Mineral inorganic superfine foamed filling material as well as preparation method and application method of mineral inorganic superfine foamed filling material

A filling material and inorganic technology, applied in the field of mineral inorganic ultra-fine foamed filling materials and their preparation, can solve the problems of hidden dangers of coal mine production, unfavorable coal mine production, and high reaction temperature, and achieve good transportability and injectability. , low cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

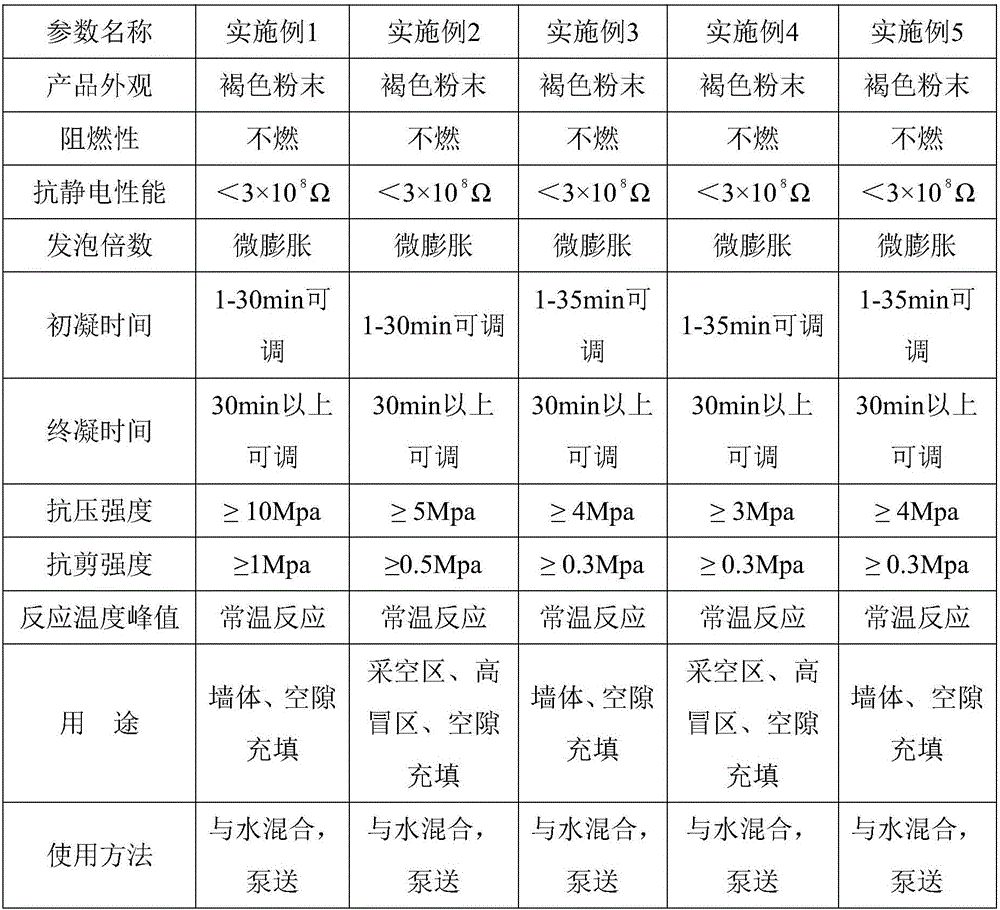

Examples

Embodiment l

[0029] An inorganic ultra-fine foam filling material for mining, which is composed of the following raw materials in parts by weight: 15 parts of sulfoaluminate cement, 37 parts of bentonite, 7 parts of perlite, 36 parts of fly ash, 4.5 parts of foaming agent and 0.5 part of water agent, the foaming agent is vegetable protein foaming agent, and the water reducer is calcium lignosulfonate.

[0030] The preparation method of the inorganic ultra-fine foam filling material for mines described in this embodiment includes the following steps: prepare the raw materials according to the proportion, respectively mix sulphoaluminate cement, bentonite, perlite, fly ash, foaming agent and reducing The water preparation is finely ground, and the particle size range of each raw material is 40 μm to reach more than 95%, and then the raw materials are mixed evenly to obtain a uniformly dispersed composite powder product, which can be repacked; in order to speed up the mixing efficiency, the mi...

Embodiment 2

[0033] An inorganic ultra-fine foam filling material for mining is composed of the following raw materials in parts by weight: 12 parts of sulfoaluminate cement, 37 parts of bentonite, 5 parts of perlite, 40 parts of fly ash, 5 parts of foaming agent and 1 part of water agent, the foaming agent is vegetable protein foaming agent, and the water reducer is calcium lignosulfonate.

[0034] The preparation method of the inorganic ultra-fine foam filling material for mines described in this embodiment includes the following steps: prepare the raw materials according to the proportion, respectively mix sulphoaluminate cement, bentonite, perlite, fly ash, foaming agent and reducing The water preparation is finely ground, and the particle size range of each raw material is 40 μm to reach more than 95%, and then the raw materials are mixed evenly to obtain a uniformly dispersed composite powder product, which can be repacked; in order to speed up the mixing efficiency, the mixing is in ...

Embodiment 3

[0037] An inorganic ultra-fine foam filling material for mining is composed of the following raw materials in parts by weight: 18 parts of sulphoaluminate cement, 40 parts of bentonite, 5 parts of perlite, 30 parts of fly ash, 6.7 parts of foaming agent and 0.3 part of water agent, the foaming agent is an animal protein foaming agent, and the water reducer is calcium lignosulfonate.

[0038] The preparation method of the inorganic ultrafine foam filling material for mining described in this embodiment is the same as that in Embodiment 1.

[0039] The method of using the inorganic ultrafine foam filling material for mines described in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water reduction rate | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com