Concrete ingredient and fast hardening concrete

A concrete, fast technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of long solidification cycle, low early strength, etc., to achieve shortened curing period, high early strength, and improved flatness The effect of the indicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

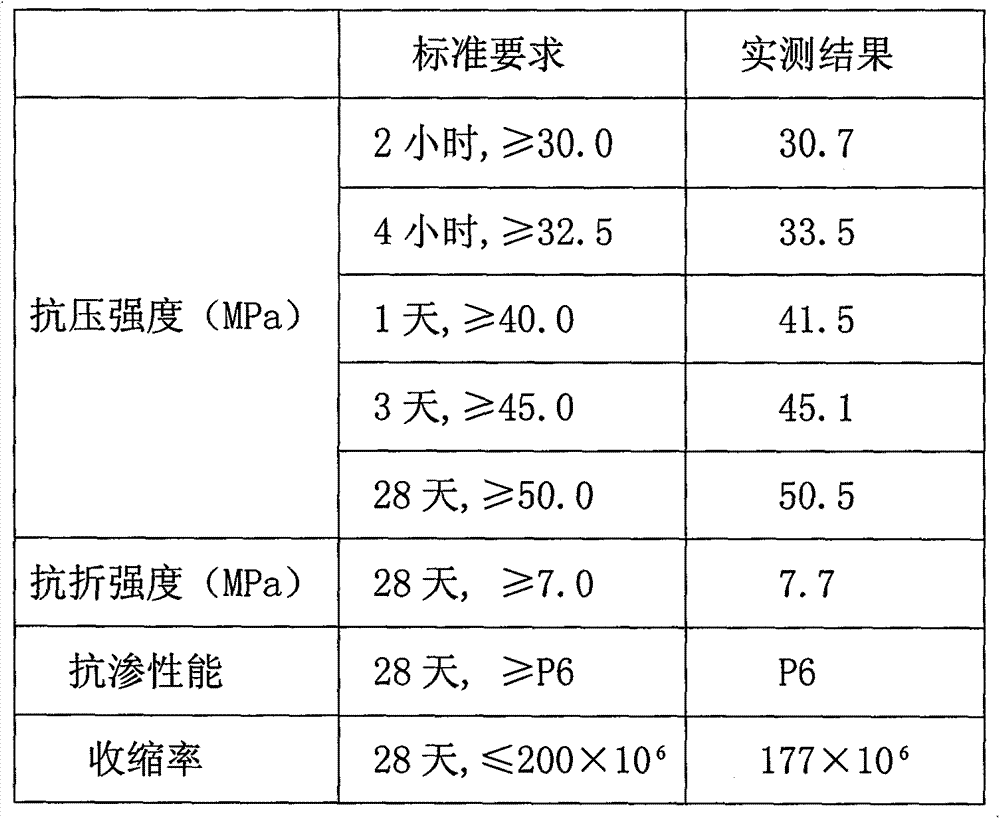

Embodiment 1

[0021] The proportions (percentages) of the concrete ingredients used in this embodiment are as follows: by weight percentage, among which: 40% of sulphur-aluminum cement, 20% of stones, 33.1% of the mixture of gold steel sand and quartz sand, shear ball-marked steel Fiber 2%, fly ash 1%, carbon black 2%, calcium sulfoaluminate cement expansion agent 0.8%, polycarboxylate high-performance water reducing agent 0.1%, sulfo-aluminum cement accelerator 1%. According to the above proportions, weigh 400Kg of sulfo-alumina cement, 200Kg of stones, 331Kg of the mixture of diamond sand and quartz sand, 20Kg of steel fiber, 10Kg of fly ash, 20Kg of carbon black, 8Kg of calcium sulfoaluminate cement expansion agent, polycarboxylate Acid-based high-performance water reducer 1Kg, sulfur-aluminum cement accelerator 10Kg. Among them: the model or label of sulphur-aluminum cement is: 525#, which can be determined according to the grade of the road in actual use. For example, a high grade is u...

Embodiment 2

[0023] The proportions of concrete ingredients used in this embodiment are as follows: by weight percentage, in which: 36% of sulphur-aluminum cement, 22% of granite crushed stone, 34% of the mixture of gold steel sand and quartz sand, 2.2% of shear ball-shaped steel fiber %, fly ash 1%, carbon black 2.5%, calcium sulfoaluminate cement expansion agent 1%, polycarboxylic acid-based high-performance water reducing agent 0.1%, sulfo-aluminum cement accelerator 1.2%. According to the above ratio, weigh 360Kg of sulphoaluminum cement, 220Kg of stones, 340Kg of the mixture of gold steel sand and quartz sand, 22Kg of steel fiber, 10Kg of fly ash, 25Kg of carbon black, 10Kg of calcium sulfoaluminate cement expansion agent, polycarboxylate Acid-based high-performance water reducer 1Kg, sulfur-aluminum cement accelerator 12Kg. Among them: the model or label of sulphur-aluminum cement is: 525#, which can be determined according to the grade of the road in actual use. For example, a high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com