Anti-crack pumping concrete, and preparation method and pumping method thereof

A pumping concrete and pumping technology, which is applied in construction, building material processing, building construction, etc., can solve the problems of limited internal space pattern of buildings, poor concrete durability, low concrete strength, etc., and achieve the reduction of concrete structure Cracks, excellent slump, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A preparation method of high-strength crack-resistant pumped concrete is carried out according to the following steps:

[0048] (1) Coarse aggregate, fine aggregate, fly ash, S95 grade slag powder, micro silica fume and cement are mixed to obtain a premix;

[0049] (2) Add water and polycarboxylate superplasticizer to the premix, mix well, then add polypropylene fiber and mix well to obtain high-strength crack-resistant pumped concrete.

[0050] The invention also provides a pumping method for high-strength crack-resistant pumping concrete.

[0051] The pumping method is:

[0052] (1) Carry out a test pump test first to verify the pumping height of the concrete.

[0053] First of all, pump pipes are erected on the test site, and a total of 10 right-angle joints are installed, 8 in the horizontal direction and 2 in the vertical direction. The total length of the pump pipe exceeds 100m, 90 meters in the horizontal direction and 20 meters in the vertical direction. 2011...

Embodiment 1

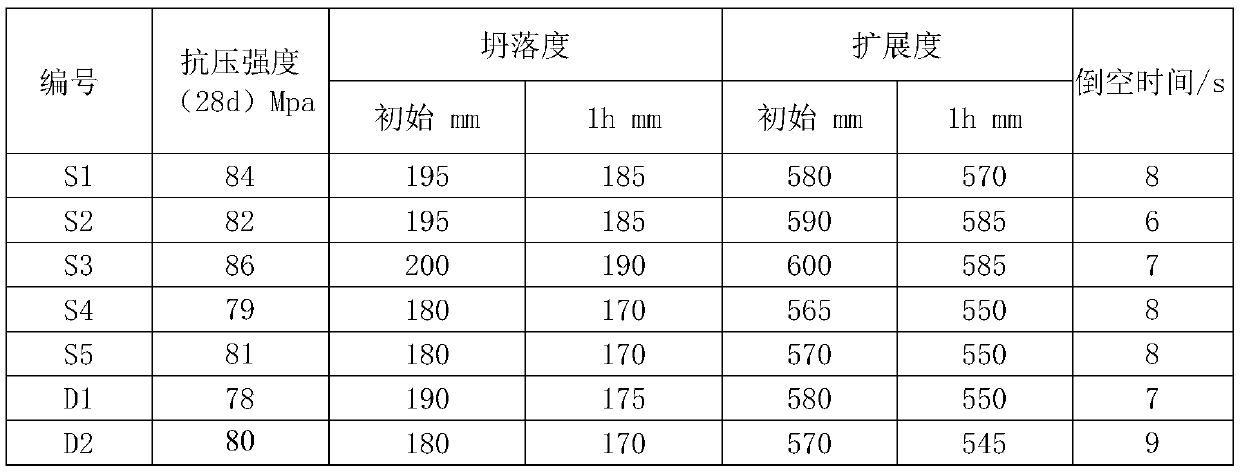

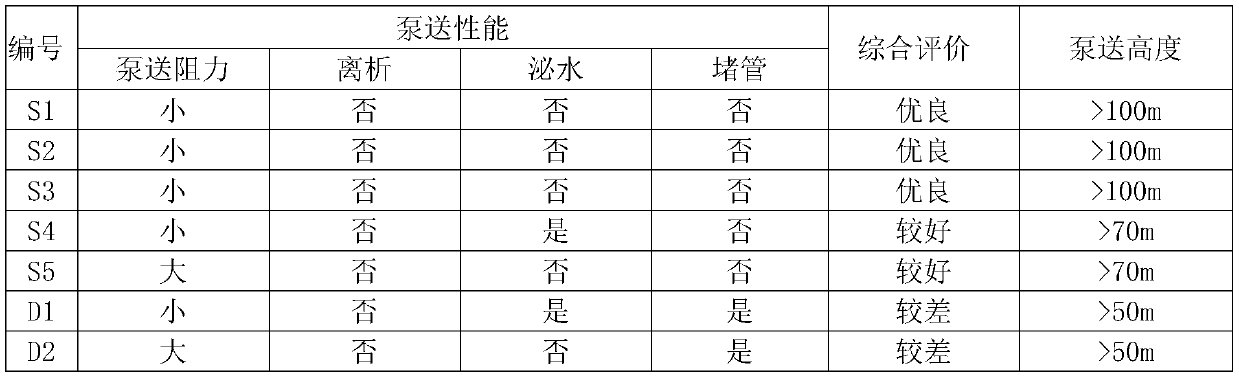

[0057] (1) According to the proportions of each group shown in Table 1, weigh coarse aggregate, fine aggregate, fly ash, S95 grade mineral powder, microsilica fume and ordinary Portland cement, and add them to the mixer for stirring 2- 3 minutes, obtain premix; Wherein, the numerical unit of each component in the table is weight part; Described cement strength grade is Portland cement of 52.5; Coarse aggregate is crushed stone of 5-20mm; Described fine bone The fineness modulus of the material is medium sand of 2.6-3.0, and the mud content is less than 2%; the fly ash is Class I fly ash.

[0058] (2) Weigh water and polycarboxylate superplasticizer into the premix, mix well, then add polypropylene fiber and mix well to obtain high-strength crack-resistant pumped concrete S1-S5, D1-D2.

[0059] Table 1

[0060] Portland cement Coarse aggregate fine aggregate fly ash S95 grade mineral powder Silica fume Polypropylene fibers Superplasticizer water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com