Grouting material for building joints prepared by wet grinding

A technology for grouting materials and connectors, applied in the field of building materials, can solve the problems of high cost of steel grouting materials, easy rusting of steel bars, etc., and achieve the effects of improving grinding performance, reducing steel corrosion, and avoiding steel corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

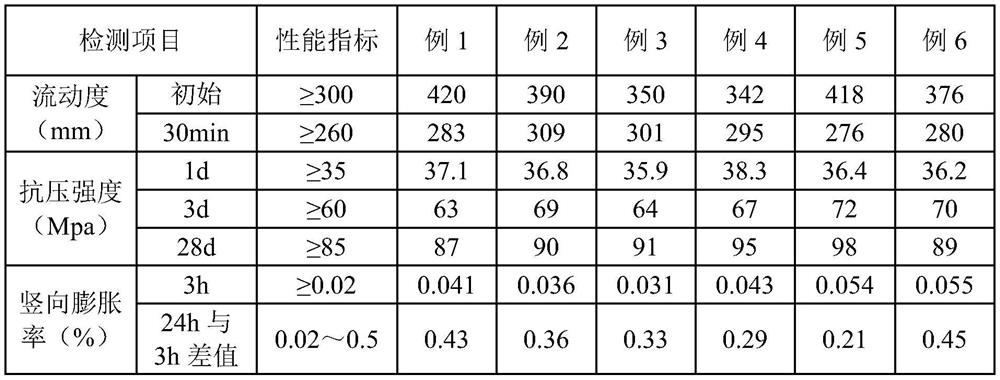

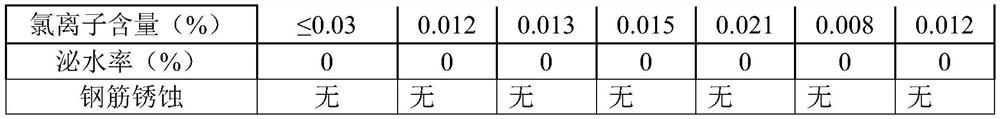

Examples

Embodiment 1

[0027] 1) Take 35 parts by weight of slag and 20 parts of steel slag, add water according to the water-solid weight ratio of 0.15 to obtain a mixture, put the mixture into a wet mill for collaborative wet grinding, and obtain a mixed slurry material with an average particle size of 2 μm to 7 μm.

[0028] 2) Take 10 parts by weight of carbide slag, 2 parts of desulfurized gypsum, and 5 parts of silica fume and add them to a dry mill for grinding to obtain a mixed powder material with an average particle size of <30 μm;

[0029] 3) Mix the mixed slurry material obtained in step 1) with the mixed powder material obtained in step 2) to obtain a mixture, add 1 part by weight of SAP to the mixture, 80 parts of tailing sand, 85 parts of cement, wood 0.5 part of sulfonic acid water reducing agent, 0.5 part of calcium nitrite-calcium nitrate early strength agent; after adding water, the water-solid weight ratio is 0.15, first stir slowly in the mixer for 2 minutes, and then stir quickly...

Embodiment 2

[0031] 1) Take 36 parts by weight of slag and 21 parts of steel slag, add water according to the water-solid weight ratio of 0.16 to obtain a mixture, put the mixture into a wet mill for collaborative wet grinding, and obtain a mixed slurry material with an average particle size of 2 μm to 7 μm.

[0032] 2) Take 11 parts by weight of carbide slag, 2 parts of desulfurized gypsum, and 6 parts of silica fume and add them to a dry mill for grinding to obtain a mixed powder material with an average particle size of <30 μm;

[0033]3) Mix the mixed slurry material obtained in step 1) with the mixed powder material obtained in step 2) to obtain a mixture, add 1 part by weight of SAP to the mixture, 90 parts of tailings sand, 86 parts of cement, wood 0.6 part of cotton pulp water reducer, 0.6 part of calcium nitrate-urea early strength agent; after adding water according to the water-solid weight ratio of 0.16, stir slowly in the mixer for 2 minutes, and then stir quickly for 2 minutes...

Embodiment 3

[0036] 1) Take 37 parts by weight of slag and 22 parts of steel slag, add water according to the water-solid weight ratio of 0.17 to obtain a mixture, put the mixture into a wet mill to cooperate with wet grinding, and obtain a mixed slurry material with an average particle size of 2 μm to 7 μm.

[0037] 2) Take 13 parts by weight of carbide slag, 2 parts of desulfurized gypsum, and 7 parts of silica fume and add them to a dry mill for grinding to obtain a mixed powder material with an average particle size of <30 μm;

[0038] 3) Mix the mixed slurry material obtained in step 1) with the mixed powder material obtained in step 2) to obtain a mixture, add 2 parts by weight of SAP, 95 parts of tailing sand, 87 parts of cement, and half 0.5 part of cellulose-based water reducer, 0.5 part of calcium nitrate-urea early strength agent; after adding water according to the water-solid weight ratio of 0.15, first stir slowly in the mixer for 2 minutes, and then stir quickly for 2 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com