A kind of waterproofing agent mixed with cement concrete and preparation method thereof

A technology of cement concrete and waterproofing agent, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems affecting the early strength of concrete, poor waterproof effect, easy moisture absorption failure, etc., to reduce permeability and electric flux, reduce water absorption, and improve the effect of concrete compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

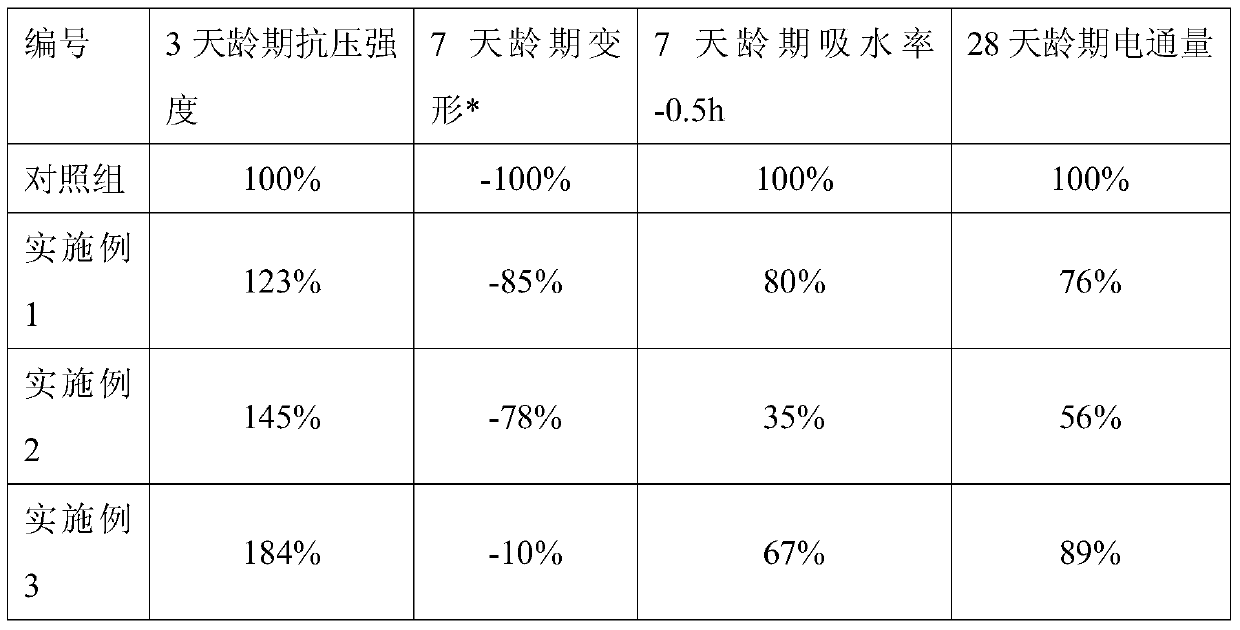

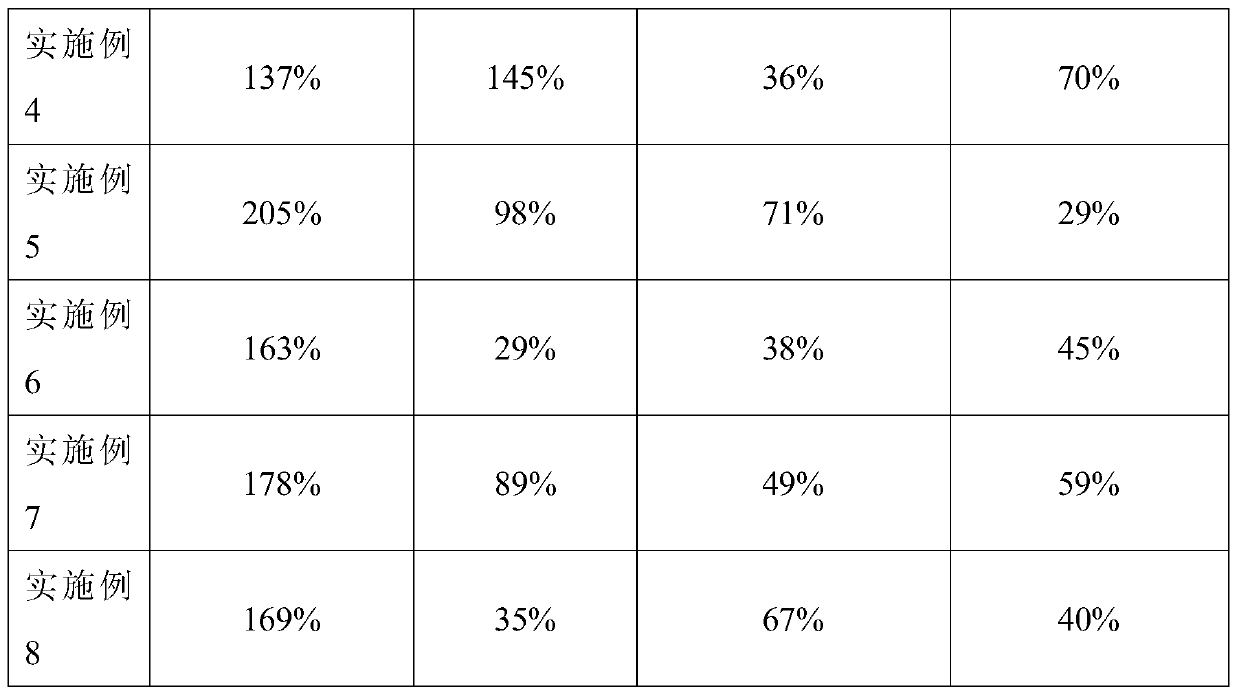

Examples

Embodiment 1

[0025] Weigh 0.1 part of Tween-80 and 0.1 part of Span-80, dissolve and disperse with appropriate water, add 0.2 part of octyltriethoxysilane, stir at 25°C for 1 hour to form a dispersion; add 0.2 part of specific surface area 50m 2 / g of aluminum oxide nanopowder and 0.05 parts specific surface area is 400m 2 / g silica, 0.05 parts specific surface area is 0.01m 2 / g fly ash, after stirring for 20min, make up the remaining water to obtain waterproofing agent 1.

Embodiment 2

[0027] Weigh 1 part of Tween-60, dissolve and disperse with appropriate water, add 1 part each of stearic acid and dodecyltrimethoxysilane, heat up to 100°C, stir for 2 hours to form a dispersion; cool the above dispersion to 35°C, add 2 parts with a specific surface area of 10m 2 / g of aluminum oxide nanopowder, 3 parts with a specific surface area of 50m 2 / g calcium carbonate and 1 part specific surface area is 5m 2 / g fly ash, after stirring for 10min, make up the remaining water to obtain waterproofing agent 2.

Embodiment 3

[0029] Weigh 1 part of Tween-20 and 1 part of Span-60, dissolve and disperse with appropriate water, add 5 parts of zinc stearate and 5 parts of lauryl alcohol, heat up to 85°C and stir for 1 hour to form a dispersion; cool down After reaching 45°C, add 10 parts with a specific surface area of 150m 2 / g of aluminum oxide nanopowder and 5 parts with a specific surface area of 0.02m 2 / g silica, 5 parts specific surface area is 0.5m 2 / g fly ash, after stirring for 60min, make up the remaining water to obtain waterproofing agent 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com