A method for producing multi-functional concrete by utilizing domestic waste power generation waste slag

A domestic waste, multi-functional technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as air pollution and water pollution, and achieve low cost, convenient construction, energy and resource saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

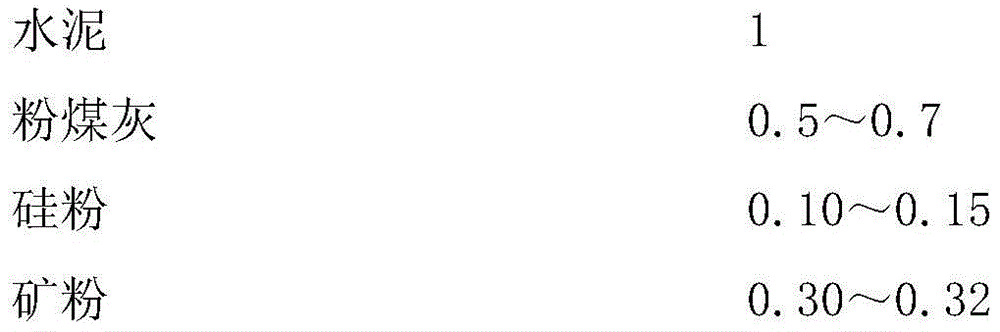

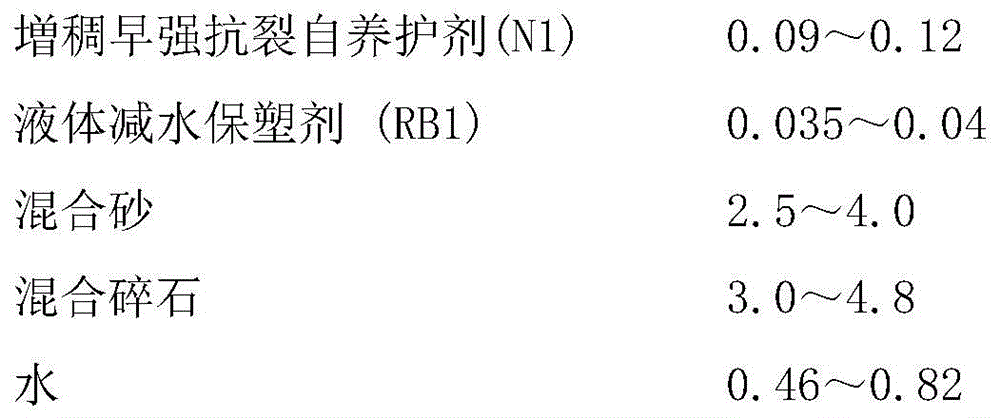

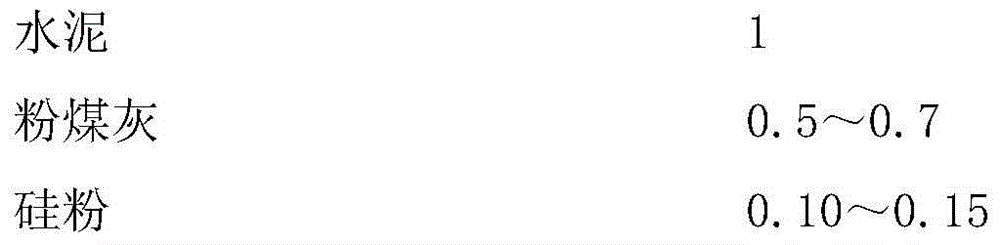

[0023] Embodiment one: prepare C30 multifunctional concrete:

[0024] (1) Mix domestic waste power generation waste slag with a particle size of ≤5mm and natural sand with a particle size of ≤5mm, the mixing ratio is: domestic waste power generation waste slag:natural sand=1:1, to obtain mixed sand; Waste residue from waste-to-energy generation is mixed with crushed stones with a particle size of 5 mm to 25 mm. The mixing ratio is: waste residue from domestic waste-to-power generation: crushed stone = 1:4 to obtain mixed crushed stone;

[0025] (2) natural zeolite powder is mixed with brucite fiber, and mixing ratio is: natural zeolite powder: brucite fiber=10:3, makes thickening early strong anti-cracking self-curing agent;

[0026] (3) Mix 100 parts of polycarboxylate high-efficiency water reducer with a solid content of 30% and 25 parts of mineral superfine powder, the mineral superfine powder is silicon powder, and stir evenly to obtain a liquid water-reducing and plastic-...

Embodiment 2

[0030] Embodiment two: prepare C40 multifunctional concrete:

[0031] (1) Mix domestic waste power generation waste slag with a particle size of ≤5mm and natural sand with a particle size of ≤5mm, and the mixing ratio is: domestic waste power generation waste slag:natural sand=1:1.2 to obtain mixed sand; The waste residue from domestic waste power generation is mixed with crushed stones with a particle size of 5 mm to 25 mm. The mixing ratio is: waste residue from domestic waste power generation: crushed stone = 1:3.5 to obtain mixed crushed stones;

[0032] (2) natural zeolite powder is mixed with brucite fiber, and mixing ratio is: natural zeolite powder: brucite fiber=10:2.5, makes thickening early strong anti-cracking self-curing agent;

[0033] (3) Mix 100 parts of polycarboxylate high-efficiency water reducer with a solid content of 30% and 25 parts of mineral superfine powder, and the mineral superfine powder is high in clay powder, and stir evenly to obtain a liquid wa...

Embodiment 3

[0037] Embodiment three, preparation C50 multifunctional concrete:

[0038] (1) Mix domestic waste power generation waste slag with a particle size of ≤5mm and natural sand with a particle size of ≤5mm, the mixing ratio is: domestic waste power generation waste slag:natural sand=1:1.4, to obtain mixed sand; The waste residue from waste-to-energy generation is mixed with gravel with a particle size of 5 mm to 25 mm, and the mixing ratio is: waste residue from domestic waste power generation: gravel = 1:3.8 to obtain mixed gravel;

[0039] (2) natural zeolite powder is mixed with brucite fiber, and mixing ratio is: natural zeolite powder: brucite fiber=10:2.5, makes thickening early strong anti-cracking self-curing agent;

[0040] (3) Mix 100 parts of polycarboxylate high-efficiency water reducer with a solid content of 30% and 30 parts of mineral superfine powder, the mineral superfine powder is natural zeolite powder, and stir evenly to obtain a liquid water-reducing and plast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com