Super-early-strength high-ductility cement based composite material and preparation method thereof

A composite material and high ductility technology, applied in the field of building materials, can solve the problems of poor economic and social benefits, low strength of polymer materials, deformation and inconsistent structure, etc., to achieve excellent working performance, good working performance and high late performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

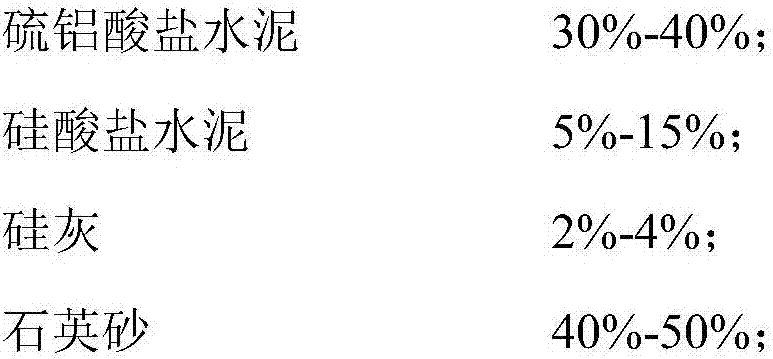

[0034] A super-early-strength and high-ductility cement-based composite material for rapid repair and a preparation method thereof, comprising the following steps:

[0035] (1) Prepare raw materials according to the following weight percentages: 35.7% of sulfoaluminate cement; 10.9% of Portland cement; 45.9% of quartz sand; 3.0% of steel fiber; 3.4% of silica fume; %; retarder 0.80%; early strength agent 0.07%.

[0036] (2) First add various raw materials to a forced mixer with a rotation speed of 30-60r / min and stir evenly, then add corresponding water for stirring for 5-10 minutes, and then super early strength and high ductility cement-based composite materials can be obtained.

Embodiment 2

[0038] A method for preparing a super-early-strength and high-ductility cement-based composite material for rapid repair, comprising the following steps:

[0039] (1) Prepare raw materials according to the following formula: 35.0% of sulfoaluminate cement; 10.8% of Portland cement; 46.0% of quartz sand; 4.0% of steel fiber; 3.2% of silica fume; ; Set retarder 0.72%; Early strength agent 0.05%.

[0040] (2) First add various raw materials into a forced mixer with a rotation speed of 30-60r / min and stir evenly, then add corresponding water for stirring for 5-10 minutes, and super early strength and high ductility cement-based composite materials can be obtained.

Embodiment 3

[0042] A method for preparing a super-early-strength and high-ductility cement-based composite material for rapid repair, comprising the following steps:

[0043] (1) Prepare raw materials according to the following formula: 37.5% of sulfoaluminate cement; 10.8% of Portland cement; 42.5% of quartz sand; 5.0% of steel fiber; 3.2% of silica fume; ; Set retarder 0.71%; Early strength agent 0.06%.

[0044] (2) First add various raw materials into a forced mixer with a rotation speed of 30-60r / min and stir evenly, then add corresponding water for stirring for 5-10 minutes, and super early strength and high ductility cement-based composite materials can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com