Composite buffering anti-collision guardrail based on construction waste recycling

A construction waste and anti-collision guardrail technology, which is applied in construction, application, home appliances, etc., can solve the problem of mutual restriction between the buffering and blocking functions of the construction waste resource utilization, and achieve the improvement of added value and utilization level, construction Convenience and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

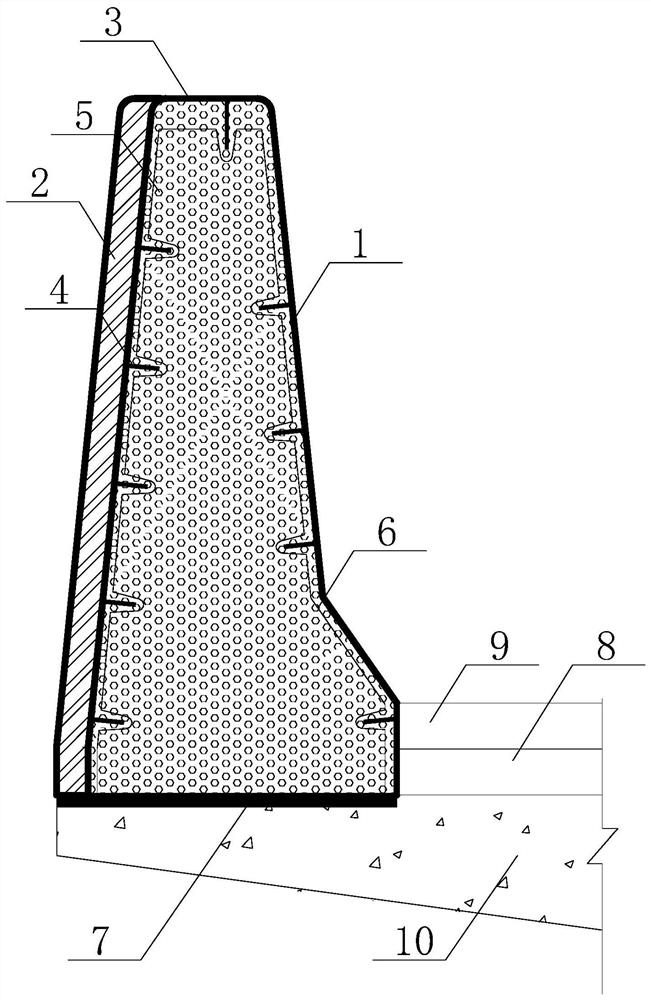

[0055] Such as figure 1 As shown, the present embodiment is based on the composite buffer anti-collision guardrail of the construction waste, including the catering surface steel plate 1, non-welcoming surface steel plate 2, top plate 3, longitudinal rib 4, regenerated buffer absorbent material 5 and vertical The ribs 6, the longitudinal rib 4 welded to the weltering surface steel plate 1, the non-welcoming face steel 2, the top plate 3, and constitutes a steel housing with the vertical rib 6, the internal perfusion regeneration buffer suction material 5. A plurality of vertical ribs 4 and vertical ribs 6 are provided. Welcome surface steel plate 1, non-welcoming surface steel plate 2, top plate 3 and longitudinal ribs 4, etc. can be used to facilitate transportation of small segments.

[0056] The guardrail is mounted on the concrete beam 10 with a weltering surface steel plate 1 with longitudinal ribs 4 with a longitudinal rib 4, and the vertical ribs 6 and the concrete beam 10 ...

Embodiment 2

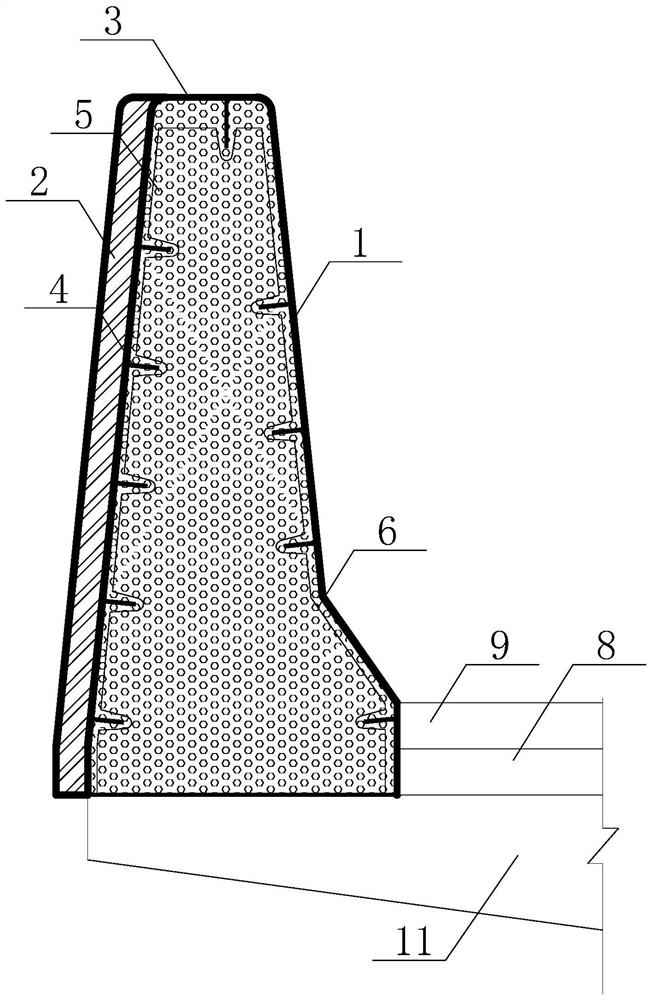

[0058] Such as figure 2 As shown, the present embodiment is based on the composite buffer anti-collision guardrail of the construction waste, including the catering surface steel plate 1, non-welcoming surface steel plate 2, top plate 3, longitudinal rib 4, regenerated buffer absorbent material 5 and vertical The rib 6, the longitudinal ribs 4 are welded to the weltering surface steel plate 1, and the collision surface steel 2, the top plate 3, and constitute a steel housing with the vertical rib 6, and the internal perfusion regeneration buffer suction material 5. A plurality of vertical ribs 4 and vertical ribs 6 are provided. Welcome surface steel plate 1, non-welcoming surface steel plate 2, top plate 3 and longitudinal ribs 4, etc. can be used to facilitate transportation of small segments.

[0059] The guardrail is mounted on the steel beam 11 with a weltering surface steel plate 1 with longitudinal rib 4, and the non-weltering surface steel 2 with longitudinal ribs 4 and th...

Embodiment 3

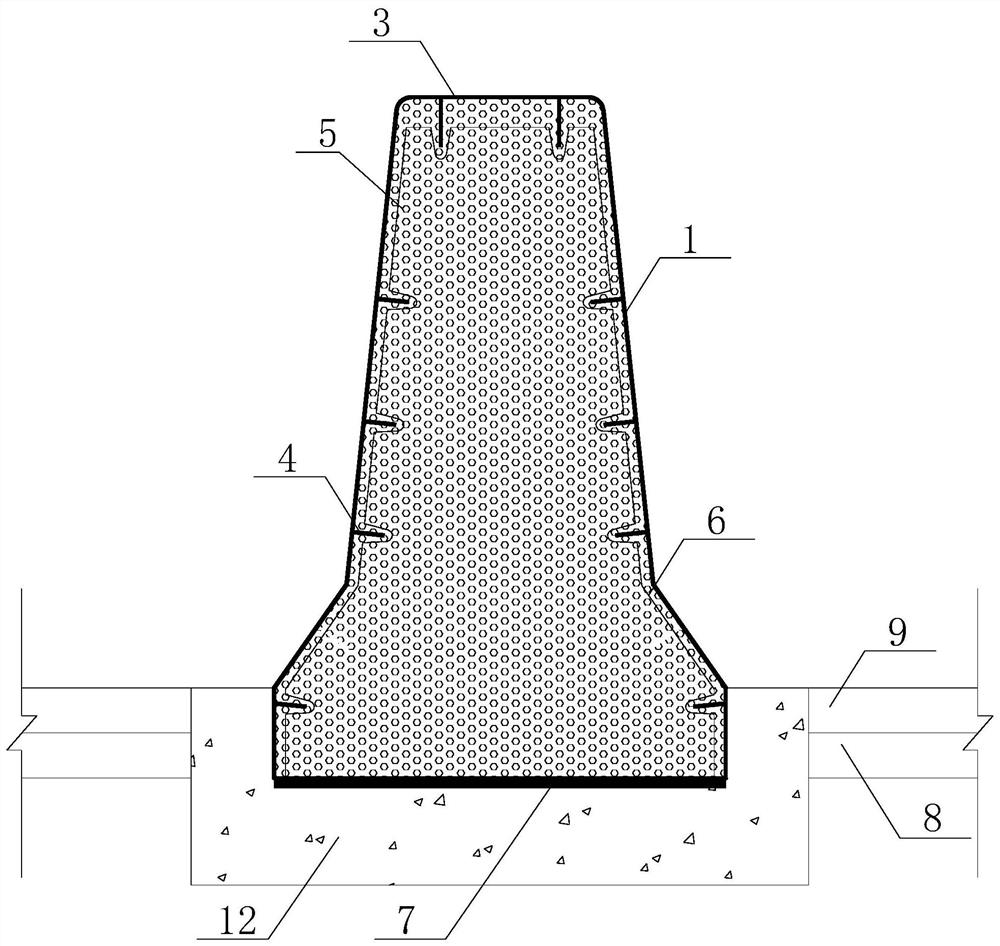

[0061] Such as image 3 As shown, the composite buffer anti-collision guardrail based on construction waste reuse is provided, including a strike surface steel plate 1, a non-welcoming surface steel plate 2, a top plate 3, a longitudinal rib 4, regenerated buffer absorbent material 5, and vertical To the rib 6, the longitudinal ribs 4 are welded to the weltering surface steel plate 1, non-welcoming face steel 2, top plate 3, and constitute a steel housing with the vertical rib 6, the internal perfusion regeneration buffer suction material 5. A plurality of vertical ribs 4 and vertical ribs 6 are provided. Welcome surface steel plate 1, non-welcoming surface steel plate 2, top plate 3 and longitudinal ribs 4, etc. can be used to facilitate transportation of small segments.

[0062] The guardrail is mounted on the integral central isolation belt with a weltering surface steel plate 1 with longitudinal rib 4 with a non-welcoming surface steel plate 2 with longitudinal rib 4 and a vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com