A prefabricated steel pipe concrete support and its manufacturing method

A steel tube concrete and prefabricated technology, applied in the field of support, can solve the problems of support failure, insufficient bending bearing capacity, and quantitative yielding, etc., and achieve the effect of broad application prospects, avoiding difficult compaction, and convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] The present invention provides an assembled concrete-filled steel tube support and a manufacturing method. In order to make the object, technical scheme and effect of the invention clearer and clearer, the invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the invention, not to limit the invention. The specific implementation is as follows:

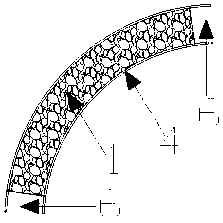

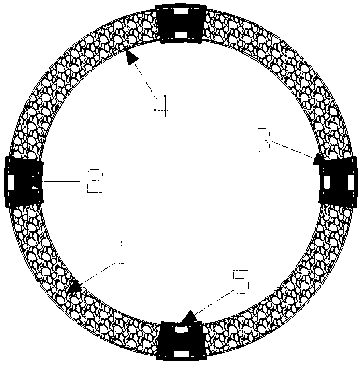

[0029] An assembled concrete-filled steel tube support and a manufacturing method, the manufacturing method comprising the following steps: ① According to the shape of the roadway to be supported, prefabricated steel tube self-compacting concrete members ( figure 1 overall), cylindrical rubber pressure-bearing body (2), cup-shaped fixed block (3) and casing (5); figure 1 The whole) non-filling section (6) is placed into the cup-shaped fixed block (3); ③ Insert the cylindrical rubber pressure-bearing body (2) into the cup-shaped fixed bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com