Device and method for driving pre-stressed anchor rod in tunnel with water-rich, soft and broken surrounding rock

A technology of crushing surrounding rock and prestressing, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve problems such as fracture and easy failure of bolts, and achieve the goal of improving bearing capacity, service life and strengthening firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

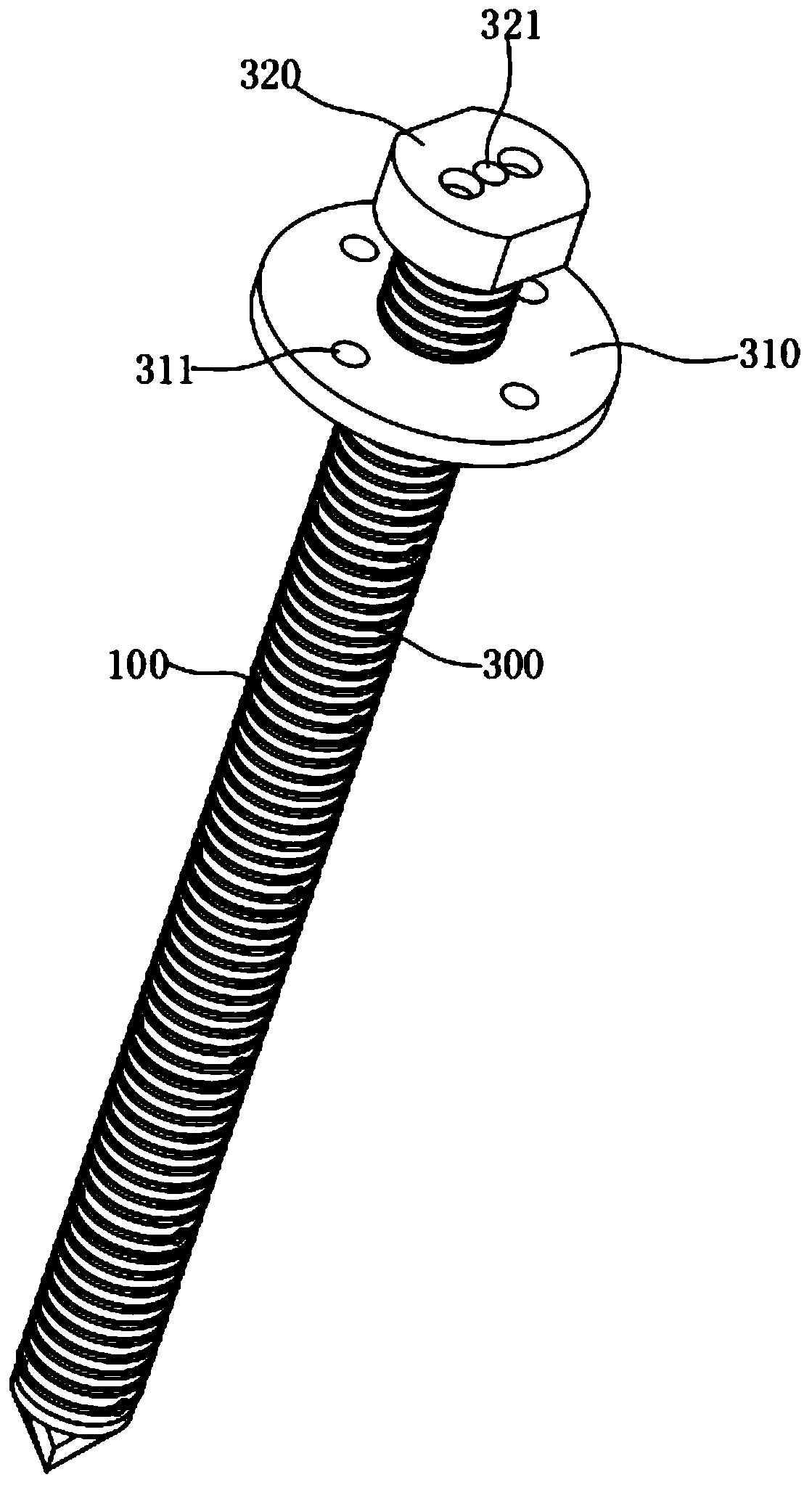

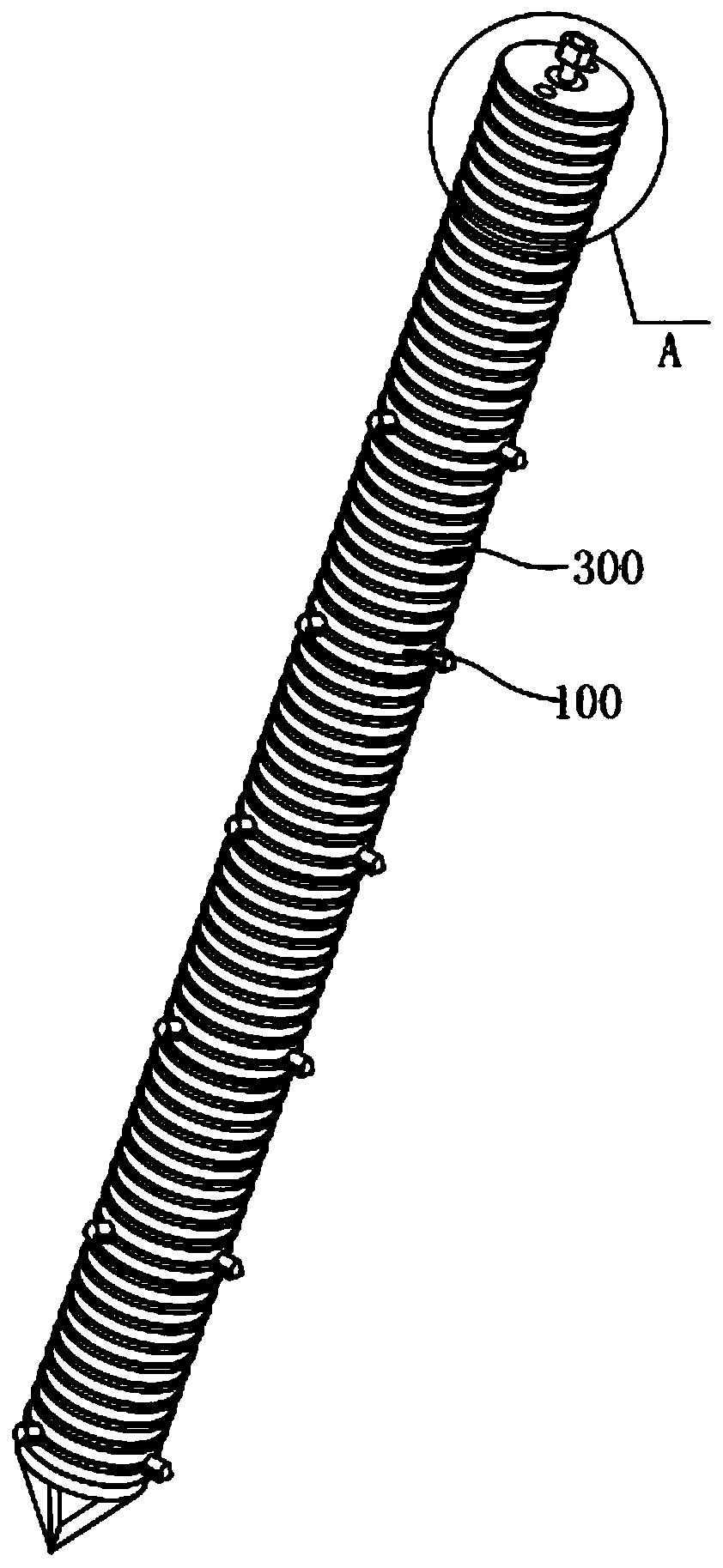

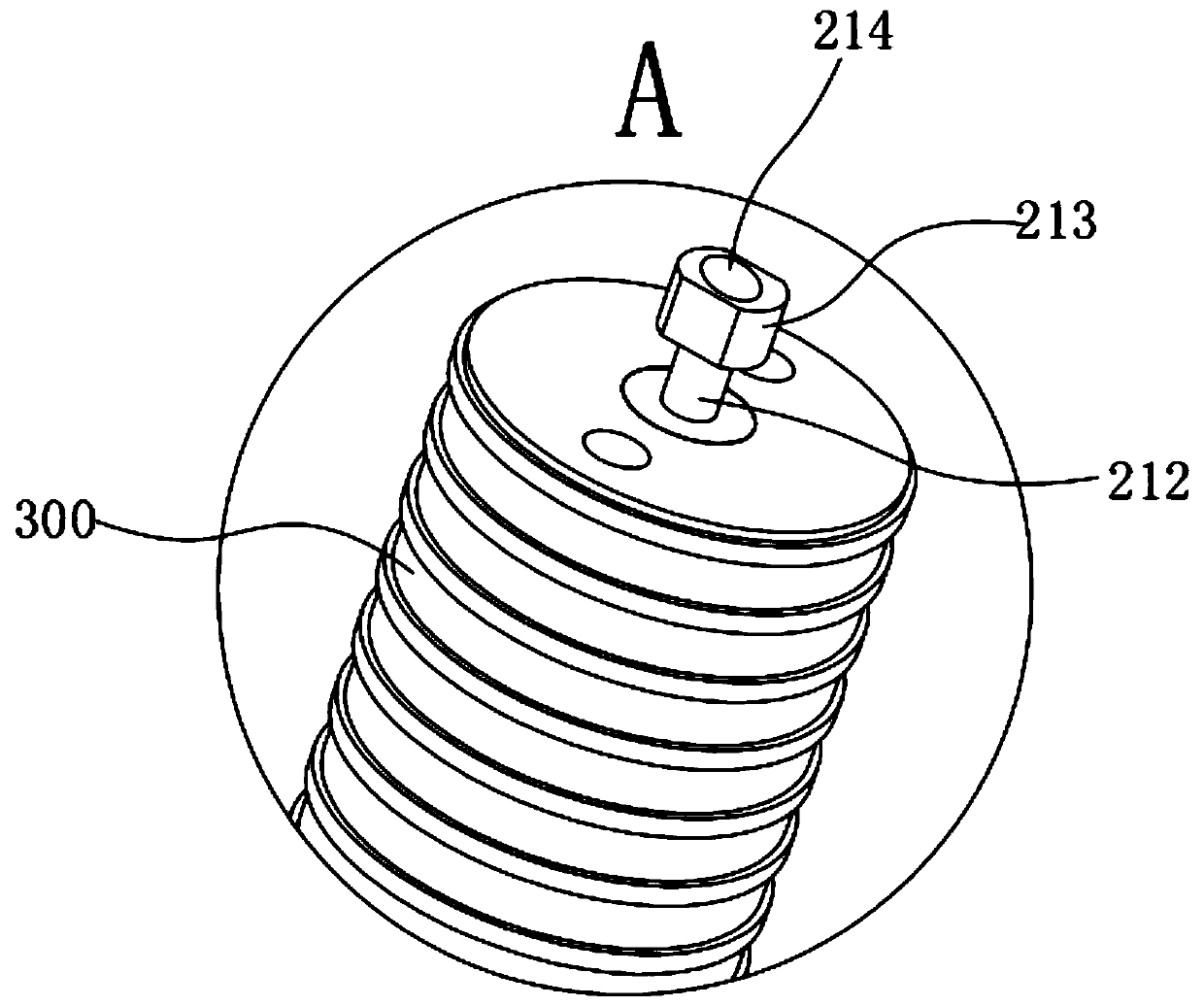

[0040] see figure 1 , Figure 4 with Image 6 , the present invention provides a technical solution: a device for setting prestressed bolts in water-rich, weak and broken surrounding rock tunnels, including a locking mechanism 100, and the locking mechanism 100 includes a mounting seat 110, a screw rod 111, a nut 112, a locking rod 113 and the through hole 114, the nut 112 is threadedly connected on the screw rod 111, the nut 112 is fixed on one end of the locking rod 113, the locking rod 113 slides in the through hole 114, and the through hole 114 is opened on the outer wall of the mounting seat 110 superior;

[0041] see Figure 4 In order to prevent the locking rod 113 from slipping out of the screw rod 111 when it moves forward, a limiting block 115 is fixed at the end of the screw rod 111 away from the first bevel gear 210, and the limiting block 115 is located in the middle of the locking rod 113, so that The position block 115 realizes the position limitation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com