Method for preventing and controlling cracks of hollow wallboard for building

A technology for hollow wall panels and construction, which is applied in construction, building maintenance, building construction, etc. It can solve the problems of wall panels sinking slowly, inconvenient operation, and the bottom seam of wall panels is empty, so as to eliminate material shrinkage, and can The effect of strong operability and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

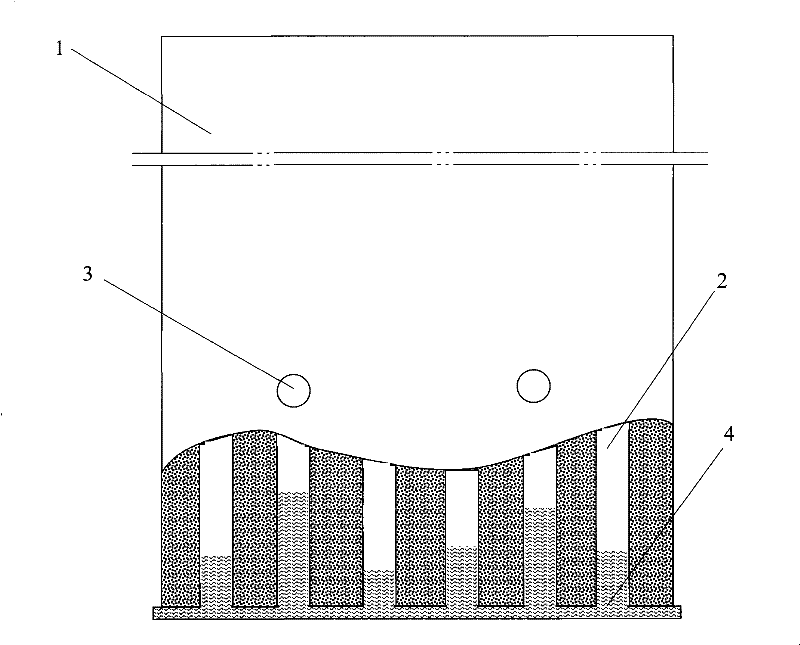

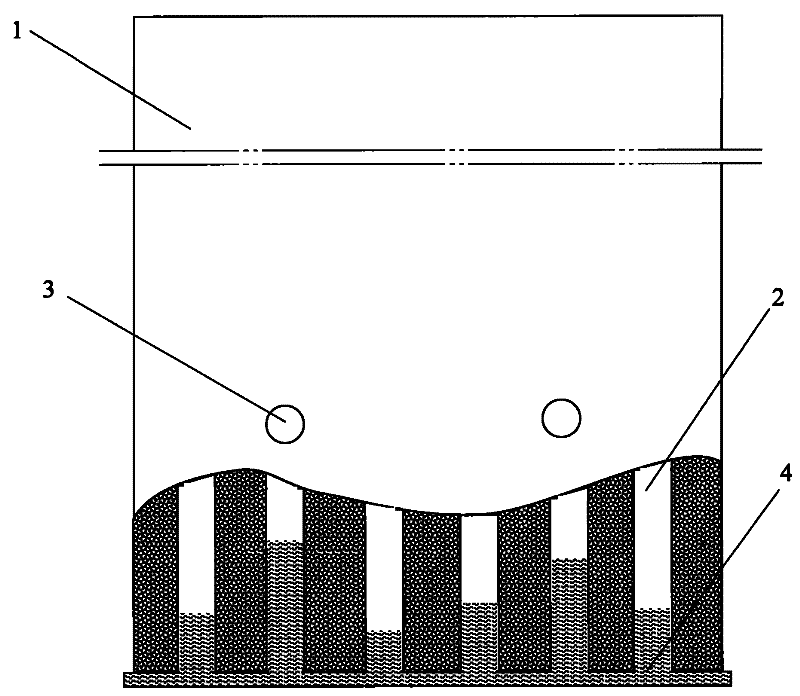

[0019] Example 1: Construction of hollow slabs on interior walls

[0020] 1. Prevention and control of wall panel settlement cracks:

[0021] (1) The process points to be changed in the wall panel installation operation are as follows:

[0022] a. The part where the wallboard is installed should be cleaned and must be sprinkled with water to moisten it.

[0023] b. When erecting the wallboard and basically in place during the installation of the wallboard, drill 1 to 2 holes at a distance of 10 to 30 cm from the lower edge of the wallboard for grouting (Note: Drill holes before erecting the wallboard , will possibly damage the wall panel).

[0024] c. Wooden wedges should be placed on the four corners of the lower end of the wallboard as much as possible, and wooden wedges with a certain thickness at the end should be selected to reduce the amount of wooden wedges inserted, ensure that the space at the lower edge of the wallboard is as open as possible, and make the slurry f...

Embodiment 2

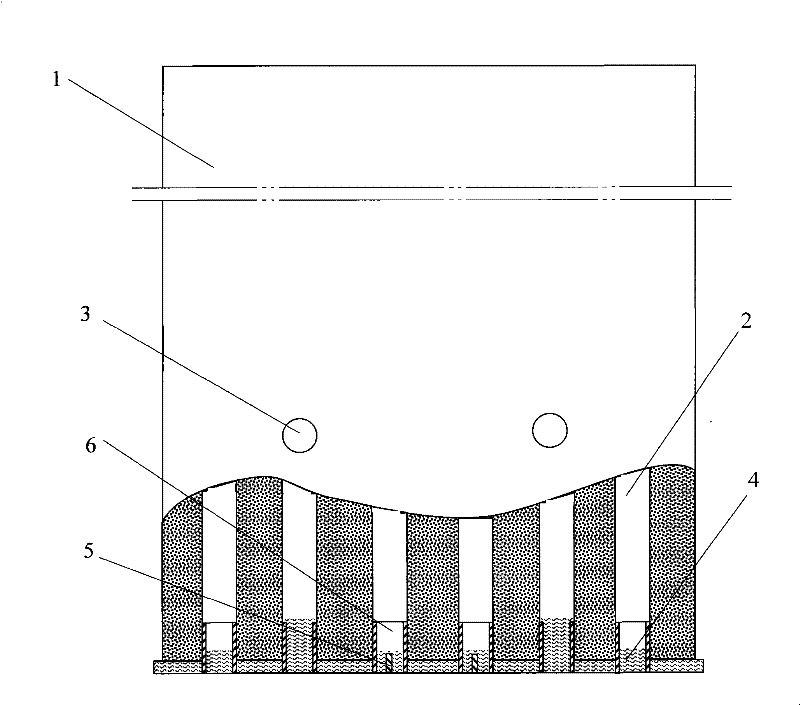

[0042] Example 2: Construction of hollow-core slabs on exterior walls

[0043] Front procedure is identical with embodiment 1, and back procedure difference is, see figure 2 , In the construction of the hollow panel of the outer wall, the wall panel reinforced with steel bars (steel wire) should be used as the outer wall panel. The difference from the installation of the inner wall panel is: on the concrete floor where the wall panel 1 is installed, first fix the steel clip 5, the steel clip 5 is facing the hollow cavity 2 of the wall panel 1, and put a round clip on the steel clip 5. The steel pipe section 6 is poured with mortar 4 again. In this way, the wall panel and the floor slab can be firmly connected together, which ensures the safety of the outer wall panel. And the process of pouring mortar of the present invention solves the waterproof problem of the bottom seam of the lightweight hollow partition wall panel of the outer wall, and the outer wall needs to be wipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com