Flame-retardant glue solution, preparation method and full-flame-retardant PI adhesive tape thereof

A flame retardant adhesive and flame retardant technology, which is applied in the field of flame retardant glue, flame retardant PI tape, and preparation, can solve the problems of pressure-sensitive adhesive and initial adhesion decrease, less flame retardancy, and sticking problems, etc. , to achieve the effect of reducing the probability of flammability and explosion, improving safety and excellent fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

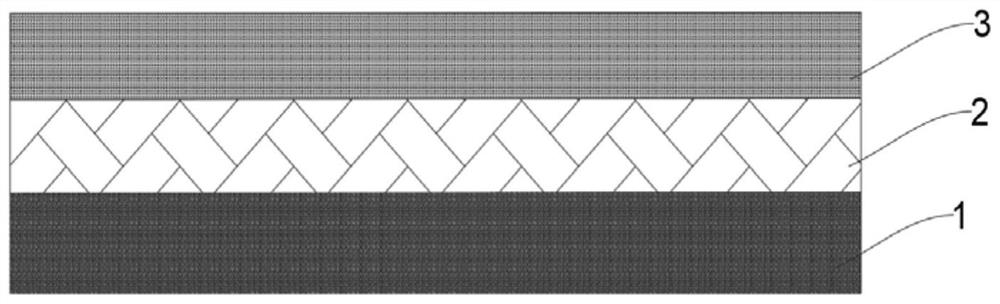

Image

Examples

Embodiment 1

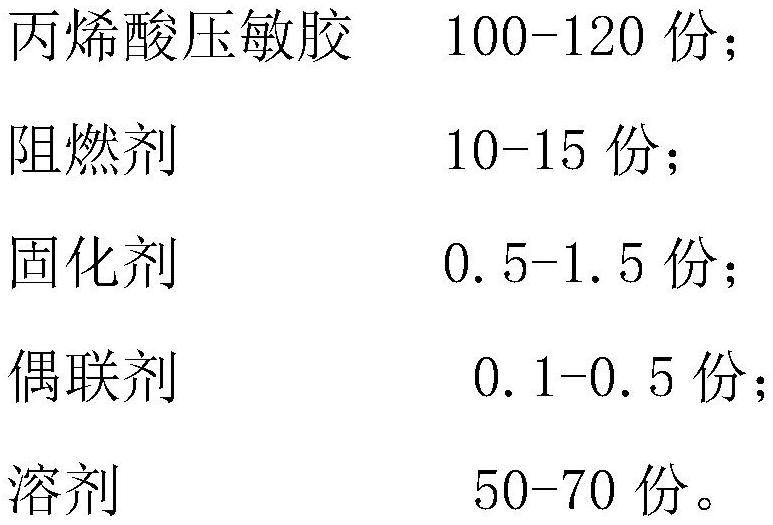

[0036] A kind of flame-retardant glue liquid, comprises the raw material of following weight part:

[0037]

[0038] Among them: acrylic pressure-sensitive adhesive is methyl acrylate pressure-sensitive adhesive; flame retardant is liquid triphenyl phosphate flame retardant; curing agent is metal salt curing agent (aluminum acetylacetonate); coupling agent is silane coupling agent (vinyl triethoxysilane); solvent is ethyl acetate;

[0039] A preparation method of flame retardant glue, comprising the following steps:

[0040] S1, prepare materials according to the parts by weight of raw materials;

[0041] S2. Mix the acrylic pressure-sensitive adhesive with half the amount of solvent, fully stir for 10 minutes, and treat for 30 minutes under the ultrasonic power of 200W;

[0042] S3. Mix the flame retardant with the other half of the solvent, stir thoroughly for 10 minutes, and treat it for 30 minutes under the ultrasonic power of 100W, add it to the acrylic pressure-sens...

Embodiment 2

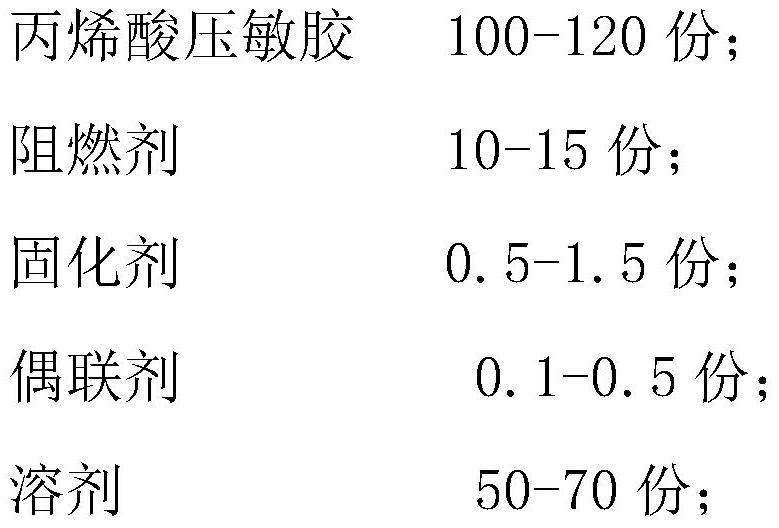

[0046] A kind of flame-retardant glue liquid, comprises the raw material of following weight part:

[0047]

[0048]

[0049] Among them: acrylic pressure-sensitive adhesive is ethyl acrylate pressure-sensitive adhesive; flame retardant is liquid triphenyl phosphate flame retardant; curing agent is epoxy curing agent (diaminodiphenylmethane); coupling agent is titanium Ester coupling agent (isopropyl triisostearyl titanate); solvent is toluene;

[0050] A preparation method of flame retardant glue, comprising the following steps:

[0051] S1, prepare materials according to the parts by weight of raw materials;

[0052] S2. Mix the acrylic pressure-sensitive adhesive with half the amount of solvent, stir thoroughly for 30 minutes, and process for 60 minutes at an ultrasonic power of 300W;

[0053] S3. Mix the flame retardant with the other half of the solvent, stir thoroughly for 30 minutes, and treat it for 60 minutes under the ultrasonic power of 200W, add it to the a...

Embodiment 3

[0057] A kind of flame-retardant glue liquid, comprises the raw material of following weight part:

[0058]

[0059]

[0060] Among them: acrylic pressure-sensitive adhesive is n-propyl acrylate pressure-sensitive adhesive; flame retardant is liquid triphenyl phosphate flame retardant; curing agent is isocyanate curing agent (dicyclohexylmethane diisocyanate), aziridine curing agent agent (XH-5008H); coupling agent is aluminate coupling agent (distearoyloxyisopropyl aluminate); solvent is butyl acetate; tackifying resin is coumarone-indene resin; auxiliary agent It is ultrafine silicon dioxide with a particle size of 3-8 μm; a method for preparing a flame-retardant glue, comprising the following steps:

[0061] S1, prepare materials according to the parts by weight of raw materials;

[0062] S2. Mix the acrylic pressure-sensitive adhesive, additives and half the amount of solvent, stir thoroughly for 10 minutes, and treat for 30 minutes under the ultrasonic power of 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com