A kind of preparation method with layered structure silicon carbon negative electrode material

A technology of negative electrode material and layered structure, applied in the field of preparation of silicon carbon negative electrode material with layered structure, can solve the problems of hindering the application of silicon negative electrode material of lithium ion battery, loss of electrical contact of electrode material, unstable material interface, etc. Effects of increased conductivity, reduced overall expansion rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This specific embodiment is to prepare a silicon-carbon negative electrode material with a layered structure, and the specific steps of its preparation process are:

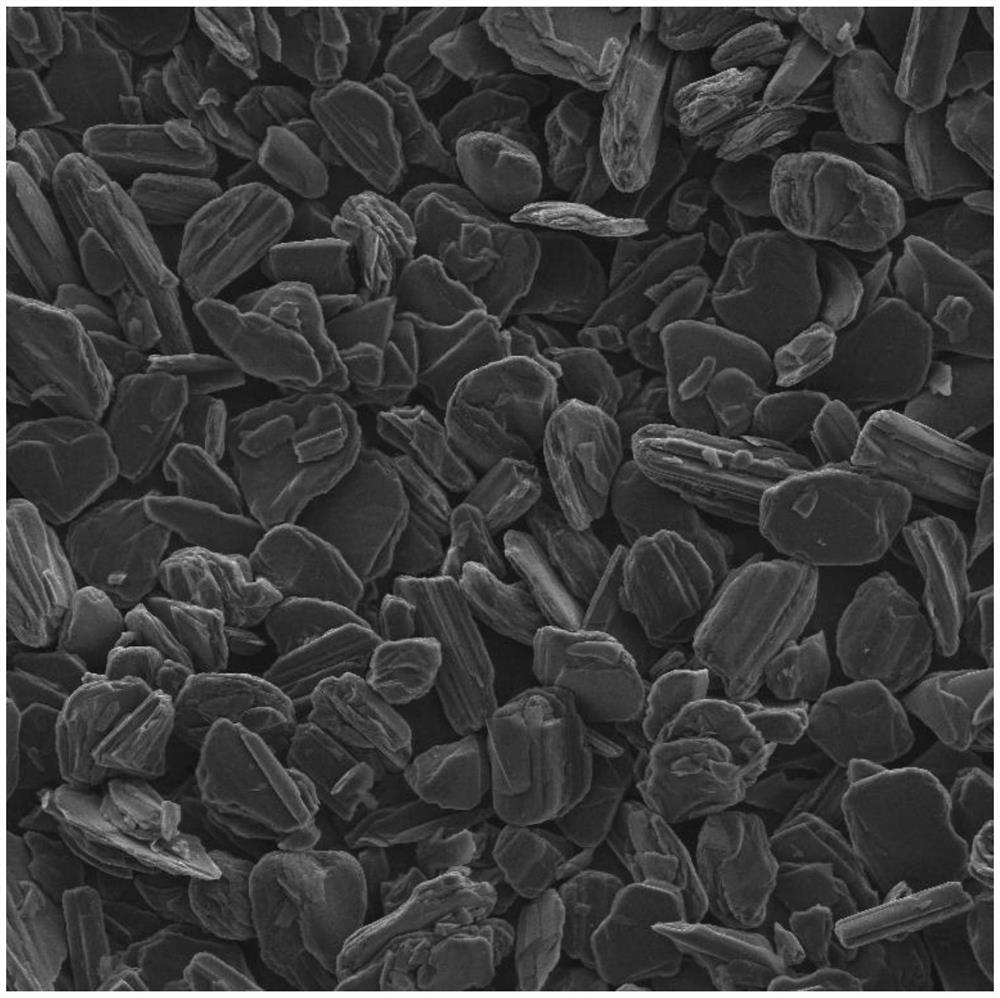

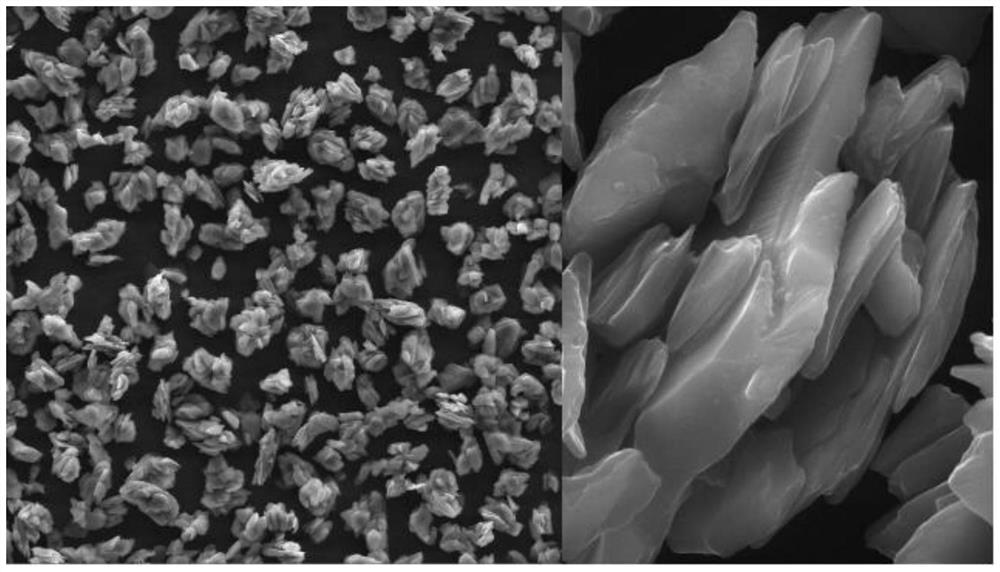

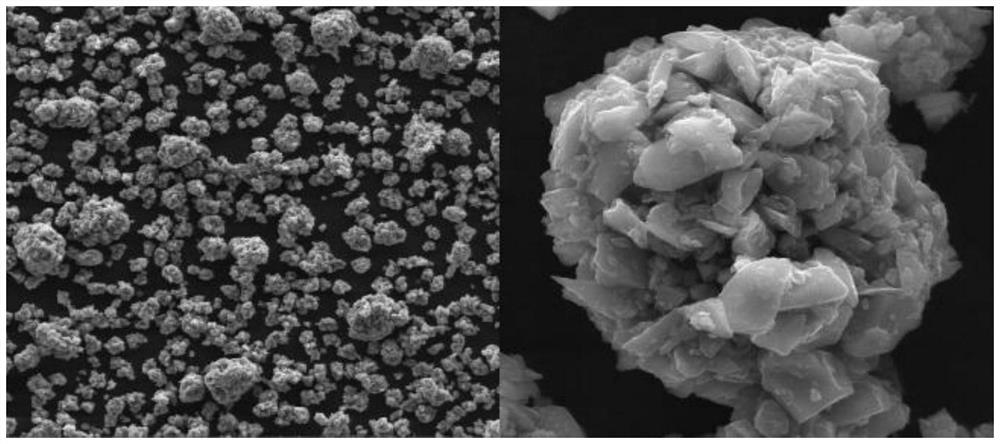

[0037] Step 1, select graphite and silicon particles of flake single particles, the graphite particles of the flake single particles have a length of 5-8 μm, a width of 3-5 μm, and a thickness of 1-3 μm, and the silicon particles of the flake single particles The length is 3-5 μm, the width is 2-4 μm, the thickness is 0.5-2 μm, and the mass ratio of graphite particles to silicon particles is 20:1, so that they are mixed in a high-speed disperser for 2 hours to obtain graphite / silicon mixed powder;

[0038] Step 2. Add graphite / silicon mixed powder into a deionized aqueous solution with a mass percentage of carbon source precursor of 1%, and the carbon source precursor is a composition of polyethylene glycol ether and diethyl phthalate , by physically stirring and ultrasonically dispersing 5H to obtain a mi...

Embodiment 2

[0044] This specific embodiment is to prepare a silicon-carbon negative electrode material with a layered structure, and the specific steps of its preparation process are:

[0045] Step 1, select graphite and silicon particles of flake single particles, the graphite particles of the flake single particles have a length of 8-12 μm, a width of 5-8 μm, and a thickness of 1-3 μm, and the silicon particles of the flake single particles The length is 5-8 μm, the width is 3-5 μm, the thickness is 0.5-2 μm, and the mass ratio of graphite particles to silicon particles is 10:1, so that they are mixed in a high-speed disperser for 6 hours to obtain graphite / silicon mixed powder;

[0046] Step 2. Add the graphite / silicon mixed powder into a deionized aqueous solution with a carbon source precursor of 10% by mass. The carbon source precursor is pitch, and disperse the mixed powder by physical stirring and ultrasonic dispersion for 13H to obtain a mixed powder suspension liquid;

[0047] ...

Embodiment 3

[0052] This specific embodiment is to prepare a silicon-carbon negative electrode material with a layered structure, and the specific steps of its preparation process are:

[0053] Step 1, select graphite and silicon particles of flake-like single particles, the graphite particles of the flake-like single particles have a length of 12-15 μm, a width of 8-10 μm, and a thickness of 1-3 μm, and the silicon particles of the flake-like single particles The length is 8-10 μm, the width is 5-7 μm, and the thickness is 0.5-2 μm. The mass ratio of graphite particles to silicon particles is 5:2, and they are mixed in a high-speed disperser for 10 hours to obtain graphite / silicon mixed powder;

[0054] Step 2. Add the graphite / silicon mixed powder into a deionized aqueous solution with a carbon source precursor of 20% by mass. The carbon source precursor is a composition of methanol, acetone and ethyl acetate. Physical stirring and ultrasound Disperse for 20 hours to obtain a mixed powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com