Preparation method of silicon-carbon negative electrode material of layered structure

A negative electrode material and layered structure technology, which is applied in the field of preparation of silicon-carbon negative electrode materials with a layered structure, can solve problems that hinder the application of silicon negative electrode materials for lithium-ion batteries, electrode materials lose electrical contact, and material interface instability, etc., to achieve Increased electrical conductivity, reduced overall expansion rate, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

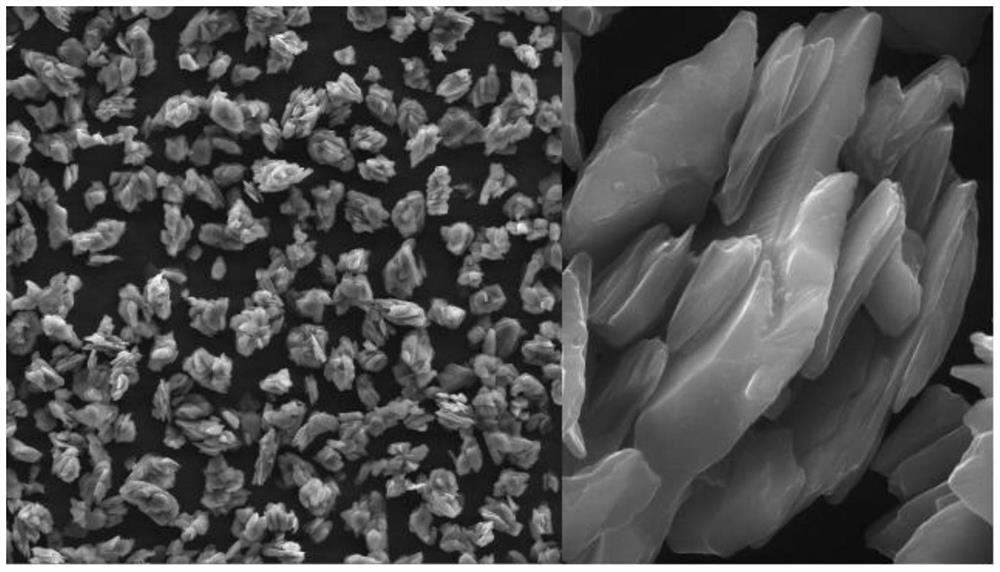

[0036] This specific embodiment is to prepare a silicon-carbon negative electrode material with a layered structure, and the specific steps of its preparation process are:

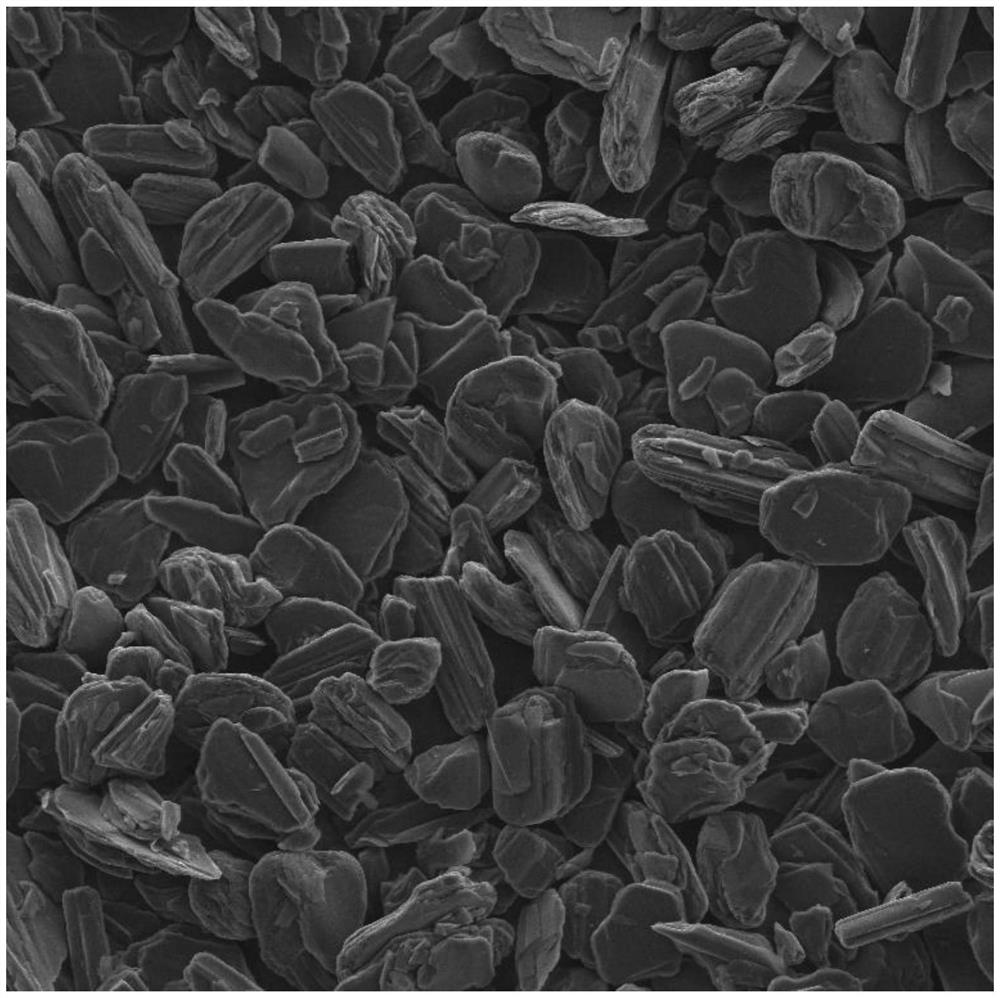

[0037] Step 1, select graphite and silicon particles of flake single particles, the graphite particles of the flake single particles have a length of 5-8 μm, a width of 3-5 μm, and a thickness of 1-3 μm, and the silicon particles of the flake single particles The length is 3-5 μm, the width is 2-4 μm, the thickness is 0.5-2 μm, and the mass ratio of graphite particles to silicon particles is 20:1, so that they are mixed in a high-speed disperser for 2 hours to obtain graphite / silicon mixed powder;

[0038] Step 2. Add graphite / silicon mixed powder into a deionized aqueous solution with a mass percentage of carbon source precursor of 1%, and the carbon source precursor is a composition of polyethylene glycol ether and diethyl phthalate , by physically stirring and ultrasonically dispersing 5H to obtain a mi...

Embodiment 2

[0044] This specific embodiment is to prepare a silicon-carbon negative electrode material with a layered structure, and the specific steps of its preparation process are:

[0045] Step 1, select graphite and silicon particles of flake single particles, the graphite particles of the flake single particles have a length of 8-12 μm, a width of 5-8 μm, and a thickness of 1-3 μm, and the silicon particles of the flake single particles The length is 5-8 μm, the width is 3-5 μm, the thickness is 0.5-2 μm, and the mass ratio of graphite particles to silicon particles is 10:1, so that they are mixed in a high-speed disperser for 6 hours to obtain graphite / silicon mixed powder;

[0046] Step 2. Add the graphite / silicon mixed powder into a deionized aqueous solution with a carbon source precursor of 10% by mass. The carbon source precursor is pitch, and disperse the mixed powder by physical stirring and ultrasonic dispersion for 13H to obtain a mixed powder suspension liquid;

[0047] ...

Embodiment 3

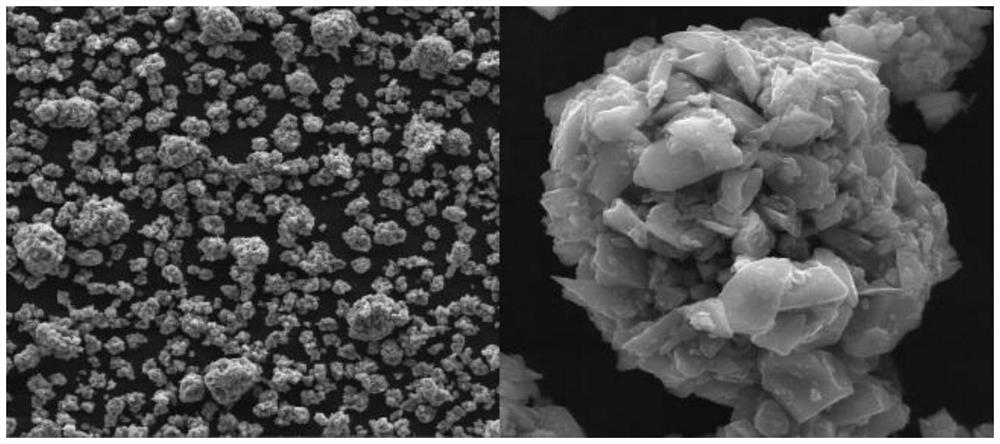

[0052] This specific embodiment is to prepare a silicon-carbon negative electrode material with a layered structure, and the specific steps of its preparation process are:

[0053] Step 1, select graphite and silicon particles of flake-like single particles, the graphite particles of the flake-like single particles have a length of 12-15 μm, a width of 8-10 μm, and a thickness of 1-3 μm, and the silicon particles of the flake-like single particles The length is 8-10 μm, the width is 5-7 μm, and the thickness is 0.5-2 μm. The mass ratio of graphite particles to silicon particles is 5:2, and they are mixed in a high-speed disperser for 10 hours to obtain graphite / silicon mixed powder;

[0054] Step 2. Add the graphite / silicon mixed powder into a deionized aqueous solution with a carbon source precursor of 20% by mass. The carbon source precursor is a composition of methanol, acetone and ethyl acetate. Physical stirring and ultrasound Disperse for 20 hours to obtain a mixed powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com