, unstable filtration efficiency of filter materials, and fast decay of electret effect, etc. problem, to achieve the effect of reducing blockage, improving strength and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

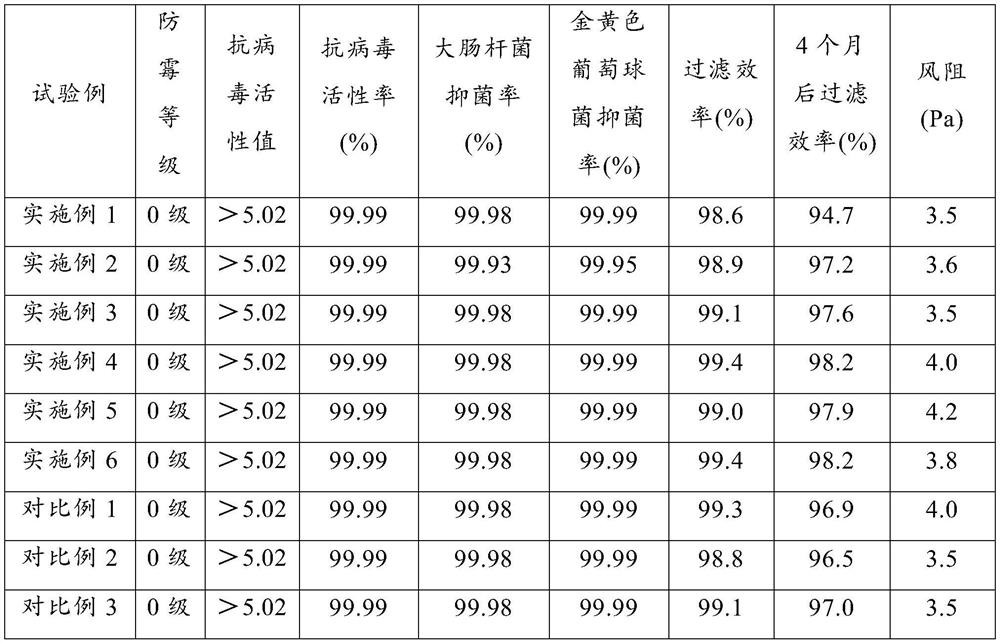

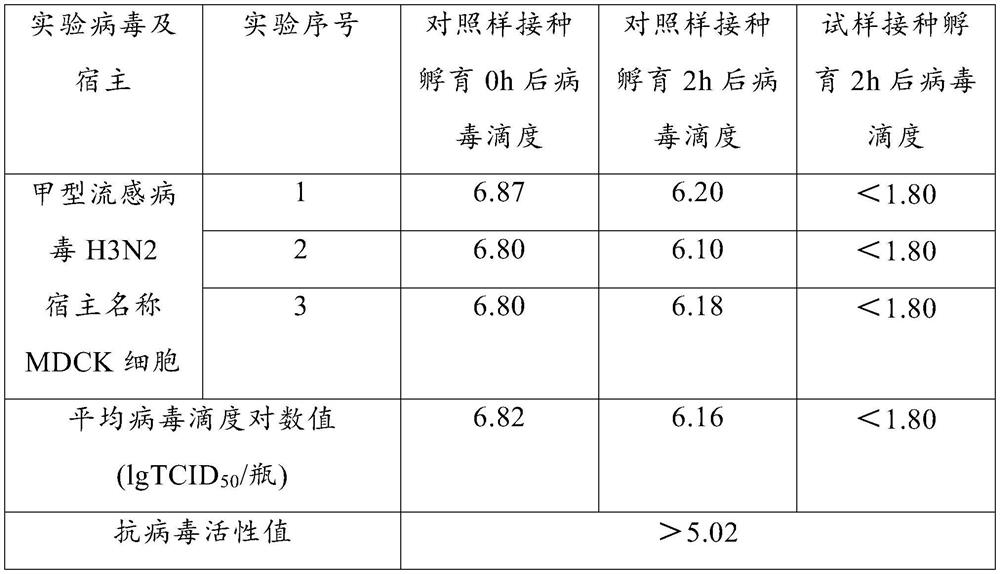

Examples

preparation example Construction

[0027] The preparation method of a kind of antibacterial, mildew-proof and anti-virus melt-blown filter material provided by the present invention comprises the following steps:

[0028] S1. Prepare a melt-blown polypropylene masterbatch containing copper, silver and zinc ion antibacterial agents; the content of the melt-blown polypropylene masterbatch is 90 to 98 parts, and the content of copper, silver and zinc ion antibacterial agents is 1 to 8 parts.

[0029] S2. Melt-blown polypropylene masterbatch described in step S1 is melt-blown and spun to obtain a melt-blown polypropylene non-woven fabric;

[0030] S3. The melt-blown polypropylene nonwoven fabric described in step S2 is subjected to water electret treatment to obtain an antibacterial, mildew-proof, and anti-virus melt-blown filter material.

[0031] Metal antibacterial agents are divided into silver ion antibacterial agents, zinc ion antibacterial agents, copper ion antibacterial agents, iron ion antibacterial agent...

Embodiment 1

[0043] A preparation method of an antibacterial, mildew-proof and anti-virus melt-blown filter material, comprising the following steps:

[0044] S1. Mix and granulate 95 parts of melt-blown polypropylene resin and 5 parts of copper-silver-zinc ion antibacterial agent to prepare a melt-blown polypropylene masterbatch containing copper-silver-zinc ion antibacterial agent; in copper-silver-zinc ion antibacterial agent, zinc ion The mass content is 0.5%, the copper ion content is 0.5%, and the silver ion content is 0.6%;

[0045] S2. Meltblown polypropylene masterbatch described in step S1 is meltblown and spun, and the temperature of the meltblown air flow is 220° C. to obtain a meltblown polypropylene nonwoven fabric;

[0046] S3. Carry out water electret treatment to the melt-blown polypropylene nonwoven fabric described in step S2 (transport the prepared high-purity water to the fan-shaped nozzle by a high-pressure pump, and carry out spunlace injection to the melt-blown poly...

Embodiment 2

[0048] A kind of preparation method of antibacterial, mildew-proof and anti-virus melt-blown filter material, compared with embodiment 1, the difference is that step S1 comprises: 95 parts of melt-blown polypropylene resin and 5 parts of copper-silver-zinc ion antibacterial agent and 1 Parts of stearic acid are mixed and granulated to prepare melt-blown polypropylene masterbatches containing copper, silver and zinc ion antibacterial agents. Others are substantially the same as in Embodiment 4, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wind resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com